While incredibly versatile for creating large-radius curves, roll bending is not a universal solution for all metal forming needs. The process is fundamentally limited by the geometry of the rollers, which results in unbent sections at the start and end of the workpiece. Furthermore, it struggles to achieve tight radii, maintain precise tolerances, and prevent material distortion without significant operator skill and specialized equipment.

The core limitation of roll bending stems from its "freeform" nature. While this allows for the efficient creation of large, sweeping curves, it provides less constraint than other methods, making it difficult to control precision, tight radii, and the geometry at the very ends of the material.

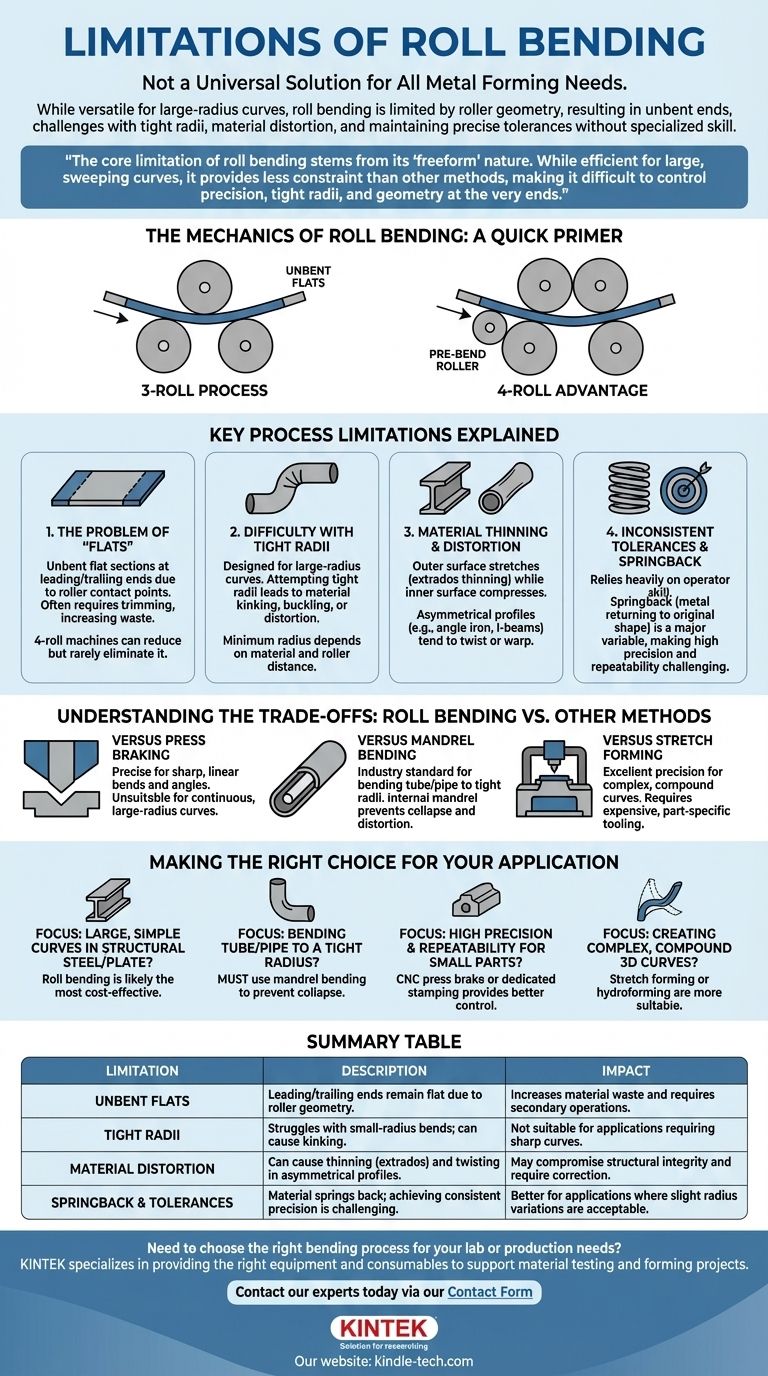

The Mechanics of Roll Bending: A Quick Primer

To understand the limitations, you must first understand the process. Roll bending uses a series of three or four rollers to progressively curve a metal bar, plate, or structural shape.

The 3-Roll Process

In a typical 3-roll system, two lower rollers support the material while a top roller is pressed down, inducing a bend. As the material is fed through the rollers, this pressure point creates a continuous, gradual curve.

The 4-Roll Advantage

A 4-roll machine adds a fourth roller that can pre-bend the leading edge of the material before the main rolling process begins. This helps mitigate one of the key limitations of the 3-roll system, but it does not eliminate it entirely.

