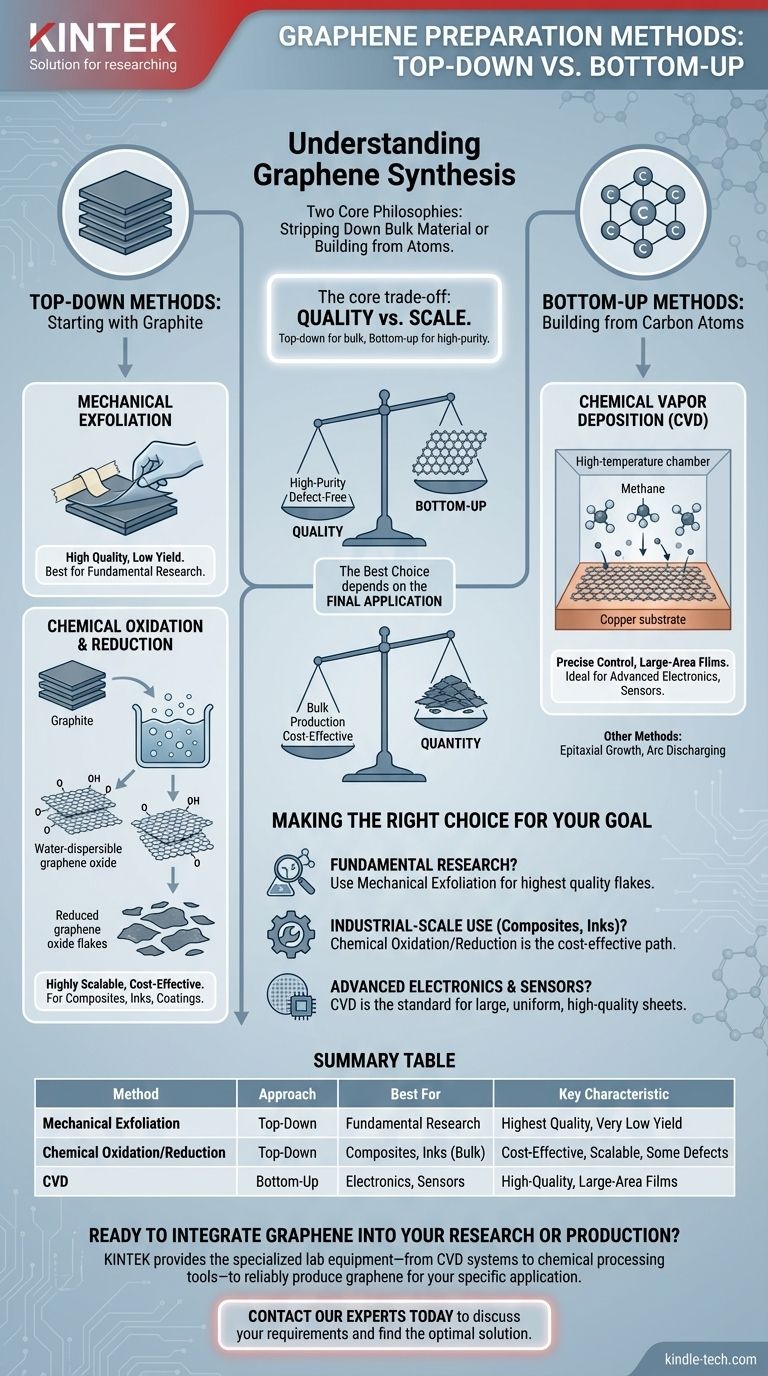

At its core, graphene preparation involves two distinct approaches. These methods are categorized as either top-down, where graphene is derived from bulk graphite, or bottom-up, where it is constructed atom-by-atom from carbon sources. Each category contains several specific techniques tailored for different applications, scales, and quality requirements.

The central decision in graphene synthesis is a trade-off between quality and scale. Top-down methods are excellent for producing large quantities of graphene flakes for bulk applications, while bottom-up methods are superior for creating high-purity, continuous graphene sheets required for advanced electronics.

The Two Core Philosophies of Graphene Synthesis

Understanding the fundamental difference between starting big (top-down) and starting small (bottom-up) is the first step in navigating graphene production.

Top-Down Methods: Starting with Graphite

The top-down approach is conceptually simple: you begin with graphite, which is essentially a stack of countless graphene layers, and find a way to separate those layers.

These methods are often suited for producing large volumes of graphene flakes, which can then be dispersed in other materials.

Examples include mechanical exfoliation and chemical oxidation-reduction.

Bottom-Up Methods: Building from Carbon Atoms

The bottom-up approach involves assembling the graphene lattice from individual carbon atoms or small molecules.

