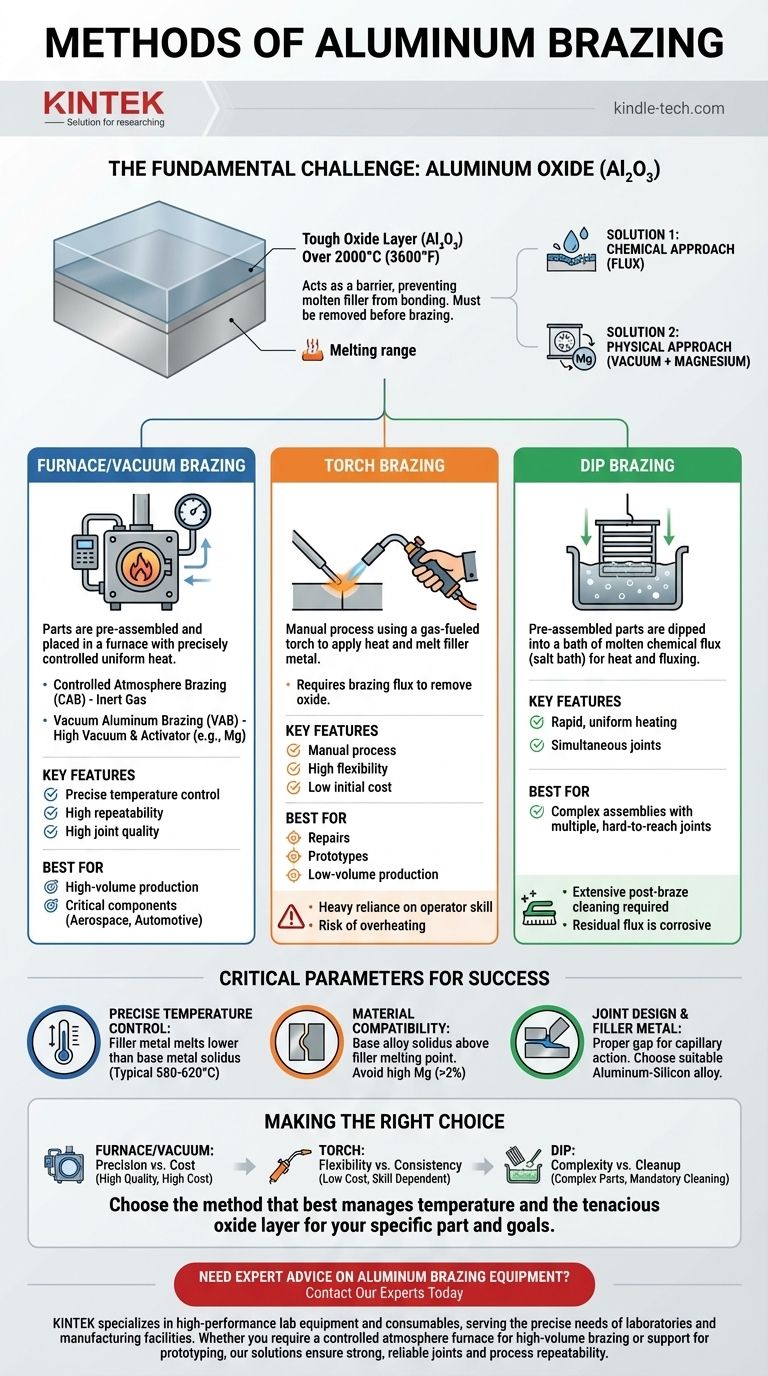

The primary methods for brazing aluminum are furnace brazing (including controlled atmosphere and vacuum), torch brazing, and dip brazing. Each method offers a different way to apply heat and control the environment, but all must overcome the fundamental challenges of working with aluminum, namely its persistent oxide layer and narrow brazing temperature window.

The success of any aluminum brazing method hinges less on the heat source and more on the precise control of two critical factors: defeating the stubborn aluminum oxide (Al₂O₃) layer and maintaining a uniform temperature just below the base metal's melting point.

The Fundamental Challenge: Aluminum Oxide

Why Al₂O₃ is a Problem

Every aluminum surface is instantly covered by a thin, tough, and transparent layer of aluminum oxide. This layer has a very high melting point (over 2000°C / 3600°F), which is far above the melting point of the aluminum itself.

This stable oxide film acts as a barrier, preventing the molten filler metal from "wetting" or bonding with the underlying base aluminum, making a brazed joint impossible without first removing it.

Defeating the Oxide Layer

Two primary strategies are used to overcome this oxide layer. The first is a chemical approach using a flux, which dissolves the oxide. The second is a physical approach using a vacuum combined with a metal activator.

