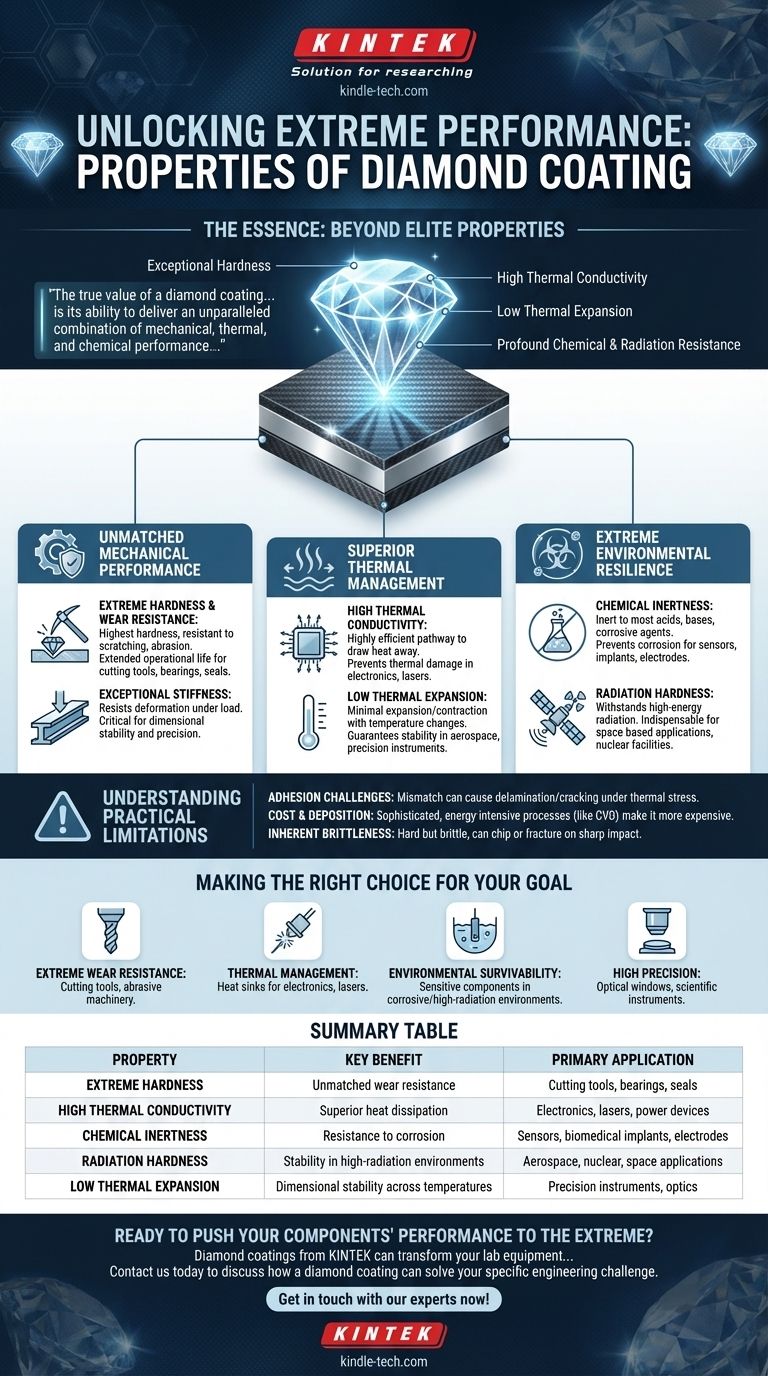

In essence, diamond coatings impart a suite of extreme properties onto the surface of a base material. These coatings are defined by their exceptional hardness, high thermal conductivity, low thermal expansion, and profound chemical and radiation resistance, all stemming from the uniquely strong and rigid covalent bonds of the diamond crystal structure.

The true value of a diamond coating isn't just one of its elite properties, but its ability to deliver an unparalleled combination of mechanical, thermal, and chemical performance where conventional materials would fail.

Unmatched Mechanical Performance

The rigid atomic structure of diamond translates directly into best-in-class performance against physical stress and wear. This makes it a primary choice for applications where longevity and precision are paramount.

Extreme Hardness and Wear Resistance

A diamond coating provides the highest possible level of hardness, making the coated surface exceptionally resistant to scratching, abrasion, and general wear. This property is a direct result of the strong covalent bonds between carbon atoms.

Functionally, this means a significantly extended operational life for components like cutting tools, bearings, and mechanical seals.

Exceptional Stiffness

Beyond simple hardness, diamond is also incredibly stiff, meaning it resists deformation when a load is applied. This high stiffness is critical for applications that demand dimensional stability and precision under pressure.

This ensures that components in high-performance optics or precision manufacturing equipment maintain their exact shape and function without flexing.

