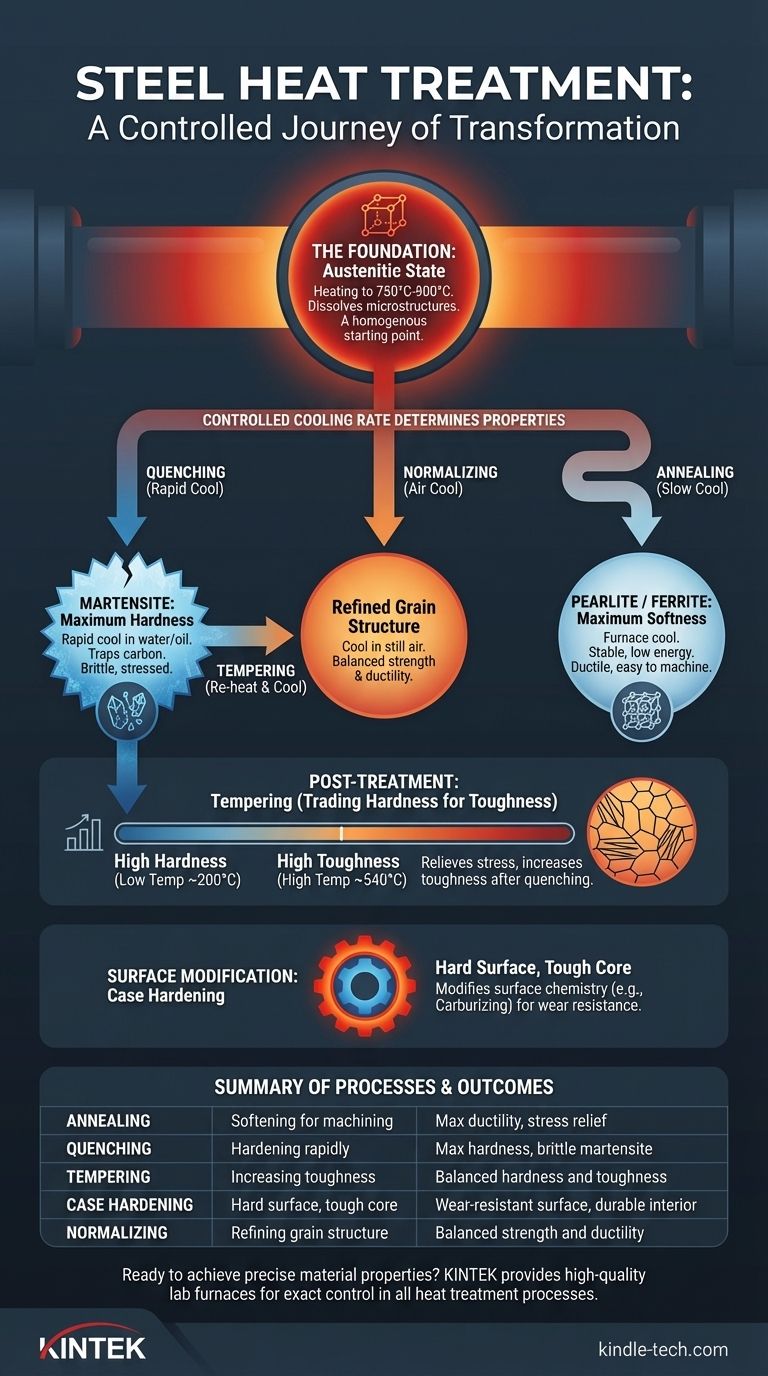

At its core, heat treatment is a highly controlled process of heating and cooling steel to deliberately change its internal microscopic structure. The primary processes include annealing for softening, quenching for hardening, tempering to increase toughness, and case hardening to create a wear-resistant surface. Each of these procedures is designed to manipulate the steel's crystal structure to achieve a specific set of mechanical properties.

