At its core, sintering is a thermal process that transforms a powder compact into a dense, solid mass without melting it completely. The primary types of sintering are distinguished by their underlying physical mechanism—such as solid-state, liquid-phase, or reactive sintering—and the specific technology used to apply heat and pressure, including conventional furnace heating, microwaves, spark plasma, or hot isostatic pressing.

Sintering is not a single process, but a family of techniques. Understanding the difference between the core mechanisms (how particles bond) and the technologies (how energy is delivered) is the key to selecting the right method for your material and desired outcome.

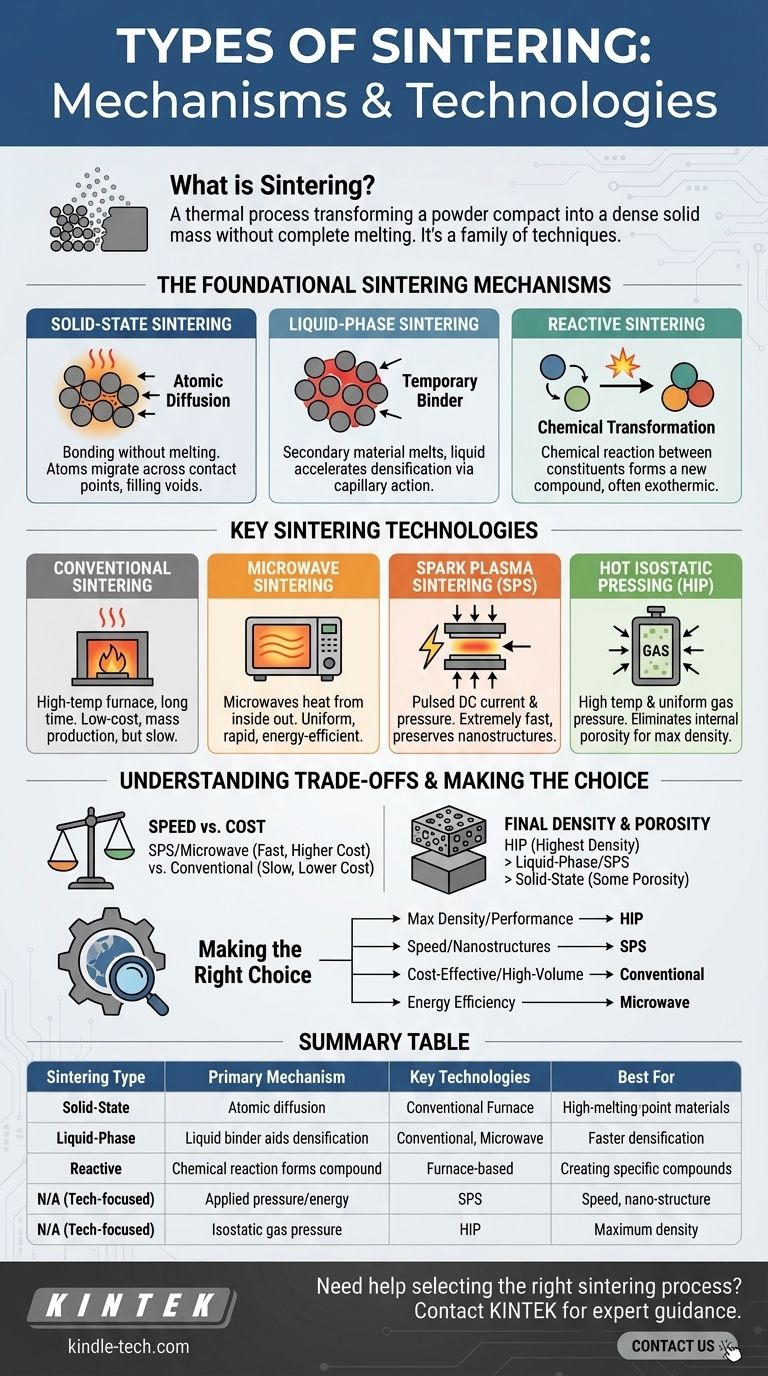

The Foundational Sintering Mechanisms

Before exploring specific technologies, it's critical to understand the fundamental ways particles can be bonded together. The choice of mechanism is dictated by the material itself and the desired final properties.

Solid-State Sintering: Bonding Without Melting

Solid-state sintering is the most classic form. Powdered material is heated to a temperature just below its melting point.

At this elevated temperature, atoms at the contact points between particles become mobile and diffuse across the particle boundaries. This atomic migration gradually fills the voids (pores) between particles, causing them to fuse and the overall part to shrink and densify.

This method is essential for materials with extremely high melting points, where complete melting would be impractical or energetically expensive.

Liquid-Phase Sintering: Using a Temporary Binder

In liquid-phase sintering, a small amount of a secondary material with a lower melting point is mixed with the primary powder.

When heated, this secondary material melts and becomes a liquid phase that wets the solid primary particles. This liquid accelerates densification by pulling particles together through capillary action and providing a fast path for atomic diffusion. The liquid is often driven off or incorporated into the final structure.

This process generally leads to lower porosity and faster densification compared to solid-state sintering.