Key Process Limitations Explained

Each limitation of roll bending is a direct consequence of its mechanics. Understanding these will help you determine if it's the correct process for your project.

The Problem of "Flats"

The most significant limitation is the creation of unbent flat sections at the leading and trailing ends of the workpiece. Because the material must pass between at least two roller contact points to initiate a bend, the first and last few inches cannot be properly curved.

These flats often need to be trimmed off as scrap, increasing material waste and labor costs. While 4-roll machines or a secondary pre-bending operation can reduce this effect, they rarely eliminate it completely.

Difficulty with Tight Radii

Roll bending is inherently designed for large-radius curves. The minimum achievable radius is a function of the material's properties, its cross-section, and the distance between the rollers on the machine.

Attempting to form a radius that is too tight for the process can lead to material kinking, buckling, or profile distortion. For tight bends, especially in tube or pipe, processes like mandrel bending are superior.

Material Thinning and Distortion

As the material bends, the outer surface is stretched and becomes thinner, while the inner surface is compressed. This effect, known as extrados thinning, can be a critical failure point in high-pressure or structural applications.

Furthermore, asymmetrical profiles like angle iron or I-beams have a tendency to twist or warp during rolling because their resistance to bending is not uniform. Correcting this requires specialized tooling and expert operator intervention.

Inconsistent Tolerances and Springback

Roll bending is more of an art than a science, relying heavily on operator experience. Springback, the tendency of metal to partially return to its original shape after bending, is a major variable.

Achieving highly precise, repeatable tolerances from part to part is challenging. The process is better suited for applications where slight variations in the final radius are acceptable, such as architectural structures or large tank shells.

Understanding the Trade-offs: Roll Bending vs. Other Methods

Choosing the right bending method requires comparing their strengths and weaknesses for your specific goal.

Versus Press Braking

A press brake uses a punch and die to create sharp, linear bends. It is extremely precise for angles but completely unsuited for creating a continuous, large-radius curve. It is a complementary process, not a direct competitor.

Versus Mandrel Bending

For bending tube and pipe to a tight radius, mandrel bending is the industry standard. It uses an internal mandrel to support the inside of the tube, preventing the collapse and distortion that would occur during roll bending.

Versus Stretch Forming

Stretch forming grips the material at both ends, stretches it to its yield point, and then wraps it around a forming die. It offers excellent precision and is ideal for creating complex, compound curves (curved in two directions) on large sheets, but it requires expensive, part-specific tooling.

Making the Right Choice for Your Application

Use these guidelines to determine if roll bending fits your project's primary requirements.

- If your primary focus is creating large, simple curves in structural steel or plate: Roll bending is likely the most cost-effective and efficient method available.

- If your primary focus is bending tube or pipe to a tight radius: You must use mandrel bending to prevent the material from collapsing.

- If your primary focus is high precision and repeatability for smaller parts: A CNC press brake or a dedicated stamping process will provide better control.

- If your primary focus is creating complex, compound 3D curves: Stretch forming or hydroforming are more suitable, though they come with higher tooling costs.

Ultimately, selecting the correct manufacturing process requires aligning the method's capabilities with your project's non-negotiable design constraints.

Summary Table:

| Limitation | Description | Impact |

|---|---|---|

| Unbent Flats | Leading/trailing ends remain flat due to roller geometry. | Increases material waste and requires secondary operations. |

| Tight Radii | Struggles with small-radius bends; can cause kinking. | Not suitable for applications requiring sharp curves. |

| Material Distortion | Can cause thinning (extrados) and twisting in asymmetrical profiles. | May compromise structural integrity and require correction. |

| Springback & Tolerances | Material springs back; achieving consistent precision is challenging. | Better for applications where slight radius variations are acceptable. |

Need to choose the right bending process for your lab or production needs?

At KINTEK, we specialize in providing the right lab equipment and consumables to support your material testing and forming projects. Whether you're evaluating material behavior or selecting the optimal manufacturing process, our expertise can help you avoid costly mistakes and achieve superior results.

Contact our experts today via our Contact Form to discuss how we can support your laboratory and production challenges with precision equipment and tailored solutions.

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Three-dimensional electromagnetic sieving instrument

- Powerful Plastic Crusher Machine

- Double Plate Heating Press Mold for Lab

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

People Also Ask

- How should a sample be installed onto the sample holder? Ensure Mechanical Stability & Electrical Integrity

- What is a hot mounting press machine? Precision Control for Metallurgy & Electronics Assembly

- What are the advantages of an electrolytic polishing device for EK-181 steel TEM samples? Ensure Peak Sample Integrity

- What role do laboratory grinding and polishing systems play in nitriding? Ensure Superior Mirror-Finish & Ion Penetration

- What is the general procedure and what precautions should be taken during the polishing process? Achieve a Flawless Electrode Finish