While lauded for their superior heat and mass transfer, fluidized bed reactors (FBRs) are not a universal solution and come with significant operational limitations. The primary drawbacks stem from their complex fluid dynamics, leading to challenges such as the erosion of internal components, the loss of fine particles, and higher energy costs associated with the fluidizing gas.

The core strength of a fluidized bed reactor—its ability to make solid particles behave like a turbulent fluid—is simultaneously the source of its most significant limitations. Managing these inherent physical behaviors is the central challenge in designing and operating an FBR.

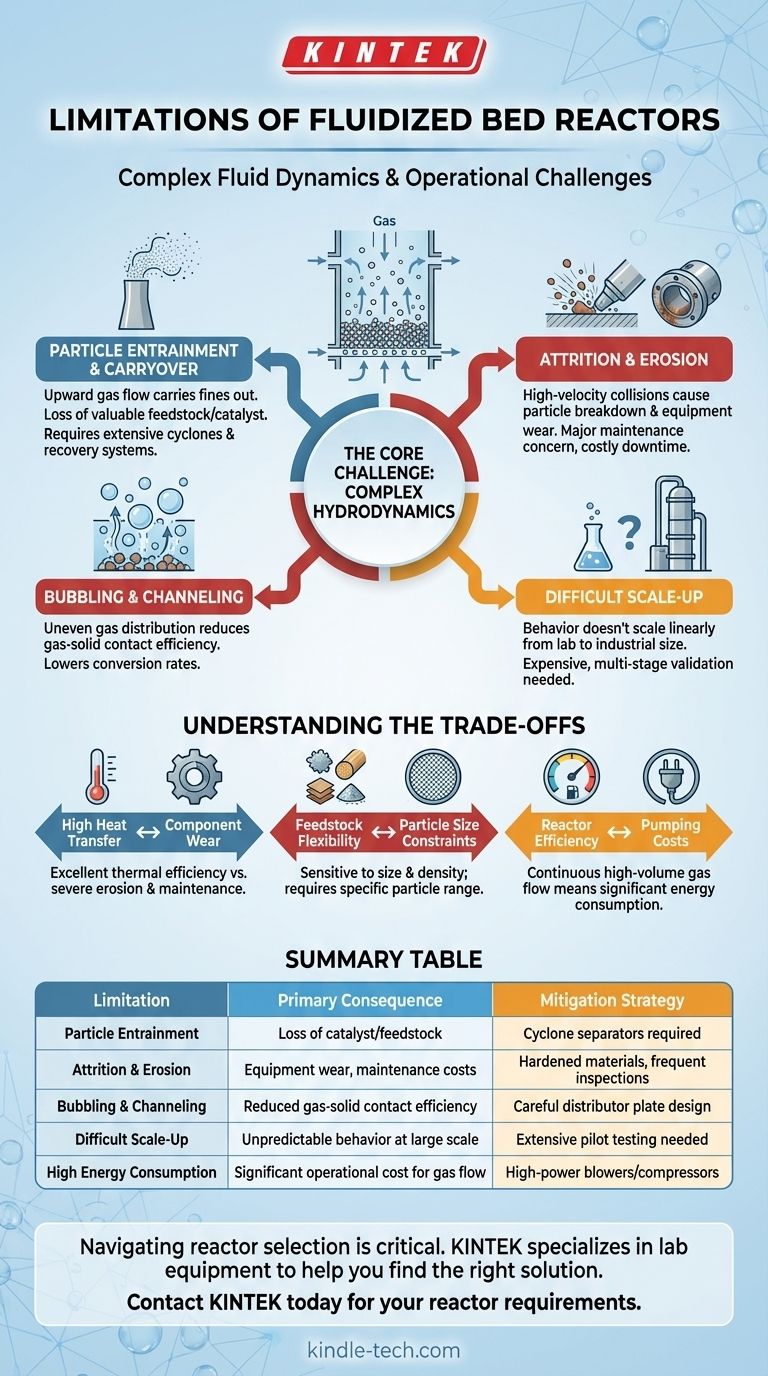

The Core Challenge: Complex Hydrodynamics

The turbulent, mixed nature of a fluidized bed creates a demanding operational environment. Unlike a simple packed bed where particles are static, the constant motion in an FBR introduces several potential failure points and inefficiencies.

