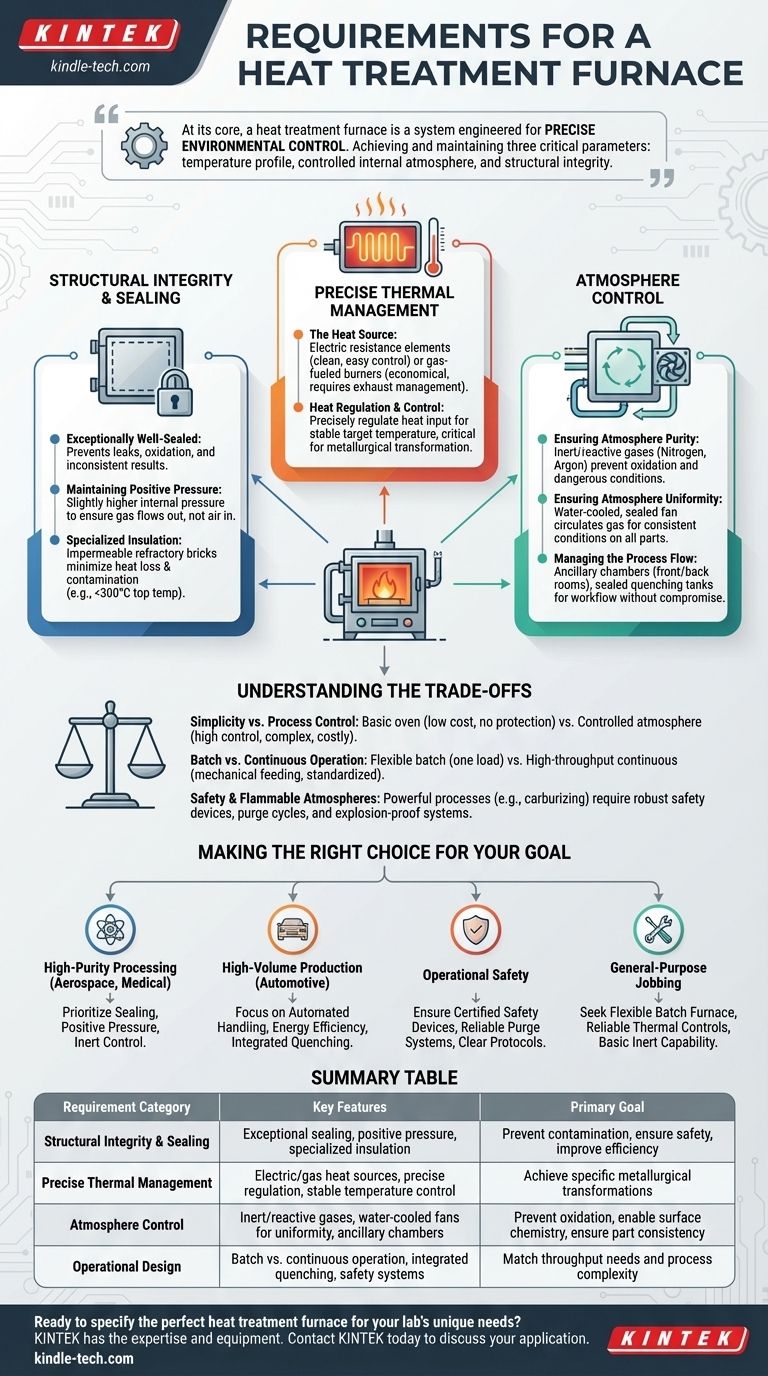

At its core, a heat treatment furnace is a system engineered for precise environmental control. The fundamental requirements center on achieving and maintaining three critical parameters: a specific temperature profile, a controlled internal atmosphere, and structural integrity to contain both safely and efficiently. These requirements ensure the furnace can reliably alter the physical and chemical properties of a material.

A heat treatment furnace is much more than a simple oven. Its design requirements are driven by the need to create a perfectly sealed and stable environment where heat and atmosphere can be precisely manipulated to achieve specific, repeatable metallurgical outcomes without contamination or safety hazards.

The Foundation: Structural Integrity and Sealing

The physical body of the furnace is the first line of defense in maintaining a controlled process. Its design directly impacts both efficiency and the quality of the final product.

### The Importance of a Sealed Chamber

A heat treatment furnace must be exceptionally well-sealed. Any leaks prevent the system from maintaining a stable internal environment.

This is done to prevent the intrusion of outside air and the leakage of the internal controlled atmosphere. A compromised seal leads to oxidation, unwanted chemical reactions, and inconsistent results.

### Maintaining Positive Pressure

To supplement the seal, furnaces are designed to operate under a slight positive pressure.

This means the pressure inside the furnace is slightly higher than the atmospheric pressure outside. This design ensures that if any microscopic leak were to exist, the furnace gas would flow out rather than allowing air (containing oxygen and moisture) to flow in.

### Specialized Insulation

The furnace lining must provide superior thermal insulation and be non-reactive with the furnace atmosphere. For certain processes like carburizing, impermeable refractory bricks are used.