This method offers precise control over the structure and quality of the final product, making it ideal for creating high-performance, uniform sheets.

The most prominent example is Chemical Vapor Deposition (CVD), but others include epitaxial growth and arc discharging.

A Deeper Look at Key Production Methods

While many variations exist, a few key techniques dominate both research and industrial production. Each serves a distinct purpose.

Mechanical Exfoliation (Top-Down)

This is the original method used to first isolate graphene, famously using adhesive tape to peel layers from a piece of graphite.

It produces extremely high-quality, pristine graphene flakes. However, the process is labor-intensive and yields very small quantities, making it unsuitable for anything beyond fundamental lab research.

Chemical Oxidation & Reduction (Top-Down)

This is a highly scalable method for bulk production. Graphite is first treated with strong oxidizing agents to produce graphene oxide (GO), which separates the layers and makes them dispersible in water.

This GO is then chemically or thermally "reduced" to remove the oxygen groups and restore the graphene structure. This method is cost-effective for producing large quantities of graphene flakes for use in composites, inks, and coatings.

Chemical Vapor Deposition (CVD) (Bottom-Up)

CVD is the leading method for producing large-area, high-quality graphene films, especially for electronics.

The process involves introducing a carbon-containing gas (like methane) into a high-temperature chamber (800–1050 °C) containing a metal substrate, typically a copper or nickel foil.

At low pressures, the gas decomposes, and carbon atoms deposit onto the metal surface, self-organizing into a continuous, single-atom-thick layer of graphene. This method has been developed for wafer-scale production.

Understanding the Trade-offs

No single method is universally superior; the best choice is dictated entirely by the end-use application and its specific requirements.

Quality vs. Quantity

Mechanical exfoliation yields the highest electronic quality but produces minuscule amounts.

Chemical oxidation provides enormous quantity but the resulting graphene often contains structural defects and residual oxygen, which can compromise its properties.

CVD offers a powerful balance, producing large areas of high-quality graphene, though transferring it from its growth substrate can introduce impurities or tears.

Scalability and Cost

Chemical methods are the most scalable and cost-effective for bulk powder production. The required equipment is relatively common in chemical processing.

CVD is the most scalable method for producing large, continuous sheets. However, it requires specialized, high-temperature vacuum equipment, making the initial capital investment significant.

The Importance of the Final Application

The required purity and structure of the graphene are dictated by the goal.

Advanced electronics require a near-perfect, defect-free lattice, making CVD the industry standard. Composites or conductive inks can tolerate a higher level of defects, making chemically derived graphene a practical and economical choice.

Making the Right Choice for Your Goal

Your application determines the correct synthesis path.

- If your primary focus is fundamental research or prototyping novel electronic devices: Mechanical exfoliation provides the highest quality flakes for initial discovery.

- If your primary focus is industrial-scale use in composites, coatings, or conductive inks: Chemical oxidation and reduction is the most cost-effective path for producing bulk quantities.

- If your primary focus is creating wafer-scale films for advanced electronics and sensors: Chemical Vapor Deposition (CVD) is the established method for producing large, high-quality, and uniform sheets.

Choosing the correct synthesis method is the first and most critical step in harnessing the power of graphene for a specific task.

Summary Table:

| Method | Approach | Best For | Key Characteristic |

|---|---|---|---|

| Mechanical Exfoliation | Top-Down | Fundamental Research | Highest quality, very low yield |

| Chemical Oxidation/Reduction | Top-Down | Composites, Inks (Bulk) | Cost-effective, scalable, some defects |

| Chemical Vapor Deposition (CVD) | Bottom-Up | Electronics, Sensors | High-quality, large-area films |

Ready to integrate graphene into your research or production?

The right synthesis method is critical to your project's success. KINTEK specializes in providing the lab equipment and consumables—from CVD systems to chemical processing tools—needed to reliably produce graphene for your specific application, whether you're focused on high-purity electronics or scalable composite materials.

Contact our experts today to discuss your requirements and find the optimal solution for your laboratory's needs.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- What is an example of chemical vapor deposition CVD? Creating the Microchips That Power Our World

- What is the process of cathode sputtering? A Step-by-Step Guide to Thin Film Deposition

- What is the process of CVD coating? A Step-by-Step Guide to High-Performance Thin Films

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- What role does CVD equipment play in single-layer graphene-coated metal catalysts? Unlock High-Performance Stability

- What is the role of CVD equipment in nano-diamond thin film precursors? Achieve Precision Synthesis

- How is an ultrasonic bath utilized during the diamond seeding phase of substrate preparation? Enhance CVD Nucleation

- Which gases are used in CVD diamond process? Unlock the Secrets of Lab-Grown Diamond Creation