At its core, sintering transforms a fragile, compressed powder into a dense, solid, and mechanically strong object. This is achieved by heating the material to a high temperature, but below its melting point. At this temperature, the individual powder particles begin to fuse together through atomic diffusion, systematically eliminating the empty spaces between them and increasing the overall density and strength of the part.

The fundamental result of sintering is not melting, but rather the atomic-level bonding of particles. This process turns a porous powder shape into a coherent solid, dramatically increasing its density and mechanical integrity.

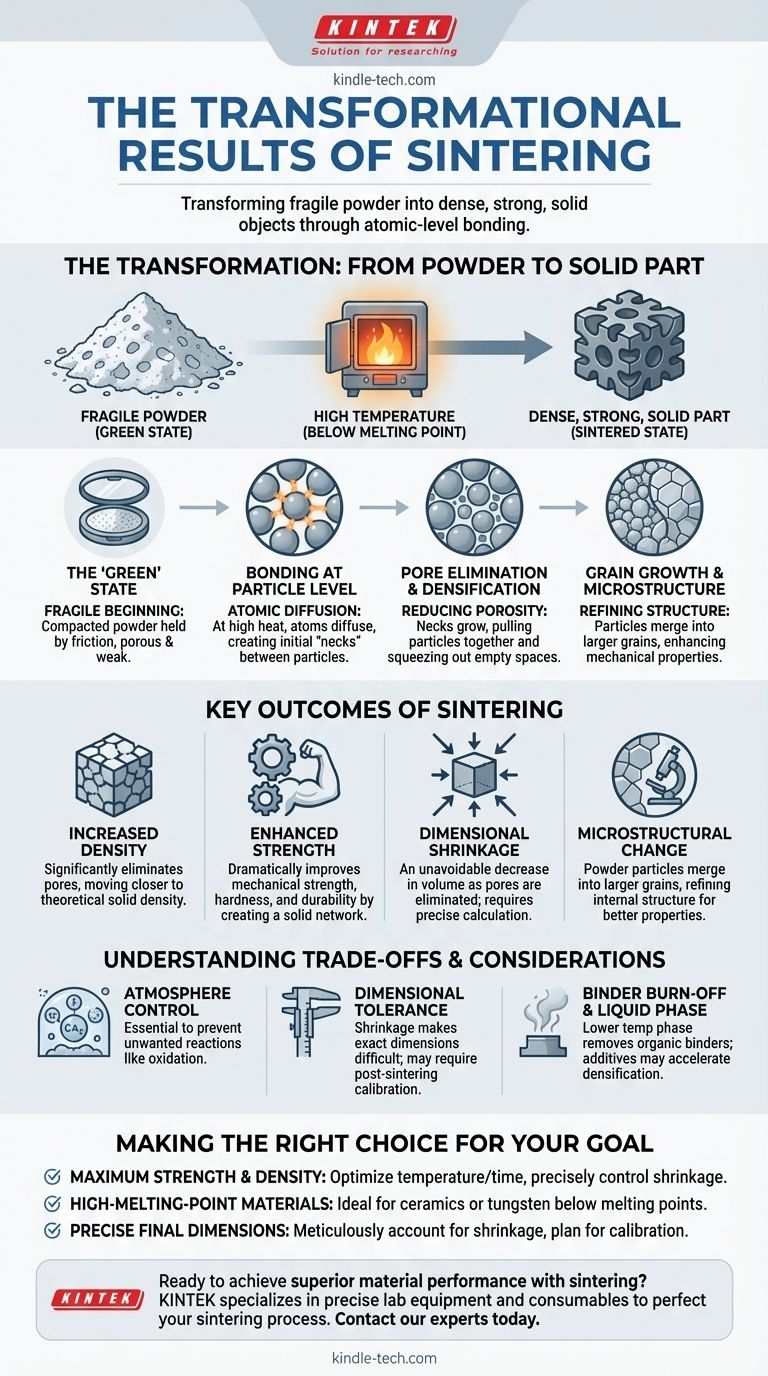

The Transformation: From Powder to a Solid Part

Sintering is a thermal process that fundamentally changes a material's microstructure. It is not a single event but a progression through several stages, each contributing to the final properties of the component.

