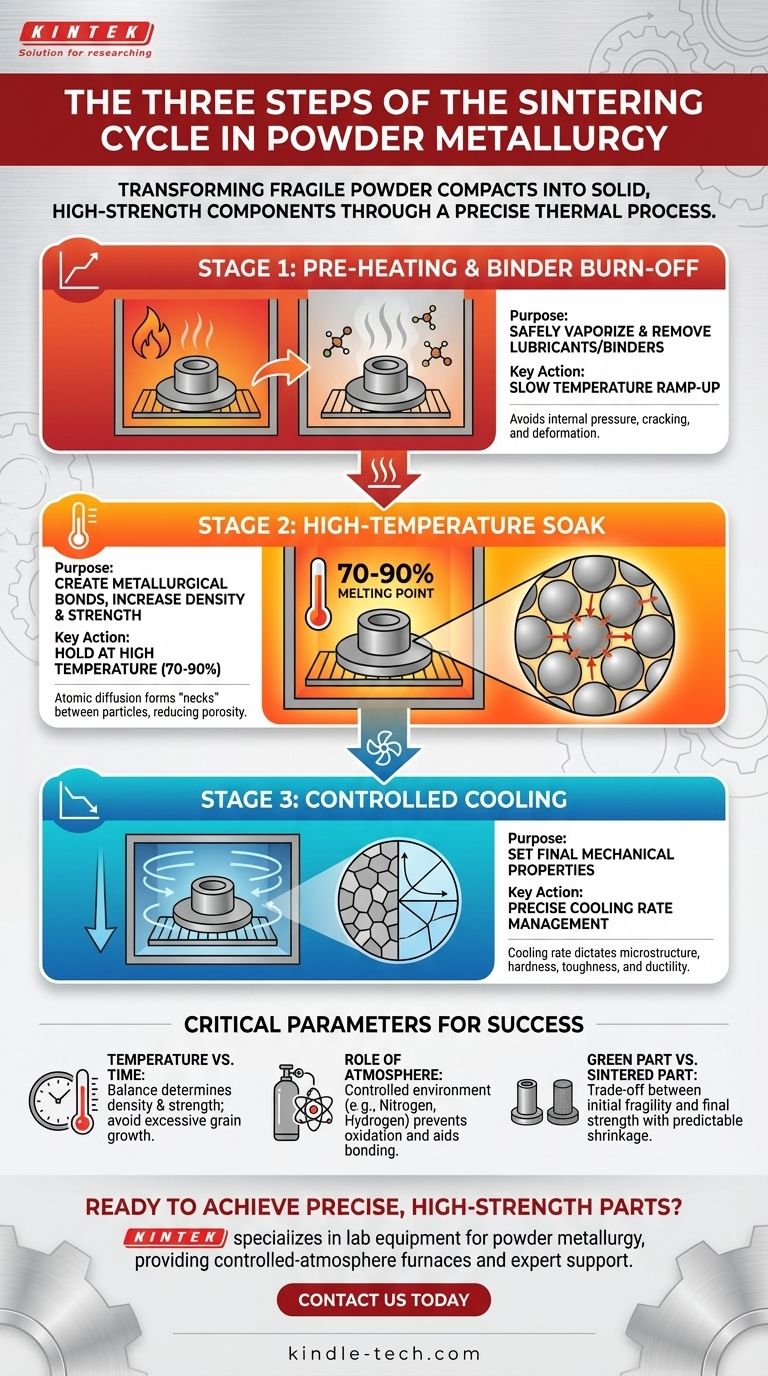

The three distinct stages of a sintering cycle are the initial heating and binder burn-off, the high-temperature soak where particles bond, and the controlled cooling phase that sets the final material properties. While often confused with the broader powder metallurgy process, the sintering cycle refers specifically to this three-part heat treatment that transforms a fragile powder compact into a solid, high-strength component.

The critical distinction to understand is that "sintering" is not a single action but a precise, three-stage thermal process. Each stage—heating, soaking, and cooling—serves a unique purpose in transforming loose metal powder into a unified, functional part.

Why Sintering is the Decisive Step

Before a part enters the sintering furnace, it's just a collection of metal powders pressed into a shape. This is known as a "green compact." It's fragile and has no significant structural strength.

The sintering process is the heat treatment that gives the part its strength and integrity. By heating it to a temperature just below the melting point of the primary metal, you trigger a process of atomic diffusion.

Think of it like individual ice cubes in a glass. Even without melting, where they touch, they begin to fuse and bond together. Sintering does the same for metal particles, creating strong metallurgical bonds that turn the powder into a solid mass.

The Three Stages of the Sintering Cycle Explained

The success of a sintered part depends entirely on the precise control of the furnace's temperature profile over time. This profile is broken down into three essential stages.

Stage 1: Pre-heating and Binder Burn-off

The first phase involves slowly ramping up the temperature. This isn't just about getting the part hot.

Its primary purpose is to safely vaporize and remove any lubricants or binders that were mixed with the metal powder during the compaction stage. Rushing this step can cause these additives to boil, creating internal pressure that can crack or deform the part.

Stage 2: High-Temperature Soaking

This is the core of the sintering process. The component is held at a specific, high temperature—typically 70-90% of the metal's melting point—for a set period.

During this soak, atomic diffusion goes into high gear. Atoms migrate across the boundaries of adjacent particles, creating strong metallurgical bonds and "necks" between them. This process reduces the empty space (porosity) in the part, increasing its density and strength.

Stage 3: Controlled Cooling

The final stage is the controlled cooling of the part back to room temperature. The cooling rate is not an afterthought; it is a critical step that dictates the final microstructure of the metal.

Much like quenching or tempering steel, a fast or slow cooling rate can dramatically alter properties like hardness, toughness, and ductility. This stage is engineered to lock in the desired mechanical characteristics for the component's final application.

Understanding the Critical Parameters

Achieving a successful outcome requires balancing several factors. Mismanaging these can lead to failed parts or inconsistent quality.

Temperature vs. Time

The combination of soaking temperature and time determines the final density and strength. Higher temperatures or longer times can increase bonding but also risk excessive grain growth or part distortion. This balance is key to achieving the desired specifications without unwanted side effects.

The Role of Atmosphere

Sintering is almost always done in a controlled-atmosphere furnace. Heating metal to such high temperatures in the presence of oxygen would cause immediate and catastrophic oxidation (rusting), ruining the part.

Furnaces are typically filled with inert or reducing gases, like nitrogen or a hydrogen blend, to protect the components and facilitate clean particle bonding.

Green Part vs. Sintered Part

There is an inherent trade-off between the pre-sintered and post-sintered states. The "green" part is dimensionally very close to the mold it was pressed in, but it is extremely fragile. The final sintered part is strong and durable, but it will have undergone some predictable shrinkage as its density increased.

Matching the Cycle to Your Goal

The specific parameters of the three-stage cycle are adjusted based on the material and the desired outcome.

- If your primary focus is maximum strength and density: The high-temperature soak (Stage 2) will be optimized with higher temperatures or longer hold times.

- If your primary focus is high dimensional accuracy: All three stages must be meticulously controlled to manage thermal expansion and shrinkage predictably.

- If you are creating a heat-treated part: The controlled cooling (Stage 3) is the most critical phase, as its rate will determine the final hardness and microstructure.

Mastering these three stages is the key to reliably converting simple metal powder into a precise, high-performance component.

Summary Table:

| Stage | Purpose | Key Action |

|---|---|---|

| 1. Pre-heating & Burn-off | Safely remove lubricants/binders | Slow temperature ramp-up |

| 2. High-Temperature Soak | Create particle bonds & increase density | Hold at 70-90% of melting point |

| 3. Controlled Cooling | Set final mechanical properties | Precise cooling rate management |

Ready to achieve precise, high-strength sintered parts?

KINTEK specializes in lab equipment and consumables for powder metallurgy, providing the controlled-atmosphere furnaces and expert support you need to master each stage of the sintering cycle—from binder burn-off to final cooling.

Contact us today to discuss how our solutions can enhance your lab's efficiency and ensure consistent, high-quality results for your metal components.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vertical Laboratory Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- What is the process of a vacuum furnace? Achieve Superior Material Purity and Performance

- What is vacuum hardening? Achieve Superior Surface Quality and Hardness

- What are the dangers of pyrolysis? Managing Environmental, Operational, and Chemical Risks

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- How does the discharge effect of a DC pulse power supply affect SPS nickel-based alloys? Achieve Rapid Densification

- Can stainless steel be brazed? Yes, with the right techniques to overcome chromium oxide

- What is the concept of quenching? Master the Rapid Cooling Process for Stronger Metals

- What role do dynamic vacuum heat treatment furnaces play in enhancing Inconel 718? Unlock Superior Alloy Performance