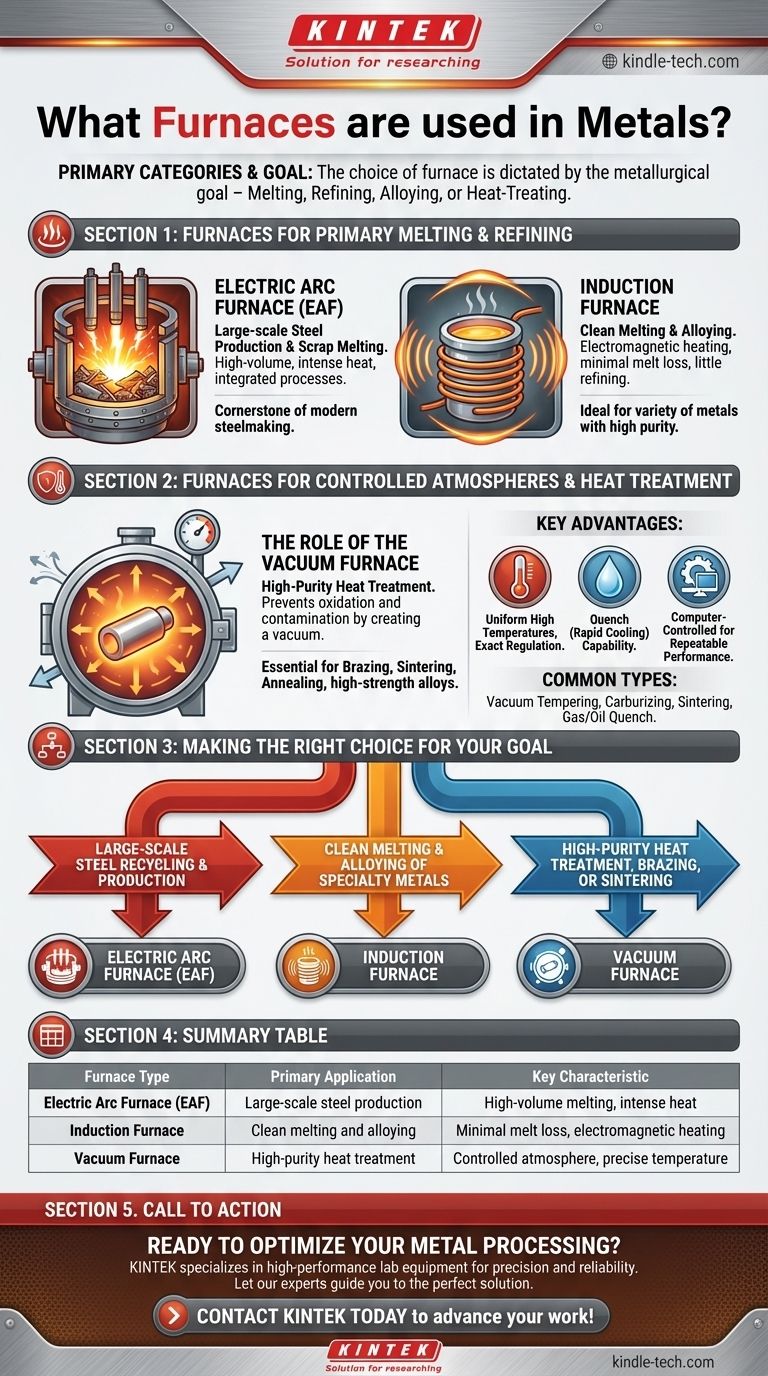

In metallurgy, several types of furnaces are used, each designed for a specific purpose, from melting raw materials to precise heat treatment. The primary categories include electric arc furnaces for large-scale steel production, induction furnaces for clean melting and alloying, and vacuum furnaces for high-purity heat treatment and processing in controlled environments.

The critical insight is not simply knowing the types of furnaces, but understanding that the choice of furnace is fundamentally dictated by the metallurgical goal—whether you are melting, refining, alloying, or heat-treating the metal.

Furnaces for Primary Melting and Refining

The first stage for many metals, particularly steel, involves melting raw materials or scrap. Furnaces in this category are designed for high temperatures and large volumes.

Electric Arc Furnace (EAF)

An electric arc furnace is a cornerstone of modern steelmaking, primarily used for melting steel scrap. It uses a high-power electric arc between graphite electrodes to generate intense heat, melting the charge material.

The development of related technologies has allowed EAFs to integrate well with traditional steel-making processes, enhancing their overall efficiency.

Induction Furnace

Induction furnaces are ideal for melting and alloying a wide variety of metals with minimal melt loss. They use electromagnetic induction to heat the conductive metal inside a crucible.

