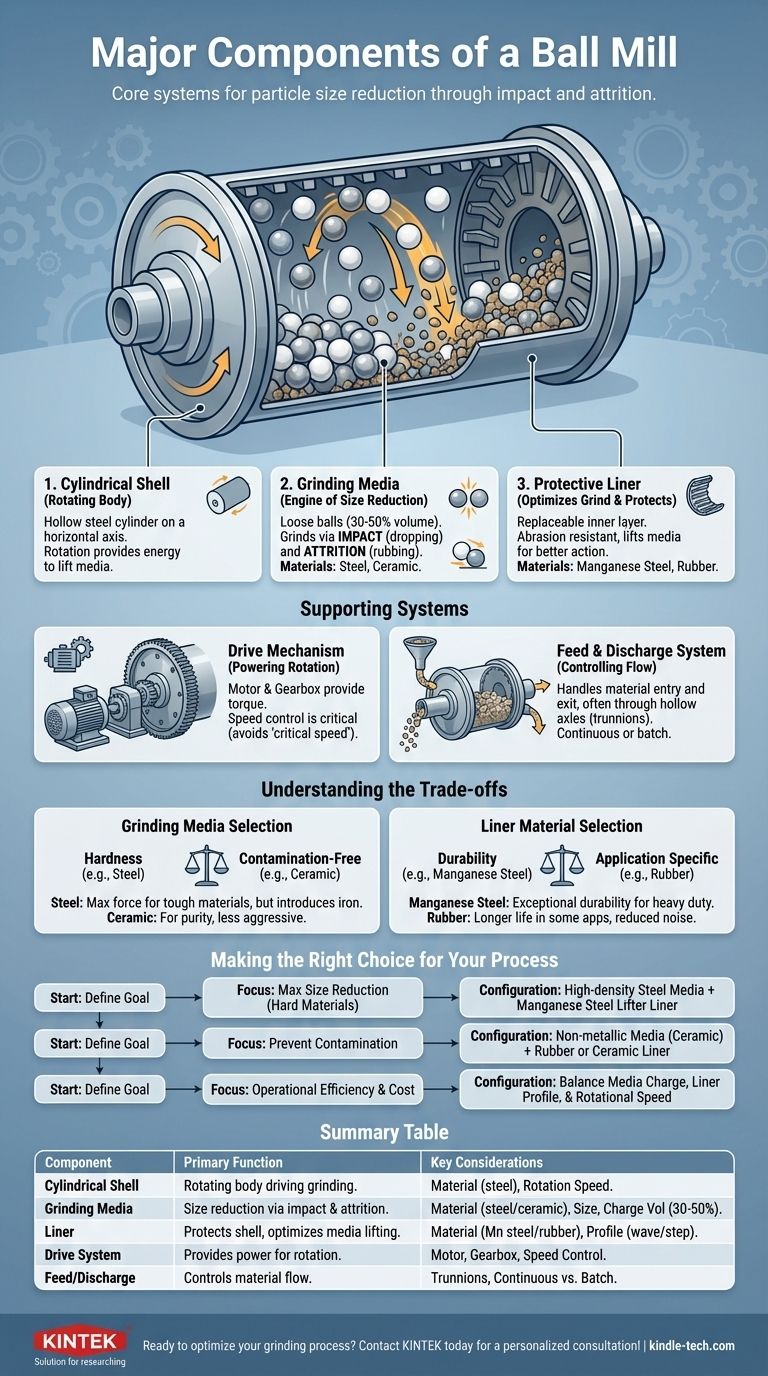

At its core, a ball mill achieves particle size reduction through a few key components working in a simple but powerful system. The three primary components are the rotating cylindrical shell, the grinding media (balls) contained within it, and the protective liner on the shell's inner surface. The rotation of the shell lifts the media, which then tumbles and falls, grinding the material through the forces of impact and attrition.

Understanding a ball mill is not just about identifying its parts. It is about recognizing how the material, size, and interaction of these components are precisely controlled to achieve a specific grinding objective.

The Core Components and Their Function

A ball mill's effectiveness is born from the interplay between its main structural and functional parts. Each is selected to withstand extreme forces and perform a specific role in the grinding process.

The Cylindrical Shell: The Rotating Body

The shell is the main body of the mill. It is a hollow cylinder, typically made of steel, that rotates on a horizontal or slightly inclined axis.

This rotation is the driving force of the entire process. It provides the energy needed to lift the grinding media and create the tumbling motion essential for size reduction.

Grinding Media: The Engine of Size Reduction

The grinding media are the loose balls placed inside the shell, typically occupying 30% to 50% of the internal volume. These are the tools that perform the actual grinding.

As the shell rotates, the media are lifted up the side before cascading and tumbling back down. This action crushes and grinds the target material through two primary mechanisms:

- Impact: When balls drop from near the top of the rotation, striking the material below.

