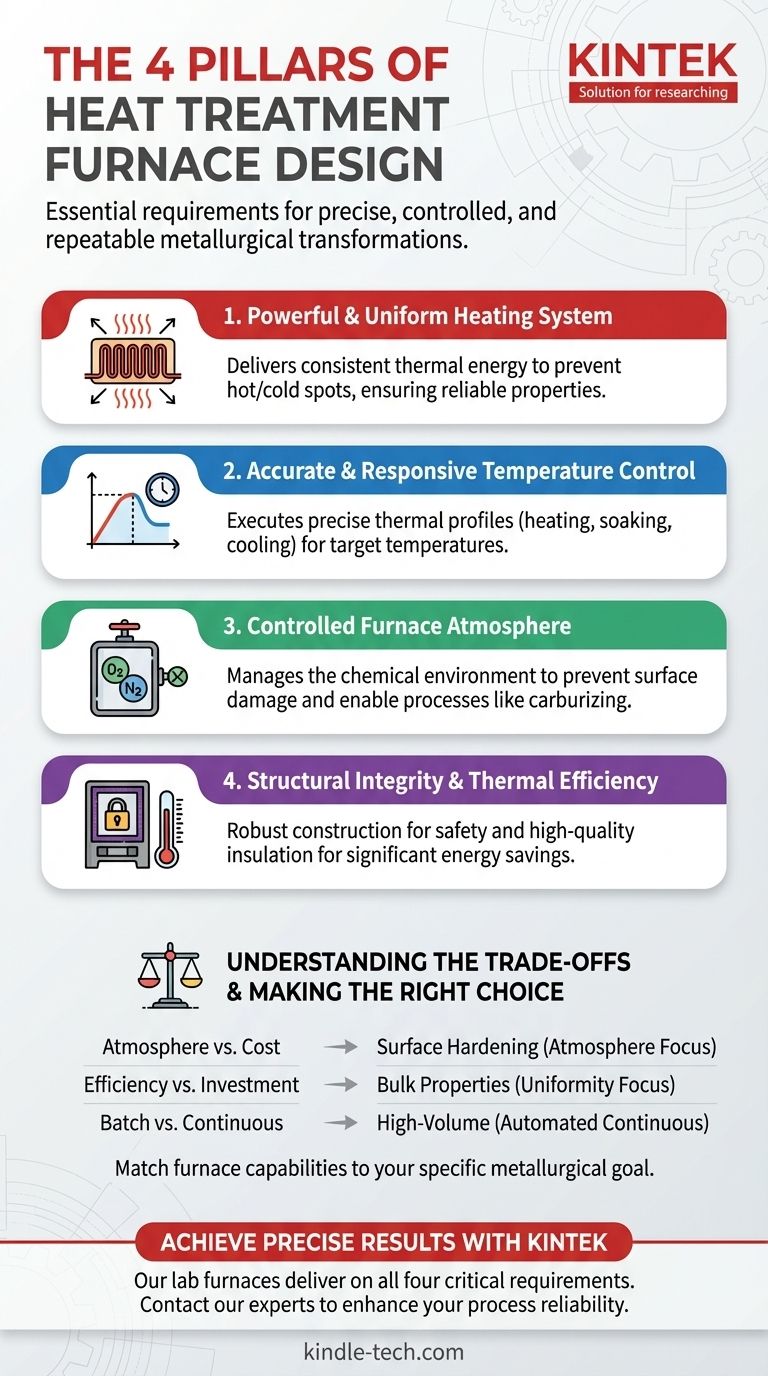

At its core, a heat treatment furnace must reliably deliver four fundamental capabilities. These requirements are a precise heating system, accurate temperature control over time, a managed furnace atmosphere, and the structural integrity to safely contain the entire process. Without any one of these, the furnace cannot achieve the controlled metallurgical transformations that are the sole purpose of heat treatment.

The essential function of a heat treatment furnace is not merely to get hot, but to create a highly controlled and repeatable environment. The four key requirements are the pillars that enable the precise manipulation of a material's core properties through the careful application of heat and chemistry.

The Four Pillars of Furnace Design

To understand why these requirements are non-negotiable, we must look at the function each one serves in achieving a specific metallurgical outcome. They work in concert to transform a material from its initial state to its desired final state.

1. A Powerful and Uniform Heating System

The most obvious requirement is the ability to generate heat. The system, whether gas-fueled or electric, must be capable of delivering sufficient thermal energy to raise the temperature of the workload to the target level within a practical timeframe.

The true challenge, however, is heat uniformity. Cold spots or hot spots within the furnace will result in inconsistent material properties, rendering the entire process unreliable. This is why the design and placement of heating elements are critical.

2. Accurate and Responsive Temperature Control

Generating heat is insufficient; you must control it with precision. Heat treatment processes follow a specific thermal profile, often involving a rapid heating period, a long "soaking" or holding period at a specific temperature, and a controlled cooling phase.

The furnace's control system must regulate the heat source to execute this profile perfectly. It needs to supply high energy during the initial heating phase and then throttle back to maintain a steady, constant temperature during the soak, ensuring the entire part achieves the target temperature.

3. A Controlled Furnace Atmosphere

The chemical environment inside the furnace is just as important as the temperature. The atmosphere directly interacts with the surface of the hot metal, and an uncontrolled atmosphere can ruin the part.

A furnace must have a well-sealed body to manage this environment. This allows operators to prevent unwanted reactions like oxidation (scaling) or to intentionally introduce specific gases to alter the material's surface, such as in carburizing processes. This is managed by dedicated ventilation and exhaust devices.

4. Structural Integrity and Thermal Efficiency

The furnace is a vessel that must safely contain extreme temperatures and potentially volatile atmospheres. Its physical construction, including the furnace body and any doors or seals, must be robust and reliable.

Furthermore, it must be efficient. A furnace top, and indeed its entire structure, must have excellent heat-preservation functionality (insulation). Poor insulation leads to massive energy waste and can create an unsafe external operating environment.

Understanding the Trade-offs

Selecting or designing a furnace involves balancing competing priorities. Understanding these trade-offs is key to making a sound technical decision.

Atmosphere vs. Air Furnaces

A furnace with a tightly sealed chamber and complex gas-handling systems is significantly more expensive and complex to operate than a simple air furnace. If the process (like simple tempering) or material is not sensitive to oxidation, a controlled atmosphere may be an unnecessary expense.

Energy Efficiency vs. Initial Cost

Higher-quality insulation and more efficient heating elements increase the upfront cost of a furnace. However, these investments pay for themselves over the operational life of the furnace through significantly lower energy consumption.

Batch vs. Continuous Processing

Furnaces designed for batch processing offer high flexibility for different part sizes and treatment cycles. Continuous furnaces, which use mechanical feeding and discharging devices, are built for high-volume production of similar parts, offering superior consistency and throughput at the cost of flexibility.

Making the Right Choice for Your Goal

Your specific metallurgical goal dictates which furnace capabilities you must prioritize.

- If your primary focus is surface hardening (e.g., carburizing): A furnace with exceptional atmosphere control and a robustly sealed chamber is non-negotiable.

- If your primary focus is bulk property changes (e.g., annealing): Prioritize a furnace with documented temperature uniformity and highly accurate process control.

- If your primary focus is high-volume production: A continuous furnace with automated material handling and integrated quenching will deliver the required consistency and efficiency.

- If your primary focus is process safety and reliability: Ensure the furnace includes certified safety interlocks, failsafe devices, and proper ventilation for the specific atmosphere being used.

Ultimately, choosing the right furnace means matching its technical capabilities to the specific material transformation you need to achieve.

Summary Table:

| Requirement | Key Function | Why It's Critical |

|---|---|---|

| Powerful, Uniform Heating | Generates and distributes heat evenly | Prevents inconsistent material properties from hot/cold spots |

| Accurate Temperature Control | Executes specific heating, soaking, and cooling profiles | Ensures the entire part achieves the target temperature for the required time |

| Controlled Furnace Atmosphere | Manages the chemical environment inside the furnace | Prevents surface damage (e.g., oxidation) and enables processes like carburizing |

| Structural Integrity & Efficiency | Safely contains the process and conserves energy | Ensures operator safety and reduces operational costs through good insulation |

Ready to achieve precise metallurgical results?

The right furnace is the foundation of successful heat treatment. At KINTEK, we specialize in designing and supplying laboratory furnaces that deliver on all four critical requirements—ensuring precise temperature control, uniform heating, reliable atmosphere management, and robust safety.

Whether your goal is annealing, carburizing, or high-volume production, our expertise in lab equipment can help you select the perfect solution for your specific material transformation needs.

Contact our experts today to discuss your application and discover how a KINTEK furnace can enhance your process reliability and efficiency.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control