This method is exceptionally clean, but it offers very little refining of the metal, meaning impurities are generally not removed during the process.

Furnaces for Controlled Atmospheres and Heat Treatment

After a metal has been cast or formed, it often requires heat treatment to achieve specific mechanical properties. These processes demand precise control over temperature and atmosphere to prevent unwanted chemical reactions.

The Role of the Vacuum Furnace

A vacuum furnace is designed to heat metals to very high temperatures with minimal contamination. By removing the air and creating a vacuum, it prevents oxidation and eliminates reactions with gases like carbon and oxygen.

This control is essential for processes like brazing, sintering, and annealing high-strength alloys used in aerospace and medical applications.

Key Advantages

The primary benefits of vacuum furnaces are precise process control and product quality. They offer uniform high temperatures, exact temperature regulation, and the ability to quench (rapidly cool) the product.

Furthermore, these systems are often computer-controlled, ensuring that each batch is processed identically for repeatable performance.

Common Vacuum Furnace Types

The vacuum furnace category is broad, with specialized designs for specific tasks. Common types include vacuum tempering, vacuum carburizing, vacuum sintering, and both gas and oil quench furnaces for different cooling requirements.

Understanding the Core Trade-offs

Selecting the right furnace requires balancing cost, scale, and the desired final properties of the metal. No single furnace is best for every application.

Process Goal: Melting vs. Treating

The most fundamental trade-off is between melting and subsequent processing. EAFs and induction furnaces are built for the brute-force task of melting solid metal into a liquid state.

Conversely, vacuum furnaces are precision instruments. They excel at modifying the properties of an already-formed metal part in a highly controlled, non-contaminating environment.

Purity and Contamination Control

An induction furnace provides a very clean melt. However, a vacuum furnace offers the ultimate level of purity by removing the atmosphere itself, preventing any gas-metal reactions.

Combustion furnaces, which heat metal in a chamber with burners, create an atmosphere rich in oxygen and other gases. This is suitable for some melting processes but would be a significant source of contamination for sensitive heat treatments.

Scale and Throughput

An electric arc furnace is designed for mass production, capable of melting hundreds of tons of steel at a time.

In contrast, vacuum furnaces are typically batch furnaces designed for smaller loads of high-value components, from single tool room batches to slightly larger modular systems.

Making the Right Choice for Your Goal

Your specific metallurgical objective is the only factor that matters when selecting a furnace.

- If your primary focus is large-scale steel recycling and production: An Electric Arc Furnace (EAF) is the industry standard for its high-volume melting capability.

- If your primary focus is clean melting and alloying of specialty metals: An induction furnace offers excellent control over the melt with minimal material loss.

- If your primary focus is high-purity heat treatment, brazing, or sintering: A vacuum furnace provides the necessary controlled atmosphere to prevent contamination and ensure repeatable results.

Ultimately, choosing the correct furnace is about matching the equipment's core strengths to your specific process requirements.

Summary Table:

| Furnace Type | Primary Application | Key Characteristic |

|---|---|---|

| Electric Arc Furnace (EAF) | Large-scale steel production (melting scrap) | High-volume melting, intense heat from electric arcs |

| Induction Furnace | Clean melting and alloying of various metals | Minimal melt loss, electromagnetic heating, little refining |

| Vacuum Furnace | High-purity heat treatment (e.g., brazing, sintering) | Controlled, non-contaminating atmosphere, precise temperature |

Ready to Optimize Your Metal Processing?

Choosing the right furnace is critical for achieving your desired material properties, whether you're melting, alloying, or heat-treating. KINTEK specializes in high-performance lab equipment, including furnaces designed for precision and reliability in metallurgical applications.

We can help you select the ideal equipment to enhance your process efficiency, ensure product purity, and guarantee repeatable results. Let our experts guide you to the perfect solution for your laboratory's specific needs.

Contact KINTEK today to discuss your requirements and discover how our solutions can advance your work!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- What is the process of thin film deposition by sputtering? A Step-by-Step Guide to Atomic-Level Coating

- What are the configurations of a filter press? Recessed Chamber vs. Membrane Explained

- Can all plastics be used in pyrolysis? Choose the Right Feedstock for Optimal Results

- Why is a 24-hour slow furnace cooling process necessary after annealing? Ensure Ceramic Integrity and Data Stability

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- What are the different deposition techniques? A Guide to PVD, CVD, ALD, and More

- Does pyrolysis produce pollution? Understanding the Environmental Impact of Modern Waste Conversion

- What are zeolites advantages and disadvantages? Maximize Molecular Selectivity and Efficiency