- Attrition: When balls rub against each other and the material as they slide and roll.

The media are made from various materials, such as high-carbon steel, stainless steel, or ceramics, depending on the grinding requirements and contamination sensitivity.

The Liner: Protecting the Shell and Optimizing the Grind

The liner is a critical, replaceable layer fixed to the inner surface of the shell. It serves two essential purposes.

First, it protects the shell from the intense abrasion caused by the tumbling media and the material being ground. Liners are made of highly abrasion-resistant materials like manganese steel or specialized rubber.

Second, the liner's profile is designed to help lift the grinding media. Different shapes (e.g., wave or step-lifters) improve the efficiency of the tumbling action, preventing slippage and ensuring the media are lifted effectively for maximum impact.

The Supporting Systems

While not part of the core grinding action, the drive and material handling systems are essential for the mill's operation.

The Drive Mechanism: Powering the Rotation

A powerful electric motor and gearbox assembly provides the torque needed to rotate the heavy, loaded shell.

The speed of rotation is a critical operating parameter. It must be carefully controlled to achieve a cascading motion. If the speed is too high (reaching the "critical speed"), the media will be held against the shell by centrifugal force, and grinding will cease.

Feed and Discharge System: Controlling the Flow

Material must be able to enter and exit the mill. This is handled by the feed and discharge systems, which are often integrated into the hollow axles (or trunnions) on which the mill rotates.

In a continuous system, the material is fed into one end and gradually flows to the other as it is ground, exiting once it reaches the desired fineness.

Understanding the Trade-offs

The selection of each component involves balancing performance, cost, and the specific requirements of the final product.

Grinding Media: Hardness vs. Contamination

The choice of media is a fundamental trade-off. Hardened steel balls provide maximum grinding force and are ideal for tough, abrasive materials. However, they will inevitably introduce slight iron contamination into the product.

For applications where purity is paramount, such as in pharmaceuticals or certain ceramics, ceramic media (like alumina or zirconia) are used. These prevent metallic contamination but may not grind as aggressively and can be more brittle.

Liner Material: Durability vs. Application

Manganese steel liners offer exceptional durability and impact resistance, making them the standard for heavy-duty mineral grinding. They are, however, a significant cost factor.

Rubber liners can offer a longer wear life in specific applications, reduce noise levels, and are often preferred when grinding with steel media to optimize the lifting action and reduce liner wear. However, they have temperature and chemical compatibility limitations.

Making the Right Choice for Your Process

Your specific goal dictates the optimal configuration of your ball mill's components.

- If your primary focus is maximum size reduction of hard materials: You will likely require high-density steel media paired with a durable manganese steel lifter-bar liner to maximize impact forces.

- If your primary focus is preventing product contamination: You must use non-metallic media, such as ceramic balls, and consider a rubber or even ceramic liner.

- If your primary focus is operational efficiency and cost: You must carefully balance media charge level, liner profile, and rotational speed to minimize energy consumption and wear per ton of material processed.

By understanding how these components function together, you can configure the ball mill from a simple grinder into a precision tool for your material processing needs.

Summary Table:

| Component | Primary Function | Key Considerations |

|---|---|---|

| Cylindrical Shell | Rotating body that drives the grinding action. | Material (steel), rotation speed. |

| Grinding Media | Performs size reduction via impact and attrition. | Material (steel, ceramic), size, charge volume (30-50%). |

| Liner | Protects the shell and optimizes media lifting. | Material (manganese steel, rubber), profile (wave, step). |

| Drive System | Provides power to rotate the shell. | Motor, gearbox, speed control. |

| Feed/Discharge | Controls material flow into and out of the mill. | Trunnions, continuous vs. batch operation. |

Ready to optimize your grinding process? The right ball mill configuration is critical for achieving your desired particle size, purity, and operational efficiency. At KINTEK, we specialize in providing high-quality lab equipment, including ball mills and consumables tailored to your specific needs—whether you require maximum durability, contamination-free grinding, or energy efficiency. Let our experts help you select the perfect setup. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- How do you calculate ball mill load? Optimize Grinding Efficiency and Reduce Costs

- Why is secondary ball milling necessary for LATP? Enhance Sintering Activity & Ionic Conductivity

- What role does a planetary ball mill play in the synthesis of Li6PS5Br? Revolutionize Solid-State Electrolyte Production

- What role does a planetary ball mill play in the preparation of LGVO powders? Precision Refinement for Aerosol Deposition

- What role does a high-energy planetary ball mill play in the preparation of Ni-SmDC catalyst powders? Essential Refinement

- How do you remove powder from a ball mill? A Step-by-Step Guide to Safe & Efficient Material Recovery

- What is the difference between a planetary mill and a ball mill? Discover the Key to High-Energy Grinding

- What is the function of a high-energy ball mill in NiCr composites? Optimize Synthesis with Mechanical Activation