At its core, a sintering furnace is categorized by its heating method, how it moves material, and the specific process environment it creates. The most common distinctions are between resistance and induction furnaces for heating, and between pusher and walking-beam furnaces for material transport, though highly specialized systems like vacuum or spark plasma furnaces also exist for specific applications.

Understanding the types of sintering furnaces is not about memorizing a list. It is about recognizing that each design represents a different solution for balancing cost, speed, material properties, and production scale. The right choice depends entirely on the technical requirements of your material and your operational goals.

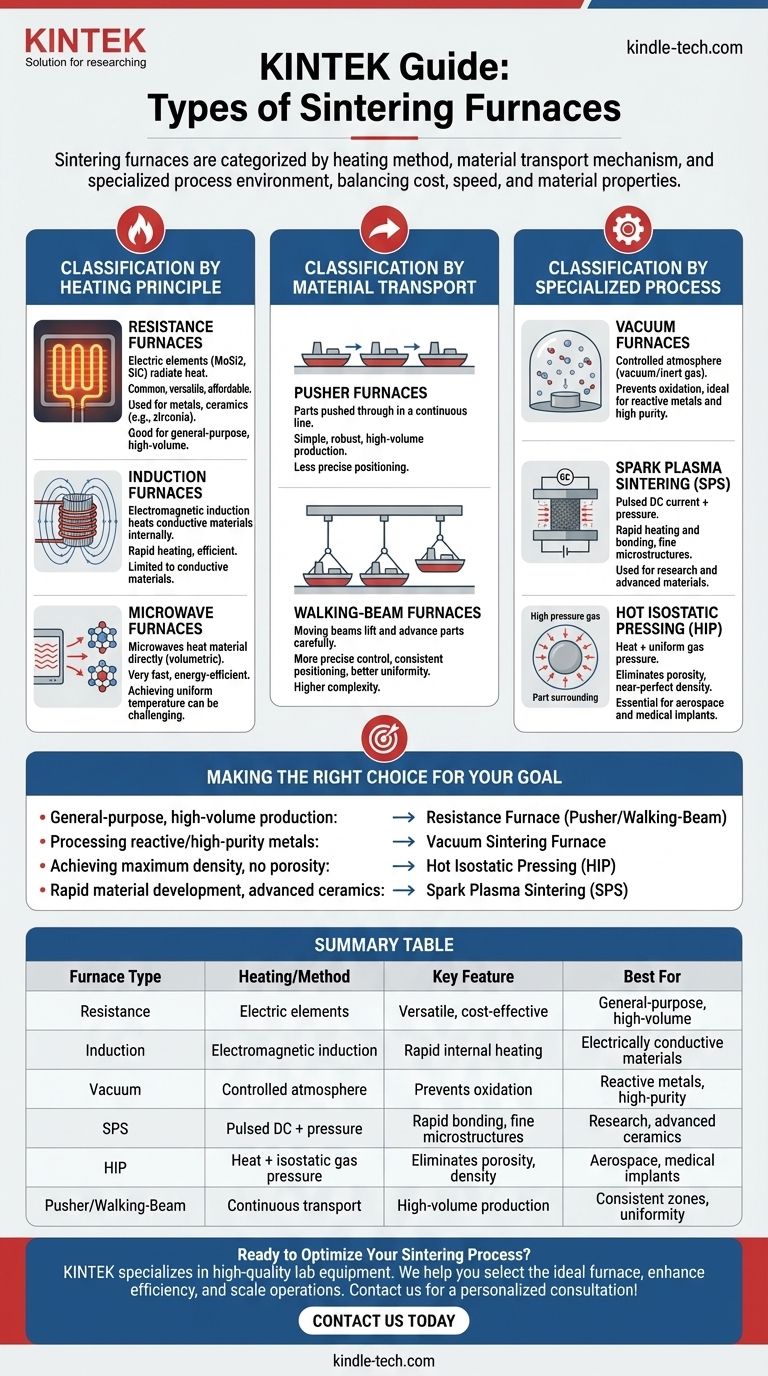

Classification by Heating Principle

The fundamental role of the furnace is to generate and control heat. The method it uses to do this is the most basic way to classify it.

Resistance Furnaces

A resistance furnace is the most common and versatile type. It functions much like a conventional oven, using electric heating elements to generate heat through electrical resistance.

These elements, often made of materials like molybdenum disilicide (MoSi2) or silicon carbide (SiC), radiate heat to raise the temperature of the furnace chamber and the parts within it. They are the workhorses of the industry, used for a vast range of metals and ceramics like zirconia.

Induction Furnaces

An induction furnace uses the principle of electromagnetic induction. A powerful alternating current is passed through a coil, creating a fluctuating magnetic field around the part.

This magnetic field induces electrical currents (eddy currents) directly within the conductive material, causing it to heat up rapidly from the inside out. This method is highly efficient but is generally limited to sintering electrically conductive materials.

Microwave Furnaces

A newer approach, microwave sintering, uses microwave energy to heat the material. Instead of heating the furnace chamber, the microwaves directly couple with the material's molecules, causing rapid and volumetric heating.

This can significantly reduce sintering time and energy consumption, but achieving uniform temperature distribution can be more challenging than with traditional resistance heating.

Classification by Material Transport

For continuous production, the mechanism for moving parts through the furnace's heat zones is a critical design feature.

Pusher Furnaces

In a pusher furnace, parts are loaded onto ceramic plates or "boats." A pusher mechanism at the entrance then pushes the entire train of boats through the furnace in a continuous line.