The fundamental principle of steel heat treatment is not about a single process, but about a controlled sequence of heating, holding, and cooling. This sequence manipulates the steel's microstructure to predictably trade properties like hardness, toughness, and ductility to meet a specific engineering requirement.

The Foundation: Transforming the Steel's Structure

Before any specific outcome can be achieved, the steel must be brought to a uniform, workable state. This initial heating phase is the foundation for all subsequent treatments.

The Austenitic State

Nearly all common heat treatments for steel begin by heating the metal to a critical temperature, typically between 750°C and 900°C (1382°F and 1652°F), depending on the alloy.

At this temperature, the steel's internal crystal structure transforms into a state called austenite. Austenite has a unique ability to dissolve large amounts of carbon, creating a uniform, solid solution.

Why This Step is Critical

Creating a fully austenitic structure is like hitting a reset button. It dissolves the existing microstructures within the steel, creating a homogenous starting point from which all other desired structures—hard, soft, or tough—can be formed through controlled cooling.

Primary Hardening and Softening Processes

The rate at which the steel is cooled from its austenitic state is the single most important factor in determining its final properties.

Quenching: For Maximum Hardness

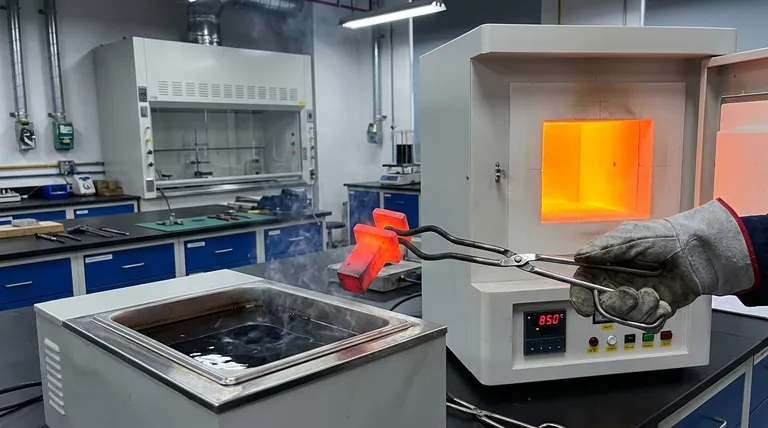

Quenching is the process of cooling the steel extremely rapidly from its austenitic state. This is typically done by plunging the hot steel into a liquid like water, brine, or oil.

This rapid cooling traps the dissolved carbon atoms, forcing the formation of a very hard, brittle, and stress-filled microstructure known as martensite. A quenched part is at its maximum potential hardness but is often too brittle for practical use.

Annealing: For Maximum Softness

Annealing is the exact opposite of quenching. It involves cooling the steel very slowly from the austenite temperature, often by leaving it inside the furnace and letting it cool down over many hours.

This slow cooling allows the crystal structure to re-form in the most stable, low-energy state, typically pearlite or ferrite. The result is a steel that is very soft, highly ductile, and free of internal stresses, making it easy to machine or form.

Normalizing: A Balance of Strength and Ductility

Normalizing sits between annealing and quenching. The steel is heated to the austenitic range and then cooled in still air at room temperature.

The cooling rate is faster than annealing but much slower than quenching. This process refines the grain structure and produces a steel that is stronger and harder than an annealed steel but more ductile than a quenched steel.

Refining the Properties: Post-Treatment Adjustments

A part that has only been quenched is rarely useful. Subsequent treatments are almost always required to refine its properties for a real-world application.

Tempering: Trading Hardness for Toughness

Tempering is a low-temperature heat treatment applied after quenching. The hardened, brittle part is re-heated to a precise temperature, held for a specific time, and then cooled.

This process relieves the internal stresses created during quenching and allows some of the brittle martensite to transform. The primary result is a significant increase in toughness (resistance to fracture) at the expense of some hardness.