The "Green" State: A Fragile Beginning

Before sintering, the material exists as a "green" compact. This is simply powder that has been pressed into the desired shape using a die and hydraulic presses.

While it has the correct geometry, the green part is porous and mechanically weak, held together only by the friction between particles.

Bonding at the Particle Level

The crucial transformation occurs when the green compact is heated. At high temperatures, atoms gain enough energy to move, or diffuse, across the boundaries of adjacent particles.

This diffusion creates small "necks" or bonds at every point where particles touch. These initial bonds are the foundation of the final solid object.

Pore Elimination and Densification

As the sintering process continues, these necks grow wider. This growth exerts a powerful force that pulls the centers of the particles closer together.

This action effectively squeezes out the empty spaces, or pores, that existed between the powder particles in the green state. The reduction in porosity directly leads to an increase in the material's density.

Grain Growth and Microstructure

Over time, the original boundaries between individual powder particles disappear as they merge into larger, crystalline structures known as grains.

This process of grain growth refines the internal microstructure of the material, which is a key factor in determining its final mechanical properties, such as hardness and toughness.

Key Outcomes of the Sintering Process

The physical transformations during sintering produce several distinct and desirable results in the final product.

Increased Density

The most direct result of pore elimination is a significant increase in density. A finished sintered part is substantially denser than its initial green compact, moving it closer to the theoretical density of the solid material.

Enhanced Mechanical Strength

By creating a solid, interconnected network of bonded grains, sintering dramatically increases the component's mechanical strength, hardness, and durability. The fragile green compact is transformed into a robust, functional part capable of bearing loads.

Dimensional Shrinkage

A critical and unavoidable consequence of densification is that the part shrinks. As the pores are eliminated and particles pull together, the overall volume of the component decreases. This shrinkage must be precisely calculated and controlled.

Understanding the Trade-offs and Practical Considerations

Achieving a successful sintered part requires controlling several variables and understanding the inherent challenges of the process.

The Need for Atmosphere Control

Sintering is almost always performed in a furnace with a controlled atmosphere. This is essential to prevent unwanted chemical reactions, such as oxidation, which could compromise the material's integrity at high temperatures.

The Challenge of Dimensional Tolerance

Because the part shrinks, achieving exact final dimensions can be difficult. If tight tolerances are required, a post-sintering calibration or sizing step may be necessary, where the part is repressed in a die to correct for any dimensional variations.

Binder Burn-Off

Often, organic binders are mixed with the powder to improve the strength of the green compact. The first stage of heating in the furnace is a lower-temperature burn-off phase to remove these binders before the actual sintering begins.

Liquid Phase Sintering

In some processes, a small amount of an additive with a lower melting point is included in the powder mix. During heating, this additive melts and becomes a liquid phase that flows into the pores, accelerating densification through capillary action.

Making the Right Choice for Your Goal

The specific results of sintering can be tailored by adjusting the process parameters to meet different engineering objectives.

- If your primary focus is maximum strength and density: Your goal is to optimize temperature and time to eliminate as much porosity as possible, which requires precise control over the resulting shrinkage.

- If your primary focus is manufacturing high-melting-point materials: Sintering is the ideal method, as it allows you to create solid parts from materials like ceramics or tungsten at temperatures below their extremely high melting points.

- If your primary focus is achieving precise final dimensions: You must meticulously account for material shrinkage in your initial die design and plan for a potential post-sintering calibration step.

Ultimately, sintering provides a powerful method for converting simple powders into complex, high-performance components with tailored properties.

Summary Table:

| Key Result | Description |

|---|---|

| Increased Density | Eliminates pores, making the part denser and closer to the solid material's theoretical density. |

| Enhanced Strength | Creates a solid, bonded structure, dramatically improving mechanical strength, hardness, and durability. |

| Dimensional Shrinkage | An unavoidable consequence of densification that must be precisely calculated and controlled. |

| Microstructural Change | Powder particles merge into larger grains, refining the internal structure for better properties. |

Ready to achieve superior material performance with sintering?

KINTEK specializes in the precise lab equipment and consumables needed to perfect your sintering process. From high-temperature furnaces with controlled atmospheres to the materials and expertise for achieving your specific density, strength, and dimensional goals, we are your partner in innovation.

Contact our experts today to discuss how we can help you transform powders into high-performance components.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia