At its core, a muffle furnace is a self-contained, high-temperature oven defined by its central design principle: separation. Its key specifications revolve around an inner chamber, or muffle, which isolates the material being heated from the heating elements and any potential contaminants, ensuring a clean, uniform, and precisely controlled thermal environment.

A muffle furnace is not just about reaching high temperatures; its fundamental value lies in creating a chemically isolated and thermally uniform environment. This is achieved by separating the sample chamber from the heat source, preventing contamination and ensuring predictable results.

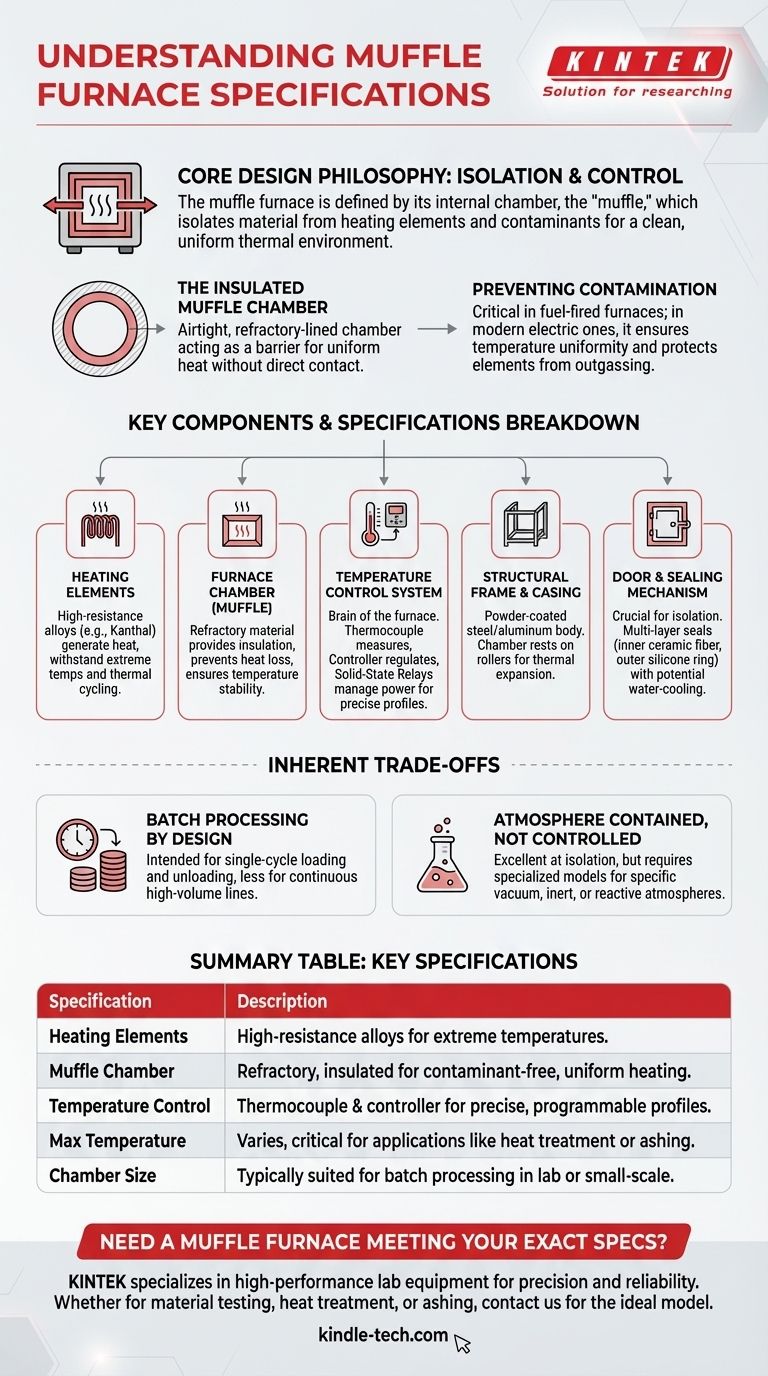

The Core Design Philosophy: Isolation and Control

The primary specification that defines a muffle furnace is its unique internal structure. Unlike a simple oven, it is designed to protect the workpiece from external influences during heating.

The Insulated Muffle Chamber

The "muffle" is an airtight, insulated chamber made of refractory materials. This is where the sample or workpiece is placed.