This is a simple and robust method suitable for high-volume production where slight variations in positioning are acceptable.

Walking-Beam Furnaces

A walking-beam furnace offers more precise control. It uses a set of moving beams that lift the boats, move them forward a set distance, and then lower them back onto a stationary hearth.

Think of it as carefully "walking" the parts through the furnace. This mechanism prevents the parts from bumping into each other and ensures more consistent positioning within the thermal zones, leading to higher process uniformity.

Classification by Specialized Process

Some applications require environments that go beyond simple heating. This has led to highly specialized furnace designs.

Vacuum Furnaces

A vacuum sintering furnace is designed to operate with a controlled atmosphere, either a high vacuum or a specific inert gas. This is critical for preventing oxidation when working with reactive metals or for processes where atmospheric purity is paramount. They come in both vertical and horizontal configurations depending on the part geometry and loading requirements.

Spark Plasma Sintering (SPS)

An SPS furnace combines heat with mechanical pressure. It sends powerful pulses of direct current (DC) through the powdered material while simultaneously compressing it in a die.

This process generates sparks between powder particles, cleaning their surfaces and promoting extremely rapid heating and bonding. It is primarily used in research and for producing advanced materials with fine-grained microstructures.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing is a process used to achieve near-perfect density in critical components. In a HIP furnace, parts are heated to a high temperature while being subjected to immense, uniform gas pressure from all directions.

This combination of heat and isostatic pressure collapses any internal voids or porosity, making it essential for high-performance applications in industries like aerospace and medical implants.

Understanding the Trade-offs

Choosing a furnace involves balancing competing priorities. There is no single "best" type; there is only the best fit for your application.

Cost vs. Performance

Standard resistance furnaces are the most common and generally most affordable option for general-purpose production. Specialized systems like HIP or SPS furnaces represent a significant capital investment but deliver superior material properties that are impossible to achieve otherwise.

Speed vs. Uniformity

Microwave sintering offers the potential for incredible speed, but can risk thermal gradients or "hot spots." In continuous furnaces, a walking-beam mechanism provides better thermal uniformity and process control than a simpler pusher design, but at a higher mechanical complexity.

Material Compatibility

Your material dictates the technology. Induction heating is ineffective for non-conductive materials like many ceramics. Sintering reactive metals like titanium absolutely requires a vacuum furnace to prevent contamination and embrittlement.

Making the Right Choice for Your Goal

Select your furnace based on the specific outcome you need to achieve.

- If your primary focus is general-purpose, high-volume production: A continuous resistance furnace, either pusher or walking-beam, is the industry standard for materials like stainless steel and zirconia.

- If your primary focus is processing reactive or high-purity metals: A vacuum sintering furnace is non-negotiable to control the atmosphere and prevent oxidation.

- If your primary focus is achieving maximum density and eliminating all porosity: Hot Isostatic Pressing (HIP) is the definitive solution for mission-critical components.

- If your primary focus is rapid material development or advanced ceramics: A Spark Plasma Sintering (SPS) furnace provides unmatched speed for densifying novel powders.

Ultimately, the furnace is a tool, and selecting the right one is a strategic decision that directly impacts the quality, cost, and performance of your final product.

Summary Table:

| Furnace Type | Heating/Method | Key Feature | Best For |

|---|---|---|---|

| Resistance Furnace | Electric elements | Versatile, cost-effective | General-purpose, high-volume production (e.g., stainless steel, zirconia) |

| Induction Furnace | Electromagnetic induction | Rapid internal heating | Electrically conductive materials |

| Vacuum Furnace | Controlled atmosphere (vacuum/inert gas) | Prevents oxidation | Reactive metals, high-purity processes |

| Spark Plasma Sintering (SPS) | Pulsed DC current + pressure | Rapid bonding, fine microstructures | Research, advanced ceramics |

| Hot Isostatic Pressing (HIP) | Heat + isostatic gas pressure | Eliminates porosity, near-perfect density | Aerospace, medical implants |

| Pusher/Walking-Beam | Continuous material transport | High-volume production | Consistent thermal zones, process uniformity |

Ready to Optimize Your Sintering Process?

Choosing the right sintering furnace is critical to achieving your material performance and production goals. At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your specific sintering needs.

We help you:

- Select the ideal furnace based on your material, volume, and quality requirements.

- Enhance efficiency with reliable, precision-engineered equipment.

- Scale your operations with solutions for both R&D and high-volume production.

Whether you're working with metals, ceramics, or advanced composites, KINTEK has the expertise and equipment to support your success.

Contact us today for a personalized consultation and let’s build the perfect sintering solution for your lab!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What is the most crucial part in ash content determination? The Key to Accurate, Repeatable Results

- What are the primary functions of a high-temperature box furnace in LLZT synthesis? Maximize Battery Research Results

- What role does a high-temperature furnace play in the preparation of ceramic-enamel glass? Achieve Permanent Fusion

- What is the objective of tempering in heat treatment? Achieve the Perfect Balance of Hardness and Toughness

- What is the role of high-temperature muffle furnaces in the synthesis of NASICON-structured LATP ceramic powder?

- Why is a box-type high-temperature resistance furnace used for T-POMs@ZIF-67? Master MOF-to-Catalyst Pyrolysis

- What are the disadvantages of wet ashing? Key Safety & Contamination Risks

- What is the critical function of a high-temperature furnace in MEC carbon brush preparation? Optimize Bio-Anode Surface