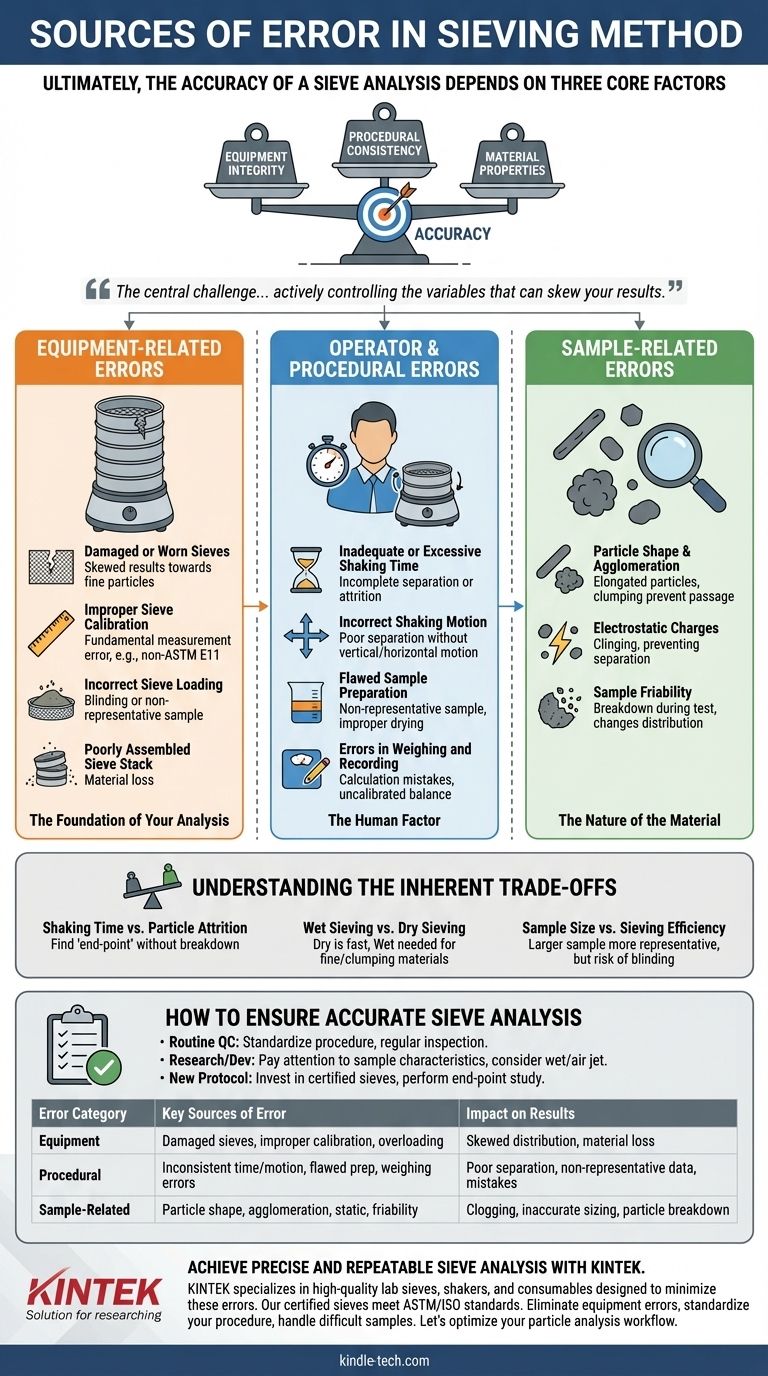

Ultimately, the accuracy of a sieve analysis depends on three core factors: the integrity of your equipment, the consistency of your procedure, and the intrinsic properties of the material being tested. Errors in any one of these areas can cascade, leading to results that are neither accurate nor repeatable.

The central challenge in sieving is not just following a procedure, but actively controlling the variables that can skew your results. True accuracy comes from understanding that errors are rarely random; they are systematic results of issues with your equipment, your technique, or the sample itself.

Equipment-Related Errors: The Foundation of Your Analysis

The physical tools you use are the first potential point of failure. Even a perfect procedure will yield poor results if the equipment is compromised.

Damaged or Worn Sieves

Sieve mesh is delicate. Tears, holes, or significant sagging in the wire cloth will allow oversized particles to pass through, artificially skewing the results toward a finer particle size distribution. Distorted or dented frames can prevent a tight stack, allowing material to be lost.

Improper Sieve Calibration

For regulated industries, using sieves that meet specific standards (like ASTM E11 or ISO 3310-1) is mandatory. Using uncertified or out-of-spec sieves means the aperture openings may not be what you think they are, leading to a fundamental measurement error.

Incorrect Sieve Loading

Overloading a sieve is a common mistake. Too much material on the mesh surface prevents individual particles from having the opportunity to pass through the openings, a phenomenon known as blinding. Conversely, an insufficient sample size may not be statistically representative of the entire batch of material.

Poorly Assembled Sieve Stack

If the sieves are not nested together correctly, or if the lid and pan do not fit snugly, gaps can form. During shaking, fine particles can escape the stack entirely, leading to material loss and inaccurate calculations for the finest fraction.

Operator and Procedural Errors: The Human Factor

How the test is performed is just as critical as the equipment used. Inconsistent technique between different operators or even by the same operator over time is a major source of variability.

