In metallurgy, the two principal types of annealing are full annealing and process annealing. While both aim to soften a metal and improve its ductility, they differ significantly in the temperature used and the final microstructure achieved. Full annealing completely resets the material to its softest possible state, whereas process annealing is a more targeted, intermediate treatment used to enable further work.

The fundamental choice is not just about which type of annealing to use, but about understanding your ultimate goal. You must decide if you need the absolute maximum softness for a critical forming operation (full annealing) or simply enough workability to continue a manufacturing process (process annealing).

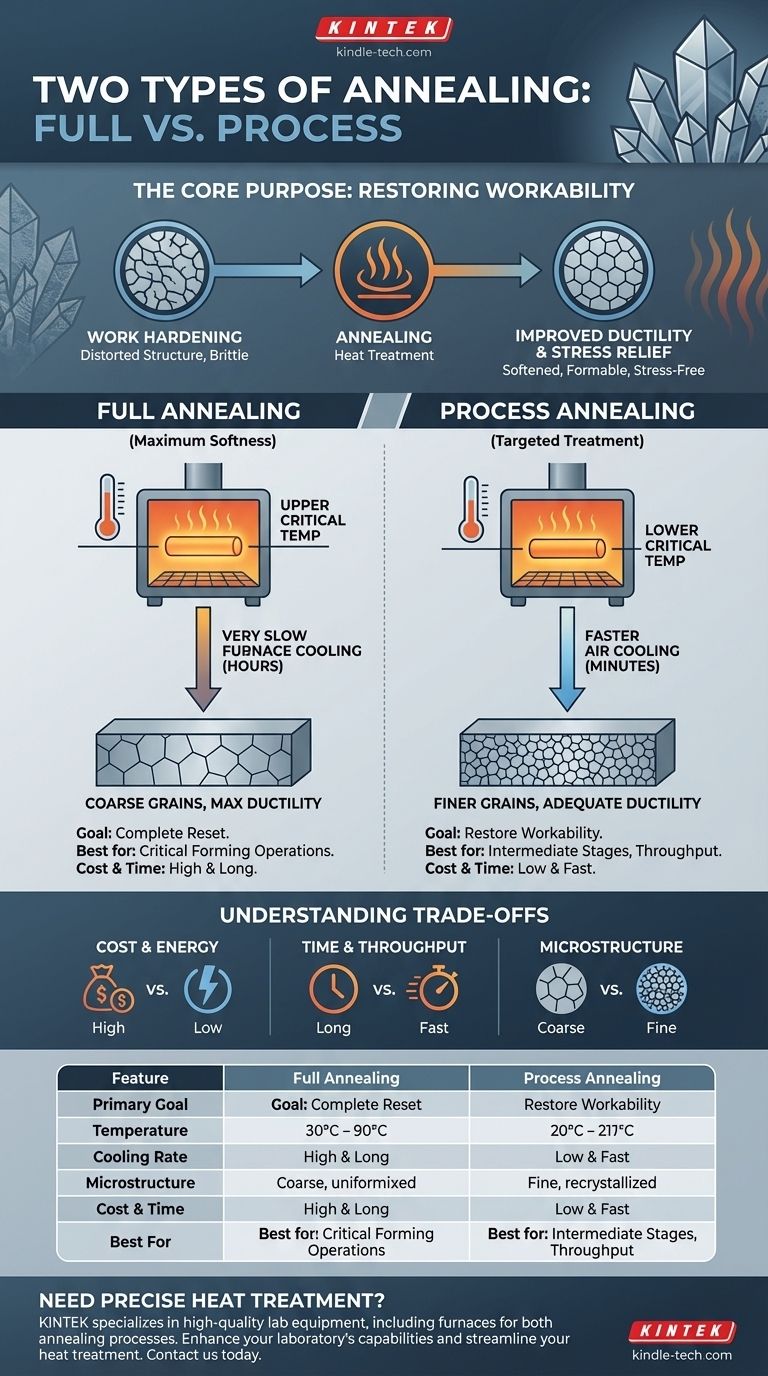

The Core Purpose of Annealing: Restoring Workability

Before comparing the methods, it's crucial to understand why annealing is necessary. Manufacturing processes fundamentally alter a metal's internal structure, and annealing is the primary tool used to reverse these changes.