Its purpose is to act as a barrier, ensuring the heat treats the material uniformly without direct contact with the heating elements.

Preventing Contamination

In traditional fuel-fired furnaces, this design is critical. It prevents byproducts of combustion, like soot or gases, from reacting with and contaminating the material being heated.

The Modern Electric Advantage

Modern muffle furnaces primarily use electric heating elements. While this eliminates combustion byproducts entirely, the muffle design remains crucial for ensuring exceptional temperature uniformity and protecting the elements from any outgassing from the workpiece.

A Breakdown of Key Components and Specifications

The overall performance of a muffle furnace is a direct result of the quality and integration of its core components.

Heating Elements

These are responsible for generating the heat. They are typically made from high-resistance alloys like iron-chromium-aluminum (e.g., Kanthal) that can withstand extreme temperatures and repeated thermal cycling.

The Furnace Chamber (Muffle)

The chamber itself is built from heat-resistant, refractory materials. This lining provides excellent insulation, preventing heat loss and contributing to energy efficiency and temperature stability.

Temperature Control System

This is the furnace's brain. It consists of a thermocouple to measure the internal temperature, a temperature controller to set and regulate it, and solid-state relays to manage power delivery to the heating elements. This system allows for precise control over heating profiles.

Structural Frame and Casing

The outer body is typically made of powder-coated steel or aluminum. The chamber and frame are often separate, with the inner chamber resting on rollers to allow for thermal expansion and contraction without stressing the overall structure.

Door and Sealing Mechanism

The door is a critical component for maintaining the isolated environment. High-quality furnaces feature multi-layer seals, often using an inner ceramic fiber rope and an outer silicone ring. Some may include a water-cooling jacket to protect the seal's integrity and lifespan.

Understanding the Inherent Trade-offs

While highly effective, the design of a muffle furnace presents certain operational considerations and limitations.

Batch Processing by Design

The classic box-shaped design with a single door is intended for batch processing. Materials are loaded, heated through a specific cycle, and then unloaded. This is less suitable for continuous, high-volume production lines.

Atmosphere is Contained, Not Controlled

A standard muffle furnace excels at isolating a sample from the outside environment. However, it does not inherently control the atmosphere inside the chamber. Specialized models are required for processes that need a specific vacuum, inert gas, or reactive gas atmosphere.

Capacity and Size

The self-contained, heavily insulated design often lends itself to laboratory or small-scale production sizes. While large industrial muffle furnaces exist, the design is most common in applications where precision is more critical than sheer volume.

Making the Right Choice for Your Application

Selecting the right specifications depends entirely on your intended use.

- If your primary focus is precise laboratory analysis or material testing: Prioritize exceptional temperature uniformity and a sophisticated, programmable temperature controller.

- If your primary focus is small-scale metal heat treatment (e.g., hardening, annealing): Focus on a robust chamber construction, a high maximum temperature, and rapid heating capabilities.

- If your primary focus is general heating or ashing: Look for a balance of energy efficiency, ease of maintenance, and durability in the heating elements and insulation.

Ultimately, understanding that a muffle furnace is a tool for contaminant-free, uniform heating is the key to selecting the specifications that match your goal.

Summary Table:

| Key Specification | Description |

|---|---|

| Heating Elements | High-resistance alloys (e.g., Kanthal) for extreme temperatures. |

| Muffle Chamber | Refractory, insulated chamber for contaminant-free, uniform heating. |

| Temperature Control | Thermocouple and controller for precise, programmable heating profiles. |

| Max Temperature | Varies by model; critical for applications like heat treatment or ashing. |

| Chamber Size | Typically suited for batch processing in lab or small-scale production. |

Need a muffle furnace that meets your exact specifications? At KINTEK, we specialize in high-performance lab equipment designed for precision and reliability. Whether you're conducting material testing, heat treatment, or ashing applications, our experts will help you select the ideal model with the right temperature range, chamber size, and control features for your laboratory.

Contact our team today for a personalized consultation and discover how KINTEK's solutions can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the working principles of furnace? A Guide to Combustion, Resistance, and Induction Heating

- What is a muffle furnace used for in a lab? Achieve Clean, High-Temperature Processing

- How do you cool down a muffle furnace? Ensure Longevity and Safety with the Correct Procedure

- What are the uses of muffle furnace in pharmaceutical industry? Essential for Drug Purity & Safety

- What is the working principle of a muffle furnace? Achieve Precise, Contamination-Free Heating