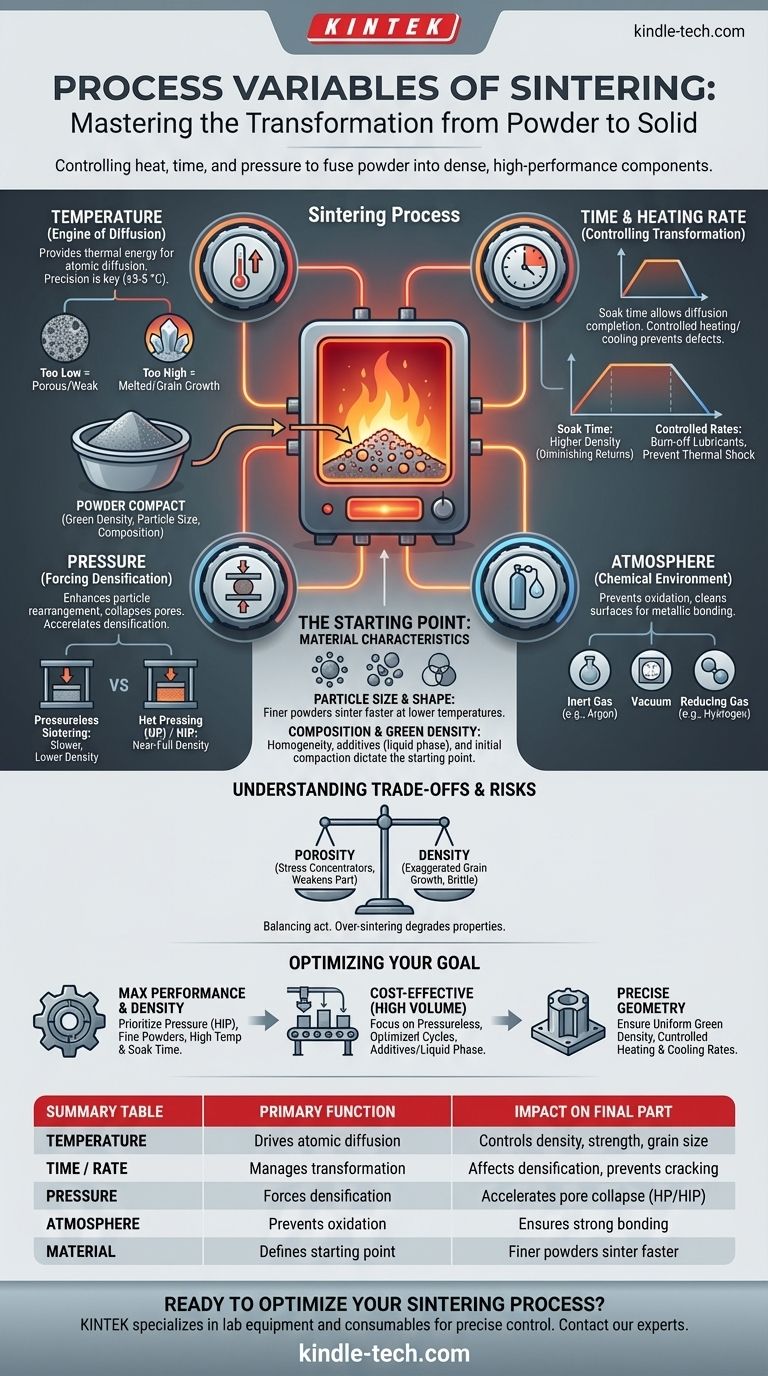

The primary process variables of sintering are temperature, time, pressure, and furnace atmosphere. These external factors act upon the intrinsic variables of the material itself—namely its particle size, composition, and the initial density of the compacted powder. Mastering the interplay between these elements is what determines the success or failure of the process.

Sintering is not a single step, but a controlled transformation. The core challenge is managing heat, time, and pressure to fuse loose powder into a dense, solid object, where each variable directly impacts the final material's strength, porosity, and structural integrity.

The Foundational Pillars of Sintering

The sintering process can be thought of as a recipe where each ingredient and instruction must be precise. The main variables you control are related to the furnace cycle and the environment within it.

Temperature: The Engine of Diffusion

Temperature is the most critical variable in sintering. It provides the thermal energy required for atoms to diffuse across the boundaries of individual particles, causing them to bond and merge.

If the temperature is too low, diffusion will be insufficient, resulting in a porous and weak part. If it's too high, the material can melt, or excessive grain growth can occur, which also degrades mechanical properties. Precision is paramount, often requiring control within ±3-5 °C of the target.

Time and Heating Rate: Controlling the Transformation

The total time the material spends at the peak sintering temperature (known as "soak time") allows the diffusion process to complete. A longer time generally leads to higher density, but there are diminishing returns.