Reversing Work Hardening

When a metal is bent, drawn, or cold-formed, its internal crystal structure (grains) becomes distorted and strained. This effect, known as work hardening, makes the material stronger and harder but also significantly less ductile and more brittle.

Improving Ductility and Formability

Annealing restores ductility, which is the ability of a material to deform without fracturing. By making the material softer and more ductile, it permits further forming operations that would otherwise cause the workpiece to crack.

Relieving Internal Stresses

Processes like welding or casting can introduce significant internal stresses as the material cools unevenly. These locked-in stresses can lead to premature failure or warping over time. Annealing allows the metal's internal structure to relax, effectively neutralizing these hidden stresses.

A Closer Look at the Two Primary Methods

The choice between full and process annealing comes down to the required temperature, time, and the specific material properties you need to achieve.

Full Annealing: The Complete Reset

Full annealing is designed to produce the softest, most ductile state a metal can achieve.

The process involves heating the metal above its upper critical temperature, holding it there long enough for the internal structure to fully transform, and then cooling it down extremely slowly, often by leaving it inside the turned-off furnace. This creates a uniform and stress-free grain structure, maximizing softness.

Process Annealing: The Targeted Treatment

Process annealing (also known as intermediate or subcritical annealing) is a more pragmatic and common approach used between different stages of cold working.

Here, the metal is heated to a temperature below its lower critical temperature. This is just hot enough to allow for recrystallization—the formation of new, strain-free grains—but not hot enough to cause the complete structural transformation seen in full annealing. Cooling can be done more quickly, typically in still air.

Understanding the Trade-offs

Choosing the right annealing method is a balance of metallurgical requirements, cost, and production time.

Desired Properties vs. Cost

Full annealing produces the best possible ductility and softness, but the high temperatures and extremely long, slow cooling cycles make it the most energy-intensive and expensive option.

Process annealing doesn't achieve maximum softness, but it restores enough ductility for most subsequent forming operations at a fraction of the time and cost.

Time and Throughput

The slow furnace cooling required for full annealing can take many hours, creating a significant bottleneck in a production environment.

The faster heating and air-cooling of process annealing allow for much higher throughput, making it ideal for multi-stage manufacturing where parts need to be softened between steps.

Impact on Final Microstructure

Full annealing fundamentally changes the metal's phase and creates a coarse grain structure, which is ideal for ductility but may not be desirable for final strength.

Process annealing primarily recrystallizes the existing structure without a phase change, providing a finer grain structure that relieves stress while retaining more hardness than a fully annealed part.

Making the Right Choice for Your Goal

Your specific objective dictates which annealing process is the appropriate engineering choice.

- If your primary focus is maximum softness and machinability for a difficult forming operation: Full annealing is the correct choice to completely reset the material's properties.

- If your primary focus is restoring enough ductility to continue with another stage of cold work: Process annealing is the faster, more economical solution.

- If your primary focus is simply removing internal stresses from a welded or cast part: A specific type of subcritical treatment, stress-relief annealing, is the most efficient method.

Ultimately, selecting the correct heat treatment is about precisely controlling the material's internal structure to achieve the desired performance.

Summary Table:

| Feature | Full Annealing | Process Annealing |

|---|---|---|

| Primary Goal | Maximum softness & ductility | Restore workability for further processing |

| Temperature | Heated above upper critical temperature | Heated below lower critical temperature |

| Cooling Rate | Very slow (furnace cooling) | Faster (air cooling) |

| Microstructure | Coarse, uniform grains | Finer, recrystallized grains |

| Cost & Time | Higher cost, longer process | Lower cost, faster throughput |

| Best For | Critical forming operations, complete reset | Intermediate stages, stress relief |

Need precise heat treatment for your materials?

Choosing the right annealing process is critical for achieving the desired material properties in your lab or production line. At KINTEK, we specialize in providing high-quality lab equipment, including furnaces perfect for both full and process annealing. Our experts can help you select the right tools to ensure optimal ductility, stress relief, and efficiency for your specific metals and alloys.

Contact us today using the form below to discuss your annealing needs and discover how KINTEK's solutions can enhance your laboratory's capabilities and streamline your heat treatment processes.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- Can you braze two different metals? Yes, and here’s how to do it successfully.

- What is the major advantage that brazing has over welding? Joining Dissimilar Metals with Ease

- Which element made stainless steel difficult to brazed? It's Chromium's Oxide Layer