Superior Thermal Management

A common misconception is that hard materials are insulators. Diamond coatings defy this by offering thermal properties that are superior to even most metals, making them a critical tool for managing heat in demanding environments.

High Thermal Conductivity

Diamond is one of the most thermally conductive materials known at room temperature. A diamond coating acts as a highly efficient pathway to draw heat away from a critical area.

This prevents thermal damage in high-power electronics, lasers, and other devices that generate intense, localized heat.

Low Thermal Expansion

Diamond coatings have a very low coefficient of thermal expansion. They expand and contract very little when subjected to changes in temperature.

This property guarantees stability and reliability in components that must operate across a wide temperature range without changing their shape or dimensions, such as in aerospace systems or scientific instruments.

Extreme Environmental Resilience

Diamond's stable atomic structure makes it fundamentally resistant to chemical attack and high-energy radiation, enabling components to operate reliably in the most hostile conditions.

Chemical Inertness

Diamond is chemically inert to most acids, bases, and other corrosive agents. A coating effectively seals a component from its environment, preventing corrosion and chemical degradation.

This is essential for sensors used in chemical processing, biomedical implants that must not react with the body, and electrodes in electrochemical applications.

Radiation Hardness

The material is also radiation hard, meaning its crystal lattice can withstand exposure to high-energy radiation without significant damage to its structure or properties.

This resilience is indispensable for electronics and optics used in space-based applications, satellites, and nuclear facilities where radiation exposure is a constant concern.

Understanding the Practical Limitations

While its properties are exceptional, applying a diamond coating is not a universal solution. The primary challenges are not with the material itself, but with the engineering process of applying it effectively.

Adhesion and Substrate Compatibility

The biggest challenge is ensuring the diamond film adheres strongly to the underlying material (the substrate). A mismatch in thermal expansion between the coating and substrate can cause the film to delaminate or crack under thermal stress.

Cost and Deposition Process

Creating a high-quality diamond coating requires sophisticated and energy-intensive processes like Chemical Vapor Deposition (CVD). This makes it a more expensive option compared to other hard coatings like nitrides or carbides.

Inherent Brittleness

Like bulk diamond, diamond coatings are brittle. While they are incredibly hard and resistant to abrasive wear, a sharp, high-energy impact can cause them to chip or fracture rather than deform.

Making the Right Choice for Your Goal

Applying this knowledge depends entirely on your primary engineering challenge.

- If your primary focus is extreme wear resistance: A diamond coating is the optimal choice for extending the life of cutting tools, abrasive machinery, or high-contact mechanical parts.

- If your primary focus is thermal management: It is an ideal solution for creating high-performance heat sinks for dense electronics, laser diodes, or power transistors.

- If your primary focus is environmental survivability: Use a diamond coating to protect sensitive components from corrosive chemicals, bodily fluids, or high-radiation environments.

- If your primary focus is high precision: Its combination of stiffness and thermal stability makes it perfect for optical windows, scientific instruments, and high-fidelity audio components.

Ultimately, a diamond coating is the definitive choice for pushing the performance boundaries of a component far beyond conventional limits.

Summary Table:

| Property | Key Benefit | Primary Application |

|---|---|---|

| Extreme Hardness | Unmatched wear resistance | Cutting tools, bearings, seals |

| High Thermal Conductivity | Superior heat dissipation | Electronics, lasers, power devices |

| Chemical Inertness | Resistance to corrosion | Sensors, biomedical implants, electrodes |

| Radiation Hardness | Stability in high-radiation environments | Aerospace, nuclear, and space applications |

| Low Thermal Expansion | Dimensional stability across temperatures | Precision instruments, optics |

Ready to push your components' performance to the extreme?

Diamond coatings from KINTEK can transform your lab equipment and consumables, delivering unparalleled wear resistance, thermal management, and environmental protection. Whether you're developing cutting-edge electronics, precision instruments, or components for harsh environments, our expertise in advanced coatings can provide the solution you need.

Contact us today to discuss how a diamond coating can solve your specific engineering challenge and extend the life of your critical components.

Get in touch with our experts now!

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Dressing Tools for Precision Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- Is carbon nanotube a simple molecular structure? Unveiling the Complex Atomic Architecture

- What are the catalysts used in CVD? Unlocking Nanomaterial Growth with Metal Catalysts

- What is the principle of sputtering? A Guide to Thin Film Deposition Technology

- Do CVD diamonds test real? Yes, They Pass Standard Diamond Tests

- What is the capacity of carbon nanotubes? Unlock Their Potential in Electronics, Energy, and Materials

- What are thin films made of? Metals, Ceramics, Semiconductors, and Polymers

- Are carbon nanotubes hard to make? Mastering the Challenge of Scalable, High-Quality Production

- What is the sputtering yield? The Key Metric for Efficient Thin-Film Deposition