The heating rate (how quickly you reach the peak temperature) and cooling rate are also crucial. A controlled ramp-up is needed to burn off any lubricants from the compaction phase and reduce surface oxides. A controlled cool-down prevents thermal shock and cracking.

Pressure: Forcing Densification

While many parts are sintered without external pressure ("pressureless sintering"), applying pressure during the heating cycle dramatically accelerates densification.

Pressure enhances particle rearrangement, collapses pores more effectively, and can achieve near-full density. This is the principle behind processes like Hot Pressing (HP) and Hot Isostatic Pressing (HIP).

Atmosphere: The Chemical Environment

Sintering is almost never performed in open air. The furnace atmosphere is a controlled variable used to prevent oxidation and, in some cases, to actively clean the particle surfaces.

Common atmospheres include inert gases (like argon), vacuum, or reducing gases (like hydrogen). The right atmosphere ensures that the particle surfaces are pure, allowing for strong metallic bonds to form.

The Starting Point: Material Characteristics

The process variables above act upon the powder you start with. The initial state of this material dictates how it will respond to heat and pressure.

Particle Size and Shape

Smaller particles have a higher surface-area-to-volume ratio, which provides a greater driving force for sintering. Consequently, finer powders generally sinter at lower temperatures and faster rates, promoting better densification.

Composition and Green Density

The chemical makeup of the powder is fundamental. Homogeneous mixing is vital. Additives, such as binders or elements that form a liquid phase during heating (Liquid Phase Sintering), can be used to accelerate densification by allowing particles to rearrange more easily.

Green density—the density of the part after initial compaction but before heating—is the starting line for the sintering race. A higher green density means there is less empty space to eliminate, making it easier to achieve a fully dense final part.

Understanding the Trade-offs and Risks

Optimizing sintering variables is a balancing act. Pushing one variable to its extreme often creates unintended consequences.

The Balancing Act of Porosity vs. Density

The primary goal of sintering is often to eliminate porosity. However, incomplete sintering leaves residual pores that act as stress concentrators, weakening the part.

Conversely, "over-sintering" at excessively high temperatures or for too long can cause exaggerated grain growth. While the part may be dense, these large grains can make the material brittle.

Material Property Control

The final microstructure of the material, which dictates its strength, hardness, and toughness, is a direct result of the sintering cycle. Incorrect variables will result in a part that fails to meet engineering specifications, even if it looks dimensionally correct.

Economic and Environmental Constraints

Sintering equipment represents a significant capital investment. Processes that require extreme temperatures, long cycle times, or high pressures are more expensive to run.

Furthermore, high-temperature processing can release emissions, and producers must adhere to environmental policies. These regulations can constrain process choices and affect production costs.

Optimizing Sintering for Your Goal

Your choice of process parameters should be driven by the final objective for your component.

- If your primary focus is maximum density and performance: Prioritize pressure-assisted methods like HIP, use fine, high-purity powders, and optimize for higher temperatures and sufficient soak times.

- If your primary focus is cost-effectiveness for high-volume production: Focus on pressureless sintering with optimized heating cycles, and consider using additives or liquid-phase sintering to reduce required temperatures and times.

- If your primary focus is achieving precise geometric shapes: Pay close attention to achieving a high and uniform green density, and implement carefully controlled heating and cooling rates to minimize distortion and warping.

Mastering these variables transforms the art of sintering into a precise and repeatable science.

Summary Table:

| Process Variable | Primary Function | Impact on Final Part |

|---|---|---|

| Temperature | Drives atomic diffusion for particle bonding | Controls density; too low = weak/porous, too high = melting/grain growth |

| Time / Heating Rate | Manages transformation and lubricant burn-off | Affects densification & prevents thermal shock/cracking |

| Pressure | Forces particle rearrangement & pore collapse | Accelerates densification; key for HP/HIP processes |

| Atmosphere | Prevents oxidation & cleans particle surfaces | Ensures strong metallic bonds form (uses H2, Ar, vacuum) |

| Material (Particle Size, Composition) | Defines the starting point for the sintering process | Finer powders sinter faster; additives can enable liquid phase sintering |

Ready to Optimize Your Sintering Process?

Achieving the perfect balance of temperature, time, pressure, and atmosphere is critical for producing high-performance, dense components. The right lab equipment is essential for precise control and repeatable results.

KINTEK specializes in lab equipment and consumables, serving all your laboratory sintering needs. We provide the reliable furnaces and atmosphere control systems you need to master these variables and achieve your material goals—whether for maximum density, cost-effective production, or precise geometries.

Contact our experts today to discuss how our solutions can enhance your sintering process.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the different types of laboratory furnaces? Find the Perfect Fit for Your Application

- Why ceramics can withstand high temperature? Unlock the Secrets of Atomic Structure

- What is ashing in a muffle furnace? Isolate Inorganic Content with Precision

- How do you calibrate a muffle furnace? Achieve Precise Temperature Control for Your Lab

- What are the parts of a muffle furnace? Uncover the Core Components for Precision Heating