Reactive Sintering: A Chemical Transformation

Reactive sintering, or reaction bonding, involves a chemical reaction between two or more different powder constituents during heating.

The initial powders react to form a new, desired chemical compound. The heat generated by this exothermic reaction can often assist the sintering process, leading to the formation of a dense final product made of the new material.

Key Sintering Technologies

The mechanisms above are enabled by different technologies that deliver heat and, in some cases, pressure. The technology choice dramatically impacts speed, cost, and the final properties of the component.

Conventional Sintering: The Baseline

This involves placing the powder compact in a high-temperature furnace and heating it for an extended period. It is a well-understood and relatively low-cost method for mass production.

However, it is slow, energy-intensive, and may result in undesirable grain growth, which can negatively impact mechanical properties.

Microwave Sintering: Heating from the Inside Out

This advanced method uses microwave radiation to heat the material. Unlike a conventional furnace which heats from the outside in, microwaves can heat the entire volume of the material more uniformly and rapidly.

This results in significantly shorter processing times, reduced energy consumption, and often a finer, more desirable final microstructure.

Spark Plasma Sintering (SPS): Speed and Direct Current

SPS, also known as Field Assisted Sintering Technology (FAST), simultaneously applies high mechanical pressure and a pulsed DC electrical current to the powder.

The current generates rapid resistive heating at the particle contact points, while the pressure aids in consolidation. This is an extremely fast process, often reducing sintering times from hours to minutes, which is excellent for preserving nano-scale microstructures.

Hot Isostatic Pressing (HIP): Uniform Density

In HIP, the component is subjected to both high temperature and high-pressure inert gas from all directions. This isostatic (uniform) pressure is highly effective at closing internal porosity.

HIP is often used as a secondary step after conventional sintering to eliminate residual voids and achieve nearly 100% density, which is critical for high-performance applications in aerospace or medical implants. It can also be used as a primary process to sinter powders directly.

Understanding the Trade-offs

No single sintering method is universally superior. The optimal choice depends on a balance of speed, cost, desired final density, and material constraints.

Speed vs. Cost

Advanced methods like SPS and Microwave Sintering are significantly faster but require more complex and expensive equipment. Conventional sintering is slower but uses more affordable, established technology suitable for large-scale production.

Final Density and Porosity

For applications demanding the highest possible density and minimal porosity, HIP is the gold standard. Liquid-phase sintering and SPS can also achieve very high densities, while conventional solid-state sintering may leave some residual porosity.

Material and Geometric Limitations

Reactive sintering is limited to material systems that can undergo a suitable chemical reaction. Microwave sintering is most effective on materials that couple well with microwaves. The complexity and size of parts can also be a constraint for methods like SPS that rely on a die.

Making the Right Choice for Your Goal

Your application's primary driver should guide your selection of a sintering process.

- If your primary focus is maximum density and performance: Hot Isostatic Pressing (HIP) is the most reliable choice, especially for critical components.

- If your primary focus is processing speed and preserving nanostructures: Spark Plasma Sintering (SPS) is unmatched in its ability to densify materials in minutes.

- If your primary focus is cost-effective, high-volume production: Conventional furnace sintering, often combined with a liquid-phase mechanism, remains the industry workhorse.

- If your primary focus is energy efficiency and rapid heating: Microwave sintering offers a compelling alternative to conventional methods for suitable materials.

Ultimately, selecting the correct sintering process empowers you to engineer materials with precisely the properties your design demands.

Summary Table:

| Sintering Type | Primary Mechanism | Key Technologies | Best For |

|---|---|---|---|

| Solid-State | Atomic diffusion below melting point | Conventional Furnace | High-melting-point materials |

| Liquid-Phase | Liquid binder aids densification | Conventional, Microwave | Faster densification, lower porosity |

| Reactive | Chemical reaction forms new compound | Furnace-based | Creating specific compound materials |

| N/A (Technology-focused) | Applied pressure/energy | Spark Plasma Sintering (SPS) | Speed, nano-structure preservation |

| N/A (Technology-focused) | Isostatic gas pressure | Hot Isostatic Pressing (HIP) | Maximum density, critical components |

Need help selecting the right sintering process for your lab's materials? KINTEK specializes in lab equipment and consumables, offering expert guidance and solutions tailored to your sintering needs—whether you're working with solid-state, liquid-phase, or advanced methods like SPS or HIP. Let us help you achieve precise material properties and optimize your research or production. Contact our team today to discuss your requirements!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What is a laboratory mixer? A Guide to Achieving Perfect Sample Homogeneity

- How does a 3 stage furnace work? Achieve Superior Comfort and Efficiency

- Why is an ultrasonic homogenizer used for LNMO samples? Ensure Accurate Particle Size Distribution Analysis

- What is the function of magnetic stirring equipment? Achieve Perfect TiAl Slurry Homogeneity

- What is the mechanism of SPS? Unlock Rapid, Low-Temperature Densification

- What is the most common source of heat used for brazing? Torch Brazing Explained for Optimal Joints

- How much does it cost to make a lab grown diamond? The True Price of High-Tech Gem Creation

- How to start a lab grown diamond business? Choose the Right Model for Success