At its core, vacuum sintering offers three primary advantages: it prevents chemical contamination from the atmosphere, allows for precise control over the entire process, and results in a final product with superior density, purity, and mechanical properties. By removing reactive gases like oxygen and nitrogen, the process enables materials to bond at an atomic level without the formation of unwanted oxides or nitrides, which can compromise the integrity of the component.

The fundamental value of vacuum sintering is its ability to create an ultra-clean environment. This prevents unwanted chemical reactions, allowing for the formation of denser, purer, and stronger parts than can typically be achieved with atmosphere-based sintering methods.

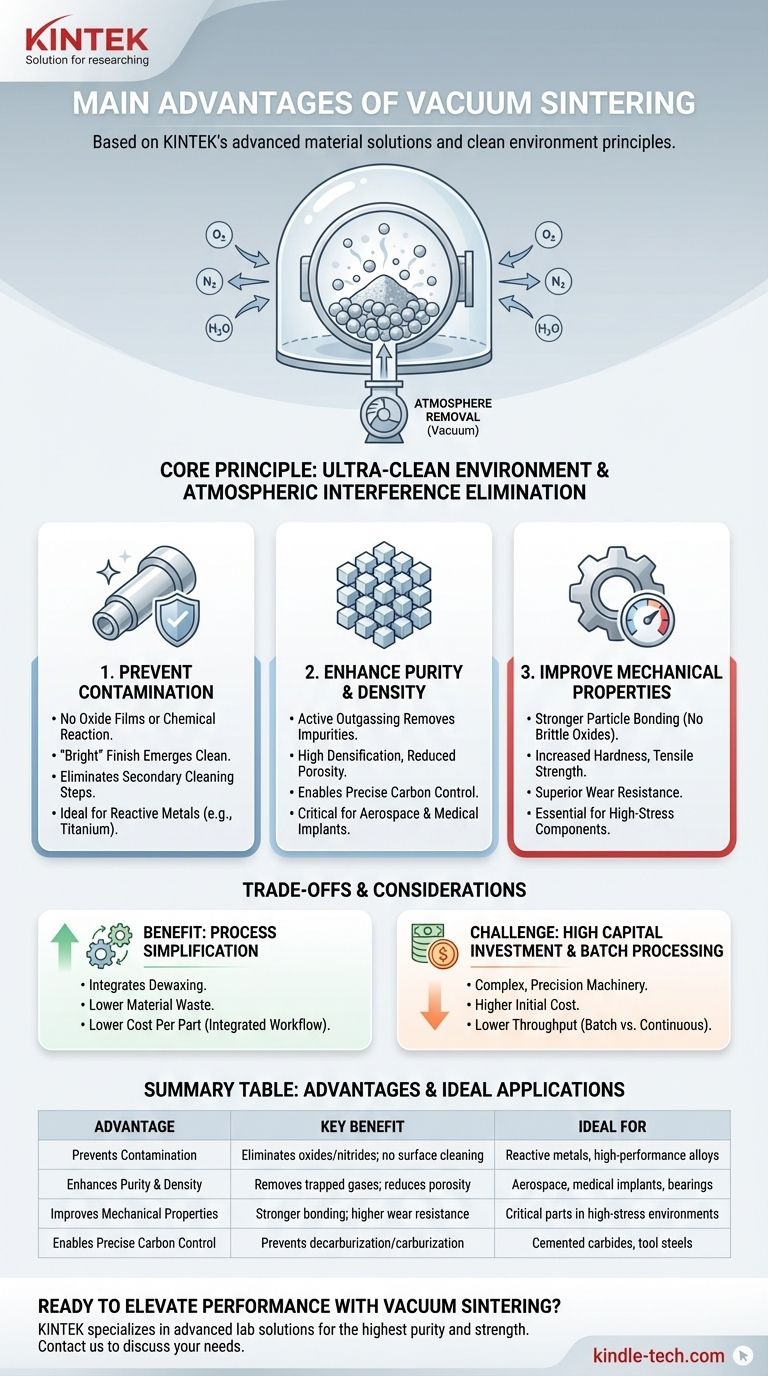

The Core Principle: Eliminating Atmospheric Interference

The defining feature of vacuum sintering is the removal of the surrounding atmosphere. This simple act has profound implications for the material at every stage of the process.

Preventing Oxidation and Contamination

By operating under a vacuum, the furnace actively removes reactive gases like oxygen, nitrogen, and water vapor. This prevents the formation of oxide films on the powder particles.

The direct result is a component that emerges from the furnace clean and "bright," often eliminating the need for secondary cleaning or surface finishing operations.