Particle Entrainment and Carryover

The upward flow of the fluidizing gas can easily carry fine particles out of the reactor bed. This phenomenon, known as entrainment or carryover, results in the loss of valuable feedstock or catalyst.

To manage this, FBR systems require extensive downstream equipment, typically one or more cyclones, to separate and recover these entrained particles, adding significant capital cost and complexity.

Attrition and Erosion

The constant, high-velocity collisions between particles and between particles and the reactor walls cause two distinct problems. Attrition is the process where the particles themselves break down into smaller fines, worsening the entrainment issue.

Erosion is the mechanical wear of the reactor's internal components, heat transfer tubes, and downstream piping. This is a major maintenance concern that can lead to costly downtime and requires the use of specialized, hardened materials.

Bubbling and Channeling

The fluidizing gas does not always distribute evenly throughout the solid bed. It can coalesce into large bubbles that rise rapidly through the bed, effectively bypassing the solid particles.

This bubbling or channeling dramatically reduces the contact efficiency between the gas and the solids, undermining the reactor's primary purpose and lowering conversion rates. Preventing this requires careful distributor plate design and operational control.

Difficult Scale-Up

The fluid dynamic behavior of an FBR does not scale in a simple, linear fashion. A design that works perfectly in a small laboratory or pilot reactor may exhibit completely different and unpredictable bubbling or channeling behavior at an industrial scale.

This makes scaling up an FBR a complex and expensive process, often requiring multiple intermediate pilot stages to validate the design and mitigate risk.

Understanding the Trade-offs

Choosing an FBR involves accepting a series of compromises. The advantages you gain in one area often create direct challenges in another.

High Heat Transfer vs. Component Wear

The very particle motion that guarantees excellent heat transfer and a uniform temperature profile throughout the reactor is the same motion that causes severe erosion. You are trading operational simplicity and component longevity for thermal efficiency.

Feedstock Flexibility vs. Particle Size Constraints

While FBRs can be adapted for various feedstocks like biomass or plastics, they are sensitive to particle size and density. Particles must be within a specific range to fluidize properly. If they are too large or dense, they won't lift; if they are too small or light, they will be immediately carried out of the reactor.

Reactor Efficiency vs. Pumping Costs

Maintaining the fluidization state requires a continuous, high-volume flow of gas, which must be driven by powerful blowers or compressors. This translates directly to significant and continuous energy consumption, representing a major component of the reactor's operational cost.

Is an FBR Right for Your Application?

Your decision must be based on a clear-eyed assessment of your primary technical and economic goals.

- If your primary focus is maximizing heat and mass transfer for a highly exothermic or endothermic reaction: An FBR is a strong candidate, but you must budget for robust particle separation systems (cyclones) and erosion-resistant materials.

- If your primary focus is minimizing operational complexity and maintenance costs: A packed bed or moving bed reactor might be a more suitable choice, as they avoid the challenges of fluidization, albeit with lower heat transfer rates.

- If you are working with a feedstock that has a wide or inconsistent particle size distribution: You must plan for significant feedstock preparation (e.g., grinding and sieving) or consider an alternative reactor type that is more forgiving of size variations.

Understanding these limitations allows you to properly design, budget for, and operate a fluidized bed system, harnessing its power while mitigating its inherent risks.

Summary Table:

| Limitation | Primary Consequence | Mitigation Strategy |

|---|---|---|

| Particle Entrainment | Loss of catalyst/feedstock | Cyclone separators required |

| Attrition & Erosion | Equipment wear, maintenance costs | Hardened materials, frequent inspections |

| Bubbling & Channeling | Reduced gas-solid contact efficiency | Careful distributor plate design |

| Difficult Scale-Up | Unpredictable behavior at large scale | Extensive pilot testing needed |

| High Energy Consumption | Significant operational cost for gas flow | High-power blowers/compressors |

Navigating the complexities of reactor selection is critical for your lab's success. The challenges of particle entrainment, erosion, and scale-up highlighted for fluidized bed reactors require expert guidance and reliable equipment.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our team can help you select the right reactor system for your specific application, ensuring optimal performance and efficiency. Let us provide the durable, high-performance equipment your research demands.

Contact KINTEK today to discuss your reactor requirements and find a robust solution for your laboratory.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- What is the purpose of using a high-temperature hydrothermal reactor? Enhance Iodine@Activated Carbon Cathode Synthesis

- What role does an autoclave play in simulating PWR conditions? Advanced Material Validation for Nuclear Safety

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?