The Tempering Temperature Spectrum

The final properties are directly controlled by the tempering temperature. A low-temperature temper (around 200°C / 400°F) will retain high hardness, while a high-temperature temper (around 540°C / 1000°F) will sacrifice more hardness to gain significant toughness and ductility.

Modifying the Surface: Case Hardening

Sometimes, you need a component with two different sets of properties: a very hard, wear-resistant surface and a softer, tougher core that can absorb shock. This is achieved through case hardening.

The Core Principle: Hard Surface, Tough Core

Case hardening refers to a group of processes that modify the chemistry of the steel's surface layer. This allows the surface to be hardened by quenching while the core of the part remains relatively soft and tough.

Carburizing: Adding Carbon

Carburizing is one of the most common methods of case hardening. The component, typically made of low-carbon steel, is heated in a carbon-rich atmosphere. Carbon atoms diffuse into the surface of the part.

After carburizing, the part has a high-carbon "case" and a low-carbon "core." The entire part can then be quenched and tempered. The high-carbon surface becomes extremely hard, while the low-carbon core becomes tough and ductile.

Understanding the Trade-offs

Heat treatment is not a magic bullet; it is a series of calculated compromises designed to achieve a specific performance target.

The Hardness vs. Toughness Dilemma

The most fundamental trade-off in steel heat treatment is between hardness and toughness. You cannot maximize both. Increasing hardness through quenching inherently increases brittleness. Restoring toughness through tempering inherently reduces hardness. The goal is to find the optimal balance for the application.

The Risk of Distortion and Cracking

Rapid cooling from high temperatures introduces immense internal stress. Quenching can cause thin sections to cool faster than thick sections, leading to part distortion (warping) or even cracking. Proper process control and part design are critical to mitigating these risks.

Process Control is Everything

The final properties of a heat-treated part are dictated by three variables: temperature, time, and cooling rate. Small deviations in any of these can lead to dramatically different results. This is why heat treatment is a precise science, not a casual operation.

Choosing the Right Process for Your Goal

Your choice of heat treatment process should be driven directly by the primary performance requirement of the component.

- If your primary focus is maximum hardness and wear resistance (e.g., a file or cutting edge): The correct path is to quench and follow with a very low-temperature temper.

- If your primary focus is maximum toughness and impact resistance (e.g., a structural bolt or a spring): The correct path is to quench and follow with a high-temperature temper.

- If your primary focus is preparing a part for extensive machining: The correct path is to perform a full anneal to make the material as soft and stress-free as possible.

- If your primary focus is a wear-resistant surface with a durable core (e.g., a gear or bearing): The correct path is a case hardening process like carburizing, followed by quenching and tempering.

By understanding these fundamental processes, you can specify the precise material properties your application demands.

Summary Table:

| Process | Primary Goal | Key Outcome |

|---|---|---|

| Annealing | Soften steel for machining | Maximum ductility, stress relief |

| Quenching | Harden steel rapidly | Maximum hardness, brittle martensite |

| Tempering | Increase toughness after quenching | Balanced hardness and toughness |

| Case Hardening | Create hard surface, tough core | Wear-resistant surface, durable interior |

| Normalizing | Refine grain structure | Balanced strength and ductility |

Ready to achieve precise material properties in your lab? The right heat treatment process is critical for your steel components' performance. KINTEK specializes in providing the high-quality lab furnaces and equipment needed for exact temperature control and consistent results in annealing, quenching, tempering, and case hardening processes. Let our experts help you select the perfect solution for your laboratory's specific needs. Contact us today to discuss how we can support your heat treatment applications!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the difference between a muffle furnace and a normal furnace? Ensuring Sample Purity with Indirect Heating

- What are the safety precautions for heat experiment? Essential Steps to Prevent Lab Burns and Accidents

- What is the cooling rate of a muffle furnace? Understanding Its Slow, Passive Nature

- How is the ash content determined in a muffle furnace? Master the Gravimetric Analysis Method

- What is the function of the sintering process in ceramic manufacturing? Achieve High Density and Structural Integrity