Enhancing Material Purity

The vacuum environment does more than just prevent new contamination; it actively purifies the material. It helps pull out adsorbed gases and other volatile impurities trapped within the raw material powder.

This outgassing process leads to a final alloy of significantly higher purity, which is critical for high-performance applications.

Enabling Precise Carbon Control

For carbon-sensitive alloys like cemented carbides, the vacuum environment provides exceptional control. It prevents both decarburization (loss of carbon) and unwanted carburization (gain of carbon).

This level of control ensures the final material has the exact carbon content required for its specified hardness and performance characteristics.

Achieving Superior Material Properties

The clean, controlled environment of a vacuum furnace directly translates to measurable improvements in the physical and mechanical properties of the sintered part.

Promoting High Densification

In traditional sintering, air trapped in the pores between powder particles can inhibit the material's ability to fully consolidate. A vacuum removes this trapped gas.

This allows atomic diffusion to occur more effectively, closing the pores and resulting in a final product with higher density and significantly reduced porosity.

Improving Strength and Wear Resistance

The combination of high purity and high density creates a stronger component. With no brittle oxide layers at the grain boundaries, the bond between particles is stronger.

This enhanced internal structure leads to superior mechanical properties, including increased hardness, tensile strength, and wear resistance, which are critical for components in high-stress machinery.

Enhancing Particle Bonding

By removing the oxide films from particle surfaces before the material reaches its sintering temperature, the vacuum improves the wettability between different phases of the alloy.

This means a liquid phase, if present, can flow more freely and bond the solid particles more effectively, leading to a stronger and more homogenous final structure.

Understanding the Trade-offs and Practical Realities

While the advantages are significant, choosing vacuum sintering requires a clear understanding of its economic and operational context. It is not a universal solution.

The Benefit: Process Simplification and Lower Waste

Vacuum sintering can simplify the overall manufacturing workflow. Processes like dewaxing (burning off lubricants) can often be integrated into a single furnace cycle.

This integration, combined with the elimination of post-sintering cleaning steps and minimal material waste, can lead to a lower cost per part despite the high-tech nature of the equipment.

The Challenge: High Capital Investment

Vacuum furnaces are complex, precision machines. The initial capital expenditure for the furnace, vacuum pumps, and control systems is significantly higher than for conventional atmosphere furnaces.

This technology represents a substantial investment that must be justified by the need for superior part quality or the processing of specialized materials.

The Limitation: Batch Processing and Material Suitability

Most vacuum sintering is a batch process, meaning parts are loaded, the cycle is run, and the parts are unloaded. This can have lower throughput than continuous atmosphere furnaces.

Furthermore, while ideal for reactive and refractory metals, cemented carbides, and certain ceramics, it may be overkill or unsuitable for simple ferrous powder metal parts where atmosphere sintering is more cost-effective.

Making the Right Choice for Your Application

Selecting the right sintering method depends entirely on the performance requirements and cost constraints of your final component.

- If your primary focus is maximum purity and performance: Vacuum sintering is the definitive choice for reactive materials like titanium, refractory metals, and high-performance alloys where any contamination would be catastrophic.

- If your primary focus is superior mechanical strength: For critical components like aerospace turbine blades, automotive bearings, or medical implants, the high density and structural integrity from vacuum sintering are non-negotiable.

- If your primary focus is cost-effective production of simple parts: Traditional atmosphere sintering is likely a more economical solution for high-volume, less-demanding components made from common iron-based powders.

Ultimately, adopting vacuum sintering is a decision to prioritize material quality and performance above all else.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Prevents Contamination | Eliminates oxides/nitrides; no surface cleaning needed | Reactive metals (titanium), high-performance alloys |

| Enhances Purity & Density | Removes trapped gases/impurities; reduces porosity | Aerospace components, medical implants, bearings |

| Improves Mechanical Properties | Stronger particle bonding; higher wear resistance | Critical parts in high-stress environments |

| Enables Precise Carbon Control | Prevents decarburization/carburization in alloys | Cemented carbides, tool steels |

Ready to elevate your material performance with vacuum sintering? KINTEK specializes in advanced lab equipment and consumables, providing solutions for laboratories that demand the highest purity and strength in their sintered components. Whether you're working with reactive metals, ceramics, or high-performance alloys, our expertise ensures you achieve superior results. Contact us today to discuss how our vacuum sintering solutions can meet your specific needs!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What are the advantages of a vacuum hot pressing furnace? Achieve high-density NTC ceramics with superior stability.

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- How does a vacuum environment system contribute to the hot pressing sintering of B4C-CeB6? Unlock Peak Ceramic Density

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What are the advantages of vacuum sintering? Achieve Superior Purity, Strength, and Performance