In vacuum brazing, a high vacuum removes most of the oxygen. An activator metal, typically magnesium (Mg), is introduced, which vaporizes at brazing temperature and aggressively combines with any remaining oxygen, effectively breaking down the oxide layer on the part's surface.

Key Brazing Methods Explained

Furnace Brazing (Including Vacuum)

This is the most common method for high-volume production, especially for the automotive and aerospace industries. Parts are pre-assembled with the filler metal and placed inside a furnace.

The furnace provides highly uniform, precisely controlled heat. Controlled Atmosphere Brazing (CAB) uses an inert gas, while Vacuum Aluminum Brazing (VAB) uses a vacuum, often considered the highest-quality method for critical applications.

Torch Brazing

Torch brazing is a manual process used for repairs, prototypes, or low-volume production. An operator uses a gas-fueled torch to heat the assembly and melt the filler metal.

This method requires significant operator skill to apply heat evenly and avoid overheating or melting the thin aluminum parts. A brazing flux is almost always required to remove the oxide layer.

Dip Brazing

In this method, the pre-assembled parts are dipped into a bath of molten chemical flux (a salt bath). The bath serves as both the source of heat and the fluxing agent.

Dip brazing provides rapid, uniform heating and is excellent for producing complex assemblies with many joints. However, it requires extensive post-braze cleaning to remove all residual flux, which can be corrosive.

Critical Parameters for a Successful Braze

Precise Temperature Control

This is the most critical factor. The filler metal must melt and flow at a temperature lower than the base metal's solidus temperature (the point where it begins to melt).

Typical aluminum filler metals melt between 580-620°C (1076-1148°F). Furnaces achieve this control through multiple heating zones and careful design, ensuring the heating elements don't overheat the part's surface.

Material Compatibility

Not all aluminum alloys are suitable for brazing. The base alloy's solidus temperature must be safely above the filler metal's melting point.

Furthermore, alloys with high magnesium content (over 2%) are very difficult to braze because they form a highly stable oxide layer that is resistant to removal by standard fluxes or vacuum processes.

Joint Design and Filler Metal

The gap between the parts being joined is critical. Proper joint design ensures the molten filler metal is drawn into the gap by capillary action.

The filler metal, typically an aluminum-silicon alloy, is chosen based on its melting point and flow characteristics to create a strong, leak-tight metallurgical bond upon cooling.

Understanding the Trade-offs

Furnace/Vacuum Brazing: Precision vs. Cost

This method offers the highest level of control, repeatability, and joint quality, making it ideal for critical components in aerospace or semiconductors. However, the equipment cost is high, and it is best suited for mass production.

Torch Brazing: Flexibility vs. Consistency

Torch brazing has a very low initial cost and is highly portable and flexible for one-off jobs or repairs. Its primary drawback is a heavy reliance on operator skill, which can lead to inconsistent quality and a higher risk of part failure from overheating.

Dip Brazing: Complexity vs. Cleanup

This method excels at joining highly complex assemblies with multiple, hard-to-reach joints simultaneously. The major trade-off is the mandatory and thorough post-brazing cleaning process to prevent corrosion from the residual salt flux.

Making the Right Choice for Your Application

Choosing the right method requires matching the process capabilities to your project's specific needs for quality, volume, and complexity.

- If your primary focus is high-volume production or complex, critical joints: Furnace or vacuum brazing offers the necessary control and repeatability.

- If your primary focus is low-volume prototyping, repairs, or simple joints: Manual torch brazing is the most cost-effective and flexible option.

- If your primary focus is intricate assemblies with many simultaneous joints: Dip brazing provides excellent heat uniformity, provided you can manage the post-process cleaning.

Ultimately, a successful aluminum braze is the result of choosing the method that best manages temperature and the tenacious oxide layer for your specific part and production goals.

Summary Table:

| Method | Key Feature | Best For |

|---|---|---|

| Furnace/Vacuum Brazing | Precise temperature control, high repeatability | High-volume production, critical components (aerospace, automotive) |

| Torch Brazing | Manual process, high flexibility | Repairs, prototypes, low-volume production |

| Dip Brazing | Rapid, uniform heating in a molten salt bath | Complex assemblies with multiple joints |

Need expert advice on aluminum brazing equipment for your lab or production line?

KINTEK specializes in high-performance lab equipment and consumables, serving the precise needs of laboratories and manufacturing facilities. Whether you require a controlled atmosphere furnace for high-volume brazing or support for prototyping, our solutions ensure strong, reliable joints and process repeatability.

Contact our experts today to discuss how we can optimize your aluminum brazing process.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the different types of brazing welding? A Guide to Choosing the Right Heat Source

- What is brazing in heat treatment? Achieve Superior Joint Quality and Efficiency

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance