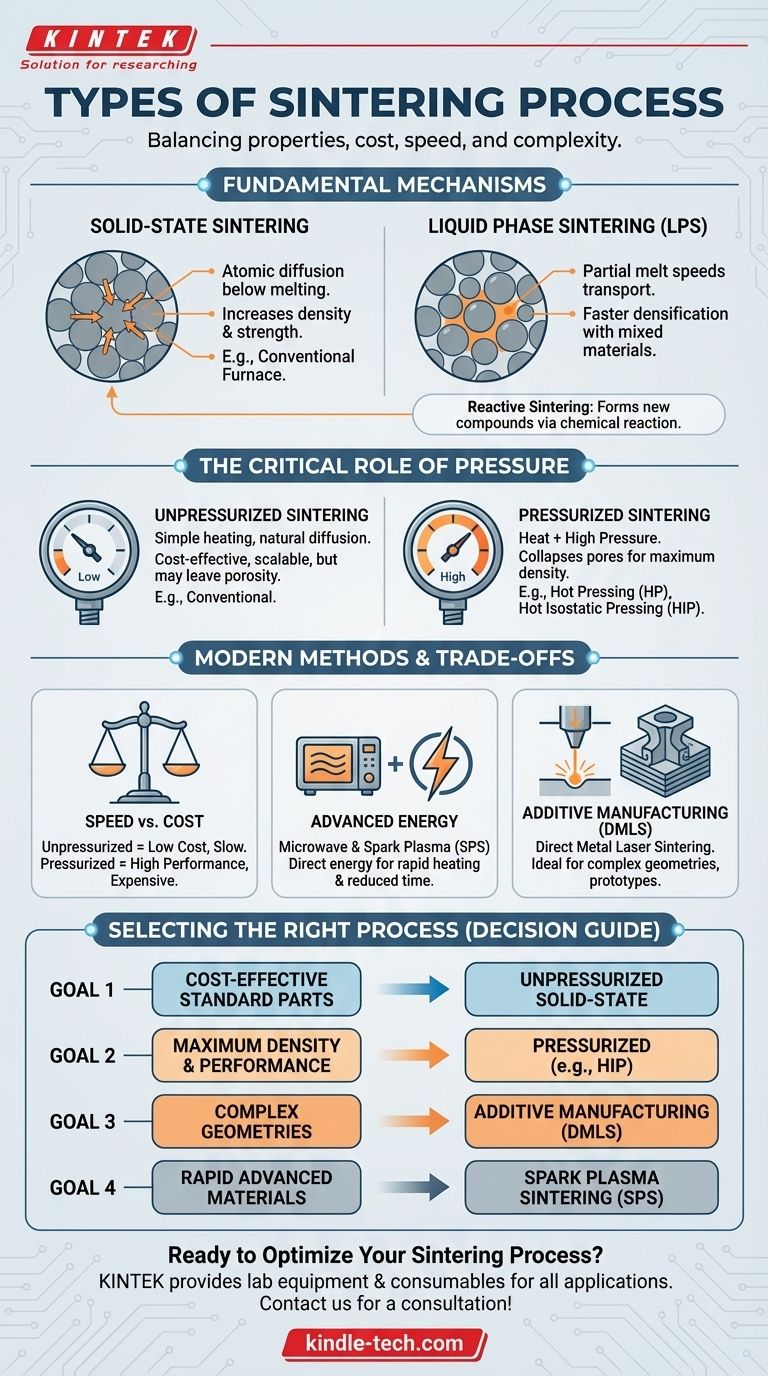

At its core, sintering is a family of processes, not a single method. The primary types can be classified by their fundamental physical mechanism: Solid-State Sintering, where particles bond through atomic diffusion below their melting point, and Liquid Phase Sintering, which uses a partial melt to accelerate densification. Other key classifications distinguish processes by the application of external pressure and the energy source used.

The essential choice in any sintering process is a trade-off. You are balancing the desired final properties of the material—like density and strength—against the cost, speed, and complexity of the manufacturing technique.

The Fundamental Mechanisms of Sintering

To truly understand the different types of sintering, you must first grasp the core mechanisms that drive particles to bond together. The primary distinction is whether the material remains entirely solid or if a liquid is introduced.

Solid-State Sintering: The Classic Approach

This is the most fundamental form of sintering. A compacted powder is heated to a high temperature, typically below the material's melting point.

At this temperature, atoms migrate across the boundaries of the particles, causing them to fuse together. This process, driven by solid-state diffusion, gradually reduces the empty space (porosity) between particles, increasing the material's density and strength.

Conventional sintering, where a part is simply heated in a furnace without external force, is a common example of this method.

Liquid Phase Sintering (LPS): Accelerating the Process

In LPS, the powder compact is composed of at least two different materials, or is heated to a temperature where one component begins to melt.

This small amount of liquid phase wets the solid particles and acts as a high-speed transport path. The solid particles can dissolve, rearrange, and re-precipitate more easily, leading to much faster and more complete densification compared to solid-state sintering.