This insulation minimizes heat loss, improving energy efficiency, and ensures the lining material itself doesn't break down or contaminate the process. The furnace top temperature, for instance, should generally not exceed 300°C, indicating effective heat containment.

The Core Function: Precise Thermal Management

The primary purpose of the furnace is to apply heat. However, the way heat is generated, delivered, and controlled is what separates a basic oven from a piece of industrial equipment.

### The Heat Source

Furnaces use one of two primary heat sources: electric resistance elements or gas-fueled burners.

The choice of heating element depends on the required temperature, the type of atmosphere used, and operational cost. Electric heat is often cleaner and easier to control, while gas can be more economical but may require measures to keep combustion byproducts from affecting the parts.

### Heat Regulation and Control

The control system must be able to manage different heating phases. A large amount of energy is needed to bring the furnace and its load up to temperature.

Once the target temperature is reached, the system must precisely regulate the heat input to maintain that temperature with minimal fluctuation. This stability is critical for achieving the desired metallurgical transformation.

The Critical Variable: Atmosphere Control

For most advanced heat treatments, controlling the chemical composition of the gas inside the furnace is just as important as controlling the temperature. This is known as a controllable atmosphere.

### Ensuring Atmosphere Purity

The purpose of a controlled atmosphere, often using gases like nitrogen or argon, is to create an inert or reactive environment.

An inert atmosphere prevents oxidation and scaling on the part's surface. It is also used to purge the furnace of flammable gases or oxygen before and after a cycle, which is a critical safety measure.

### Ensuring Atmosphere Uniformity

The atmosphere's composition must be consistent throughout the entire chamber. This is achieved with a water-cooled, sealed fan.

This fan circulates the furnace gas, eliminating dead spots and ensuring every surface of every part is exposed to the same atmospheric conditions. This is especially vital in lower-temperature processes where natural convection is less effective.

### Managing the Process Flow

Complex furnaces include ancillary chambers to manage the workflow without compromising the main heating chamber. These include front and back rooms or vestibules.

These chambers allow for loading and unloading parts. The furnace may also integrate a sealed quenching tank, allowing parts to be moved directly from the hot zone into a quenching fluid (like oil or water) without exposure to outside air.

Understanding the Trade-offs

Selecting or designing a furnace involves balancing competing priorities. There is no single "best" configuration; the optimal choice depends entirely on the application.

### Simplicity vs. Process Control

A simple, air-atmosphere tempering oven is relatively inexpensive and easy to operate. However, it offers no protection against oxidation. A controllable atmosphere furnace with integrated quenching provides vastly superior control and versatility but comes with significantly higher cost, complexity, and maintenance requirements.

### Batch vs. Continuous Operation

Batch furnaces, which process one load at a time, offer flexibility for a variety of part shapes and process cycles. Continuous furnaces, which use mechanical feeding and discharging devices to move parts through constantly, offer higher throughput and efficiency for high-volume, standardized production but are far less flexible.

### Safety and Flammable Atmospheres

Using flammable atmospheres (like endothermic gas for carburizing) enables powerful metallurgical processes but introduces significant safety risks. These furnaces demand robust safety and explosion-proof devices, including purge cycles, flame supervision systems, and emergency vents, which add to the furnace's complexity and cost.

Making the Right Choice for Your Goal

Your specific requirements for a heat treatment furnace are dictated by your end goal. Use this guide to prioritize the features that matter most to your application.

- If your primary focus is high-purity processing (e.g., aerospace, medical): Prioritize exceptional sealing, positive pressure capability, and precise inert atmosphere control to prevent any surface contamination.

- If your primary focus is high-volume production (e.g., automotive): Focus on automated mechanical handling for continuous operation, energy efficiency, and integrated quenching for a streamlined workflow.

- If your primary focus is operational safety: Ensure the furnace has certified safety devices, reliable purge systems, and clear protocols, especially if using flammable atmospheres.

- If your primary focus is general-purpose jobbing: Seek a flexible batch furnace with reliable thermal controls and, if needed, a basic inert atmosphere capability for process versatility.

Ultimately, a furnace's requirements are a direct reflection of the precision demanded by the process it is built to perform.

Summary Table:

| Requirement Category | Key Features | Primary Goal |

|---|---|---|

| Structural Integrity & Sealing | Exceptional sealing, positive pressure, specialized insulation | Prevent contamination, ensure safety, improve efficiency |

| Precise Thermal Management | Electric/gas heat sources, precise regulation, stable temperature control | Achieve specific metallurgical transformations |

| Atmosphere Control | Inert/reactive gases, water-cooled fans for uniformity, ancillary chambers | Prevent oxidation, enable surface chemistry, ensure part consistency |

| Operational Design | Batch vs. continuous operation, integrated quenching, safety systems | Match throughput needs and process complexity |

Ready to specify the perfect heat treatment furnace for your lab's unique needs?

Whether your priority is high-purity processing for aerospace components, high-volume production for automotive parts, or operational safety with flammable atmospheres, KINTEK has the expertise and equipment to meet your precise requirements. Our range of laboratory furnaces is designed to deliver the structural integrity, thermal management, and atmosphere control your processes demand.

Contact KINTEL today to discuss your application and let our specialists help you achieve consistent, high-quality results.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control