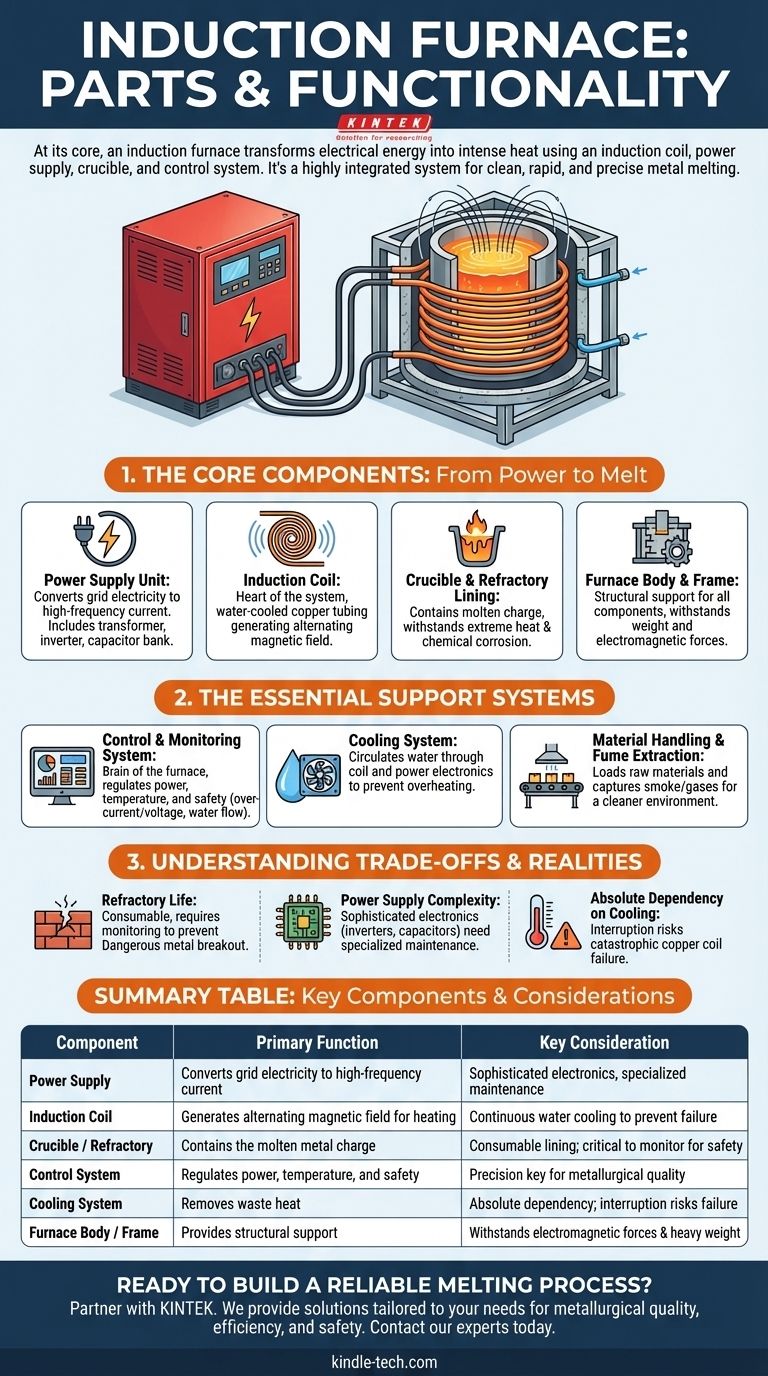

At its core, an induction furnace is comprised of a power supply, an induction coil, a crucible, and a control system. These primary components work together within a structural furnace body to transform electrical energy into intense heat. Essential support systems, particularly for cooling and material handling, are integrated to ensure safe, continuous, and efficient operation.

An induction furnace is not merely a collection of parts, but a highly integrated system. Each component is engineered to contribute to a singular goal: converting electricity into a controlled magnetic field to achieve clean, rapid, and precise melting of metals.

The Core Components: From Power to Melt

The primary function of the furnace is to contain and melt the charge material. This is accomplished through the direct interaction of a few key parts that handle power conversion and magnetic field generation.

The Power Supply Unit

The power supply is the engine of the furnace. It takes standard grid electricity and converts it into the specific frequency and high-amperage current required for induction heating. It typically includes a transformer, an inverter for frequency conversion, and a capacitor bank to optimize the power factor.

The Induction Coil

This is the heart of the system. The induction coil is a helical or spiral-shaped conductor, usually made of heavy-walled copper tubing. An alternating current flows through this coil, generating a powerful and rapidly alternating magnetic field in the center of the coil where the crucible sits.

The Crucible and Refractory Lining

The crucible is the container that holds the metal charge. It is made from high-performance refractory materials designed to withstand extreme thermal shock and chemical corrosion from molten metal. This lining is critical for both containing the melt and preventing electrical contact with the induction coil.

The Furnace Body and Frame

The furnace body is the structural steel framework that houses and supports the crucible and induction coil. It is engineered to withstand the immense weight of the charge and the electromagnetic forces generated during operation.

The Essential Support Systems

To function reliably and safely, the core components rely on several critical support systems. These systems manage heat, monitor the process, and handle materials, making industrial-scale operation possible.

The Control and Monitoring System

This system is the brain of the furnace. It regulates the power output to control the melting rate and temperature with high precision. It also serves a vital safety function by monitoring for over-current, over-voltage, and failures in other systems, such as water flow.

The Cooling System

Immense electrical currents flowing through the induction coil and power electronics generate significant waste heat. A robust cooling system, almost always using water, circulates through the copper coil and power supply components to prevent them from overheating and failing catastrophically.

Material Handling and Fume Extraction

In an industrial setting, furnaces include a charging system to load raw materials into the crucible. A fume extraction hood is also essential to capture and filter any smoke or gases released during the melting process, ensuring a cleaner and safer work environment.

Understanding the Trade-offs and Realities

While highly efficient, induction furnaces have operational complexities that require careful management. Understanding these trade-offs is key to successful implementation.

The Critical Role of Refractory Life

The crucible's refractory lining is a consumable item. It degrades over time due to thermal and chemical stress, making it a primary point of failure and a recurring operational cost. Its condition must be constantly monitored to prevent a dangerous metal breakout.

Power Supply Complexity

The high-frequency power supply unit is a sophisticated piece of electronic equipment. While it enables incredible efficiency and control, its components (like the inverter and capacitors) can be a source of failure and require specialized maintenance.

Absolute Dependency on Cooling

The entire furnace operation is critically dependent on the cooling system. Any interruption in water flow, even for a short period, can cause the copper coil to overheat and melt, resulting in a costly and dangerous failure. This is why water deficiency protection is a standard safety feature.

Making the Right Choice for Your Goal

The specific design and emphasis on certain components will vary based on the primary objective of the furnace application.

- If your primary focus is operational efficiency: Pay closest attention to the power supply's inverter technology and capacitor bank, as these dictate energy conversion and power factor correction.

- If your primary focus is metallurgical quality: The precision of your control system and its temperature feedback loops are the most critical elements for preserving valuable alloys and achieving consistent results.

- If your primary focus is safety and reliability: Your design must prioritize a robust, closed-loop cooling circuit and a comprehensive monitoring system with automatic safety shutdowns.

Understanding how these individual parts form a single, dynamic system is the key to mastering induction furnace technology.

Summary Table:

| Component | Primary Function | Key Consideration |

|---|---|---|

| Power Supply | Converts grid electricity to high-frequency current | Sophisticated electronics requiring specialized maintenance |

| Induction Coil | Generates the alternating magnetic field for heating | Requires continuous water cooling to prevent failure |

| Crucible / Refractory | Contains the molten metal charge | A consumable lining; critical to monitor for safety |

| Control System | Regulates power, temperature, and monitors for safety | Precision is key for metallurgical quality and repeatability |

| Cooling System | Removes waste heat from coil and power electronics | Absolute dependency; any interruption risks catastrophic failure |

| Furnace Body / Frame | Provides structural support for all components | Must withstand electromagnetic forces and heavy charge weight |

Ready to build a reliable and efficient melting process?

Understanding the intricate parts of an induction furnace is the first step. The next is partnering with an expert who can provide the right equipment and support for your specific laboratory or production goals—whether your focus is on metallurgical quality, operational efficiency, or utmost safety.

KINTEK specializes in high-performance lab equipment, including induction furnaces and consumables. We provide solutions tailored to your needs, ensuring you get the precise temperature control, durability, and reliability your work demands.

Contact our experts today to discuss how our induction furnaces can enhance your melting capabilities.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What is the primary advantage of using a tube furnace? Achieve Superior Temperature and Atmosphere Control

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.