Reactive Sintering: Creating New Materials

This specialized process involves a chemical reaction between the powder particles during heating.

Instead of simply bonding existing materials, reactive sintering forms an entirely new compound. This is often used to create high-performance ceramics and intermetallic compounds that are difficult to produce by other means.

The Critical Role of Pressure

The second major way to categorize sintering processes is by the use of external pressure. Applying pressure during heating fundamentally changes the densification dynamics.

Unpressurized Sintering: Simplicity and Scale

This is the most common and straightforward category, encompassing conventional sintering. The powder compact is simply heated, and densification occurs naturally through atomic diffusion.

While simpler and more scalable for large production runs, unpressurized methods may struggle to eliminate the final traces of porosity, limiting the ultimate density and mechanical properties of the part.

Pressurized Sintering: Achieving Maximum Density

In these advanced methods, high pressure is applied simultaneously with high temperature. This external force actively pushes particles together, collapsing pores and dramatically aiding the diffusion process.

Hot Pressing (HP) and Hot Isostatic Pressing (HIP) are the principal examples. HIP applies uniform, gas-based pressure from all directions, making it exceptionally effective at producing fully dense, high-performance components.

Understanding the Trade-offs and Modern Methods

The choice between these processes is driven by practical considerations. Modern techniques often employ novel energy sources to overcome the limitations of conventional furnace heating.

Speed vs. Cost: The Core Dilemma

Unpressurized, conventional sintering is often the most cost-effective method but is also the slowest. Pressurized methods like HIP produce superior parts but require highly specialized and expensive equipment.

Advanced Energy Sources: Microwave and Spark Plasma

Rather than heating a part from the outside-in with a furnace, these methods deliver energy more directly to the material.

Microwave Sintering uses microwaves for rapid, volumetric heating. Spark Plasma Sintering (SPS) passes a powerful electric current through the powder, generating intense localized heat at particle contact points while also applying pressure. Both can drastically reduce processing times.

Additive Manufacturing: Direct Metal Laser Sintering (DMLS)

DMLS is a form of 3D printing that builds components layer by layer. A high-power laser selectively melts and fuses thin layers of metal powder.

While technically a melting and solidification process, it is often discussed alongside sintering because it starts with a powder bed and produces dense metal parts. It excels at creating highly complex geometries that are impossible to manufacture with other methods.

Selecting the Right Sintering Process

Your final choice depends entirely on your project's specific goals for performance, complexity, and cost.

- If your primary focus is cost-effective production of standard parts: Conventional, unpressurized solid-state sintering is the established and economical choice.

- If your primary focus is maximum density and mechanical performance: A pressurized method like Hot Isostatic Pressing (HIP) is necessary to achieve near-perfect material integrity.

- If your primary focus is manufacturing parts with complex geometries: Direct Metal Laser Sintering (DMLS) or other additive manufacturing techniques are the ideal solution.

- If your primary focus is rapid processing of advanced ceramics or composites: Exploring advanced methods like Spark Plasma Sintering (SPS) can provide significant time and energy savings.

Understanding these distinct categories transforms sintering from a single step into a powerful toolkit for precise material engineering.

Summary Table:

| Process Type | Key Mechanism | Primary Advantage | Ideal For |

|---|---|---|---|

| Solid-State Sintering | Atomic diffusion below melting point | Cost-effective, simple | Standard parts, large production runs |

| Liquid Phase Sintering (LPS) | Uses a partial melt for faster transport | Accelerated densification | Faster processing with specific material mixes |

| Pressurized Sintering (e.g., HIP) | Applies heat and high pressure simultaneously | Maximum density and performance | High-integrity components, advanced ceramics |

| Spark Plasma Sintering (SPS) | Electric current and pressure for rapid heating | Extremely fast processing times | Advanced ceramics, composites research |

| Direct Metal Laser Sintering (DMLS) | Laser melts powder layers for 3D printing | Complex geometries, design freedom | Prototypes, intricate components |

Ready to Select the Perfect Sintering Process for Your Project?

Choosing the right sintering technique is critical to achieving the desired density, strength, and complexity in your final product. The experts at KINTEK are here to help you navigate these options.

We specialize in providing the lab equipment and consumables needed for a wide range of sintering applications, from conventional furnaces to advanced systems. Our team can help you identify the most efficient and cost-effective solution for your specific material and performance goals.

Let's optimize your manufacturing process together. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- Which is used for elemental analysis? XRF for Fast, Non-Destructive Material Testing

- What are the disadvantages of KBr FTIR? Key Limitations That Impact Your Data Quality

- What is extruded graphite used for? Cost-Effective Conductivity for Industrial Processes

- What temperature does THC get damaged? The Precise Guide to Preserving Potency

- Why is biomass energy not efficient? The Hidden Costs of Low-Energy Fuel

- What are the benefits of bio-oil pyrolysis? Turn Waste into Renewable Energy

- What is the physical sputtering method? A Guide to High-Performance Thin Film Deposition

- Why KBr is used to make the pellet? Achieve High-Quality FTIR Analysis of Solid Samples