Inadequate or Excessive Shaking Time

Sieving requires a specific duration to achieve complete separation. Shaking for too little time results in an incomplete analysis, where coarse particles are left on sieves they should have passed through. Shaking for too long can cause attrition, where brittle particles break down, artificially increasing the amount of fine material.

Incorrect Shaking Motion

Effective sieving requires a combination of a vertical (tapping) motion and a horizontal (circular) motion. The vertical tap helps clear the apertures and lift particles, while the horizontal motion distributes the sample and encourages particles to find an opening. Using a shaker that only provides one motion, or shaking by hand inconsistently, leads to poor separation.

Flawed Sample Preparation

The sample taken for analysis must be representative of the entire bulk material. Improper sampling techniques can lead to a test sample that isn't characteristic of the whole. Furthermore, samples must be properly dried, as moisture can cause fine particles to agglomerate and behave like larger particles.

Errors in Weighing and Recording

This is a straightforward but critical step. Using an uncalibrated or insufficiently precise balance will introduce error into every measurement. Simple human errors, like transcribing numbers incorrectly or mathematical mistakes during calculation, can invalidate an otherwise perfect test.

Sample-Related Errors: The Nature of the Material

Sometimes, the material itself resists accurate analysis. Understanding these properties is key to choosing the right method or adjusting your technique.

Particle Shape and Agglomeration

Sieve analysis assumes roughly spherical particles. Elongated or flaky particles may fail to pass through an aperture they would otherwise fit through if oriented differently. In addition, fine powders can clump together due to moisture or van der Waals forces, preventing them from being sieved as individual particles.

Electrostatic Charges

Very fine, dry powders can develop static electricity during handling and shaking. This causes particles to cling to the sieve mesh and to each other, preventing proper separation and making it difficult to collect and weigh the fractions accurately.

Sample Friability

Friable materials are those that are easily crumbled or broken. The mechanical action of the sieve shaker can cause these particles to break down during the test. This is a significant source of error, as it changes the particle size distribution while the analysis is in progress.

Understanding the Inherent Trade-offs

Perfect sieving is an ideal, and practical application involves balancing competing factors.

Shaking Time vs. Particle Attrition

The goal is to shake just long enough to achieve separation without causing attrition. This "end-point" is often determined by periodically stopping the test and weighing the fractions until the change in weight becomes negligible. For friable materials, this balance is especially delicate.

Wet Sieving vs. Dry Sieving

Dry sieving is faster and simpler. However, for materials with very fine particles (<75 microns) or those prone to agglomeration or static, wet sieving is often necessary. This method eliminates clumping but adds the complexity of washing, filtering, drying, and re-weighing the material.

Sample Size vs. Sieving Efficiency

A larger sample is more representative of the bulk material, but it reduces sieving efficiency by increasing the risk of blinding the mesh. Standards often specify a maximum allowable load per sieve based on its diameter to manage this trade-off.

How to Ensure Accurate Sieve Analysis

Your strategy for minimizing error depends on your objective.

- If your primary focus is routine quality control: Prioritize consistency by standardizing your procedure (shaking time, sample load, shaker settings) and implementing a schedule for regular sieve inspection and cleaning.

- If your primary focus is material research or development: Pay close attention to sample characteristics (friability, static) and perform preliminary tests to determine if you need specialized techniques like wet sieving, air jet sieving, or anti-static measures.

- If your primary focus is establishing a new testing protocol: Invest in certified sieves and perform a methodical end-point determination study to scientifically establish the optimal shaking time for your specific material.

By systematically addressing these variables, you transform sieving from a routine task into a precise analytical method.

Summary Table:

| Error Category | Key Sources of Error | Impact on Results |

|---|---|---|

| Equipment | Damaged sieves, improper calibration, overloading, poor stack assembly | Skewed particle size distribution, material loss |

| Procedural | Inconsistent shaking time/motion, flawed sample prep, weighing errors | Poor separation, non-representative data, calculation mistakes |

| Sample-Related | Particle shape, agglomeration, static charges, friability | Clogging, inaccurate sizing, particle breakdown during test |

Achieve precise and repeatable sieve analysis with KINTEK.

Struggling with inconsistent particle size data? The errors outlined above can compromise your quality control and R&D efforts. KINTEK specializes in high-quality lab sieves, shakers, and consumables designed to minimize these very errors. Our certified sieves meet ASTM/ISO standards, and our equipment ensures consistent, reliable shaking motion and timing.

We help you:

- Eliminate equipment errors with durable, certified sieves and robust sieve shakers.

- Standardize your procedure with reliable equipment that ensures consistent operation every time.

- Handle difficult samples with solutions for wet sieving and static-prone materials.

Let's optimize your particle analysis workflow. Contact our experts today to discuss your specific application and ensure your sieving method delivers the accuracy you need.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What range of particle size does the sieve analysis apply? Master the 25 Micron to 1 mm Standard

- What are three industrial uses for sieving? Ensure Quality and Safety in Your Production Process

- What is the difference between wet sieve analysis and dry sieve analysis? Choose the Right Method for Your Material

- How many types of standard sieves are there? A Guide to ASTM vs. ISO Standards

- What is an example of sieving in the laboratory? Master Particle Size Analysis for Quality Control

- What are the two methods of sieve analysis? Choose the Right Method for Accurate Particle Sizing

- What size are test sieves? A Guide to Frame Diameters and Mesh Sizes

- Why is it important to sieve? Ensure Material Quality and Process Control