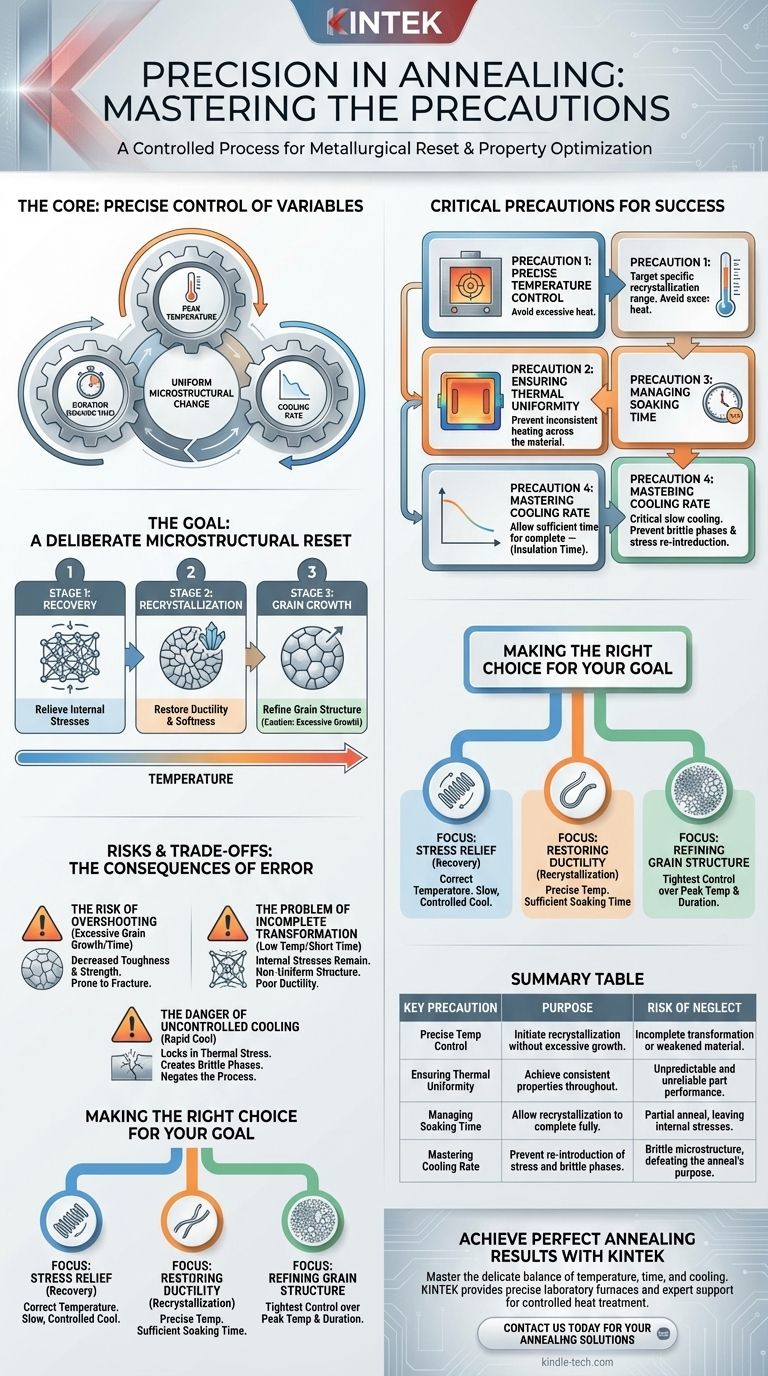

At its core, the primary precautions for annealing involve the precise control of three variables: the peak temperature, the duration the material is held at that temperature, and the rate of cooling. These factors must be managed meticulously to ensure the desired changes in the material's internal structure are achieved uniformly and completely, without introducing new defects.

Annealing is not simply a matter of heating and cooling a material. It is a controlled process of metallurgical transformation where every precaution is designed to guide the material’s microstructure toward a specific, improved state.

The Goal: A Deliberate Microstructural Reset

Annealing is performed to relieve internal stresses, increase softness and ductility, and refine the grain structure of a material that has been hardened or stressed by processes like cold working. This is accomplished by progressing through three distinct stages.

Stage 1: Recovery

This initial stage occurs at lower temperatures. The primary goal here is to relieve the internal stresses stored within the material's crystal lattice without significantly changing its larger grain structure.

Stage 2: Recrystallization

As the temperature increases to a specific point for the given alloy, new, strain-free grains begin to form and replace the deformed, stress-filled grains. This is the heart of the annealing process, responsible for restoring ductility and softness.

Stage 3: Grain Growth

If the material is held at the annealing temperature for too long or at too high a temperature, the newly formed, strain-free grains will begin to grow larger. While some grain growth can be desirable, excessive growth can reduce the material's strength and toughness.

Critical Precautions for a Successful Anneal

Each precaution is directly linked to successfully navigating the three stages of transformation. Failure to control any step can compromise the final properties of the material.

Precaution 1: Precise Temperature Control

The annealing temperature must be high enough to initiate recrystallization but not so high that it causes excessive or rapid grain growth. Every alloy has a specific recrystallization temperature range that must be targeted accurately.

Precaution 2: Ensuring Thermal Uniformity

The temperature throughout the furnace and the material itself must be as uniform as possible. Inconsistent heating leads to some sections being fully annealed while others are not, resulting in unpredictable and unreliable material properties across the component.

Precaution 3: Managing the Soaking (Insulation) Time

Once at temperature, the material must be held, or soaked, for a sufficient period. The references refer to this as the insulation time. This step is crucial to allow the recrystallization process to complete throughout the entire volume of the material.

Precaution 4: Mastering the Cooling Rate

For most annealing processes, slow cooling is critical. Rapid cooling can re-introduce thermal stresses or, in certain alloys like steel, create hard and brittle microstructures (like martensite), completely defeating the purpose of the anneal. The cooling rate must be slow enough to allow the structure to settle into a stable, stress-free state.

Understanding the Risks and Trade-offs

Deviating from these precautions introduces specific, undesirable outcomes. Understanding these risks highlights the importance of process control.

The Risk of Overshooting: Excessive Grain Growth

Holding the material at too high a temperature or for too long will cause the newly formed grains to grow too large. This can significantly decrease the material's toughness and strength, making it more prone to fracture.

The Problem of Incomplete Transformation

Using a temperature that is too low or a soaking time that is too short will result in an incomplete anneal. The material will not fully recrystallize, leaving behind internal stresses and a non-uniform grain structure, which fails to restore the desired ductility.

The Danger of Uncontrolled Cooling

Cooling the part too quickly is a common mistake that negates the entire process. It locks in thermal stress and can create unintended, brittle phases within the microstructure, potentially making the part weaker or more brittle than it was before the process began.

Making the Right Choice for Your Goal

Your specific goal will determine which precautions you need to emphasize most.

- If your primary focus is stress relief (Recovery): Your main concern is reaching the correct temperature and ensuring a slow, controlled cool-down to prevent new stresses from forming.

- If your primary focus is restoring ductility (Recrystallization): You must be rigorous about achieving the precise annealing temperature and providing sufficient soaking time for a complete transformation.

- If your primary focus is refining grain structure (Controlling Grain Growth): You need the tightest possible control over peak temperature and soaking duration to achieve the target grain size without overshooting.

Successful annealing is achieved not by chance, but by precise and deliberate control over the entire thermal cycle.

Summary Table:

| Key Precaution | Purpose | Risk of Neglect |

|---|---|---|

| Precise Temperature Control | Initiate recrystallization without excessive grain growth. | Incomplete transformation or weakened material. |

| Ensuring Thermal Uniformity | Achieve consistent properties throughout the material. | Unpredictable and unreliable part performance. |

| Managing Soaking Time | Allow recrystallization to complete fully. | Partial anneal, leaving internal stresses. |

| Mastering Cooling Rate | Prevent re-introduction of stress and brittle phases. | Brittle microstructure, defeating the anneal's purpose. |

Achieve Perfect Annealing Results with KINTEK

Mastering the delicate balance of temperature, time, and cooling is essential for achieving the exact material properties you need. KINTEK specializes in providing the precise laboratory furnaces and expert support necessary for controlled heat treatment processes like annealing.

We help our customers in materials testing, research, and production ensure thermal uniformity, accurate temperature control, and programmable cooling cycles for reliable and repeatable results.

Contact us today to discuss your specific annealing requirements and discover how our lab equipment solutions can enhance your process reliability and material performance.

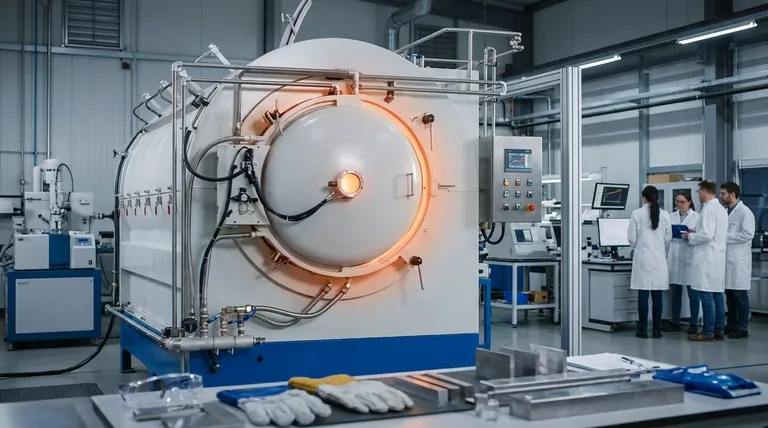

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- How is the greatest joint strength obtained in brazing? Master the 3 Keys to Superior Metallurgical Bonds

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy