The primary methods of sintering involve applying energy, typically heat, to a powder compact to bond its particles and increase its density. These methods can be broadly categorized into conventional solid-state sintering, pressure-assisted techniques like Hot Isostatic Pressing (HIP) and Spark Plasma Sintering (SPS), and advanced energy-beam methods used in additive manufacturing, such as Selective Laser Sintering (SLS). The choice of method depends entirely on the material, the desired final properties, and production constraints like cost and speed.

Choosing a sintering method is not about finding the single "best" technique, but about selecting the right tool for the job. The decision is a calculated trade-off between the desired density, processing speed, material constraints, and overall cost.

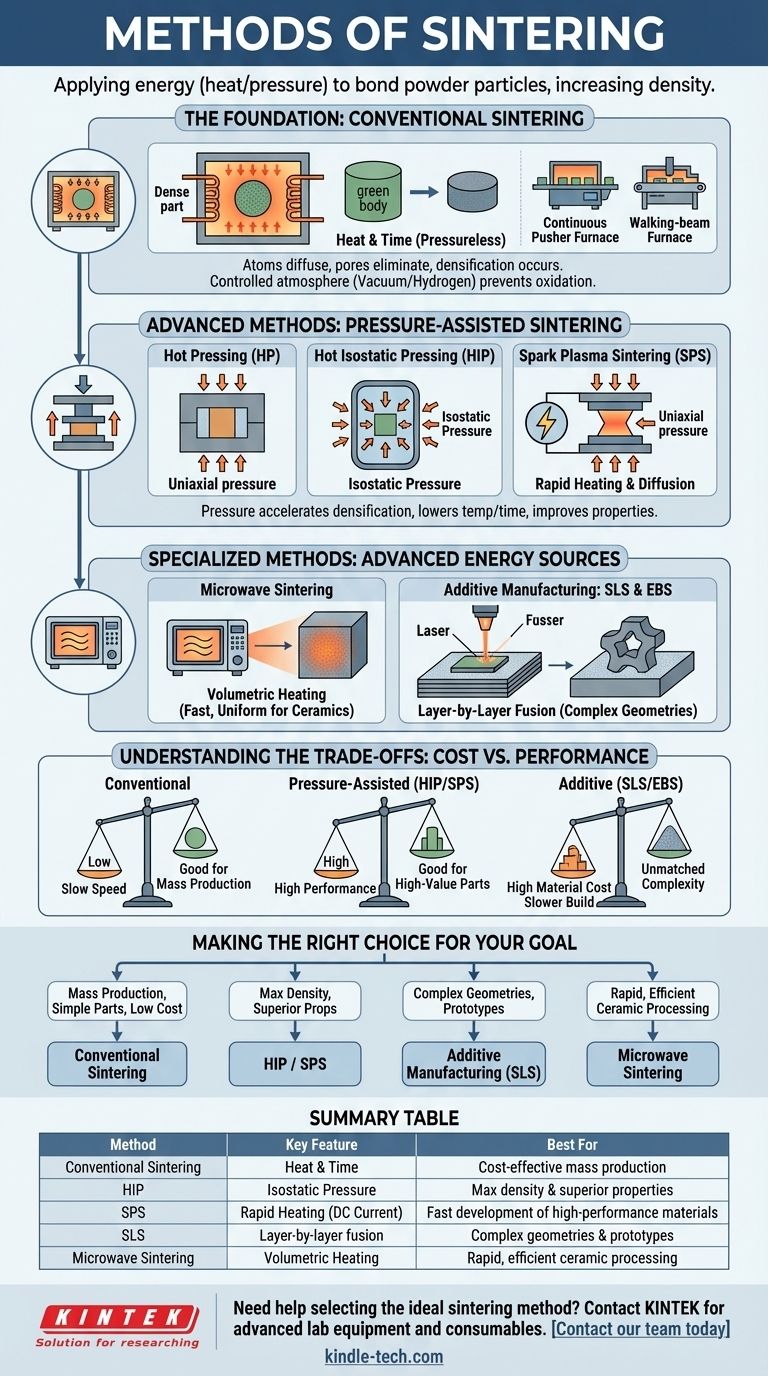

The Foundation: Conventional Sintering

Conventional sintering, also known as solid-state or pressureless sintering, is the most traditional and widely used method. It forms the baseline against which other techniques are compared.

The Core Principle: Heat and Time

This process involves heating a compacted powder part, often called a "green body," to a temperature below its melting point.

At this high temperature, atoms diffuse across the boundaries of the particles, causing them to fuse and gradually eliminate the pore spaces between them. This process, known as densification, increases the part's strength and density.

Controlling the Furnace Atmosphere

The atmosphere inside the furnace is critical. A controlled environment prevents unwanted chemical reactions, like oxidation, which can compromise the material's properties.

Common approaches include vacuum sintering, which removes reactive gases, or using a protective gas like hydrogen, particularly for materials like cemented carbides.

Common Furnace Types

For industrial-scale production, continuous furnaces are often used. Pusher furnaces move parts on a series of plates through the heating zones.

Walking-beam furnaces use a more complex mechanism to lift and "walk" the parts through the furnace, offering precise control over the process.

Advanced Methods: Pressure-Assisted Sintering

To improve densification and reduce processing time, external pressure can be applied simultaneously with heat. This is the basis of all pressure-assisted sintering methods.

Why Add Pressure?

Applying pressure dramatically accelerates the densification process. It allows for sintering at lower temperatures and for shorter times, which helps prevent unwanted grain growth and results in parts with superior mechanical properties.

Hot Pressing (HP)

Hot pressing involves applying uniaxial pressure—pressure from a single direction—to the powder in a die while it is being heated. This is effective for producing simple shapes with high density.

Hot Isostatic Pressing (HIP)

HIP places the part in a high-pressure vessel and applies isotropic pressure—equal pressure from all directions—using an inert gas. This method is excellent for eliminating any remaining internal porosity and creating parts with nearly 100% theoretical density.

Spark Plasma Sintering (SPS)

SPS is a more advanced technique that uses a pulsed DC current to rapidly heat the powder compact while simultaneously applying uniaxial pressure. The plasma generated between particles enhances diffusion, allowing for extremely fast sintering cycles, often in just a few minutes.

Specialized Methods: Advanced Energy Sources

Beyond conventional heating and pressure, specialized methods use focused energy sources to achieve unique outcomes, particularly in the realm of additive manufacturing.

Microwave Sintering

This method uses microwave radiation to heat the material. Unlike a conventional furnace that heats from the outside in, microwaves can generate heat volumetrically throughout the part. This leads to more uniform heating and significantly faster, more energy-efficient processing for suitable materials like many ceramics.

Additive Manufacturing: SLS and EBS

Selective Laser Sintering (SLS) and Electron Beam Sintering (EBS) are core additive manufacturing (3D printing) technologies.

These processes use a high-energy beam (a laser or an electron beam) to selectively fuse regions of a powder bed, building a solid object layer by layer. This allows for the creation of incredibly complex geometries that are impossible to produce with traditional methods.

Understanding the Trade-offs: Cost vs. Performance

Each sintering method comes with a distinct set of advantages and limitations. Understanding these trade-offs is crucial for making an informed decision.

Conventional Sintering: Cost-Effective but Slow

This method is the workhorse for high-volume production of less-critical parts due to its relatively low equipment cost and scalability. However, it is slow, energy-intensive, and may not achieve the highest possible density.

Pressure-Assisted Methods: High Performance, High Cost

Techniques like HIP and SPS deliver superior density and mechanical properties. This performance comes at the price of highly specialized, expensive equipment and typically lower production throughput, making them ideal for high-value applications in aerospace, medical, and defense.

Additive Methods (SLS/EBS): Unmatched Complexity, Specialized Use

SLS and similar techniques offer unparalleled design freedom for creating complex prototypes and custom parts. The trade-off is high material cost, slower build times per part, and a focus on geometric complexity rather than mass production.

Making the Right Choice for Your Goal

Your choice must be driven by your end goal. After defining the required material properties, geometry, and production volume, you can select the most appropriate method.

- If your primary focus is mass production of simple parts at a low cost: Conventional solid-state sintering is the most logical choice.

- If your primary focus is achieving maximum density and superior mechanical properties: Pressure-assisted methods like HIP for final densification or SPS for rapid development are the best options.

- If your primary focus is creating complex, one-off geometries or prototypes: Additive manufacturing techniques like Selective Laser Sintering (SLS) are the only viable path.

- If your primary focus is rapid, energy-efficient processing of specific ceramics: Microwave sintering offers a compelling advantage over conventional methods.

Ultimately, the most effective sintering strategy directly aligns the chosen method with the specific demands of the material and its final application.

Summary Table:

| Method | Key Feature | Best For |

|---|---|---|

| Conventional Sintering | Heat and time (pressureless) | Cost-effective mass production of simple parts |

| Hot Isostatic Pressing (HIP) | Isostatic pressure (all directions) | Maximum density and superior mechanical properties |

| Spark Plasma Sintering (SPS) | Rapid heating with pulsed DC current | Fast development of high-performance materials |

| Selective Laser Sintering (SLS) | Layer-by-layer fusion with a laser | Complex geometries and prototypes (Additive Manufacturing) |

| Microwave Sintering | Volumetric heating | Rapid, energy-efficient processing of ceramics |

Need help selecting the ideal sintering method for your lab's materials?

The right sintering technique is critical for achieving the desired density, properties, and cost-efficiency in your research or production. KINTEK specializes in providing advanced lab equipment and consumables to meet your specific sintering needs, whether you're working with ceramics, metals, or complex composites.

Let our experts guide you to the optimal solution. Contact our team today to discuss your application and discover how KINTEK can enhance your sintering processes.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What are the advantages of vacuum sintering? Achieve Superior Purity, Strength, and Performance

- How does a vacuum environment system contribute to the hot pressing sintering of B4C-CeB6? Unlock Peak Ceramic Density

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What conditions does a vacuum hot press provide for Al2O3/ZrO2 sintering? Achieve 1550°C and 30 MPa Densification

- What is the pressure for vacuum sintering? Achieve Optimal Material Purity and Density