At its core, a hydraulic press is a force multiplier. While you may not own one, you interact with its products daily, from the car you drive and the furniture in your home to the cocoa powder in your pantry. It is an essential, yet often invisible, tool used for forging, molding, crushing, and compressing an incredible range of materials.

The true significance of the hydraulic press isn't just its list of uses, but its fundamental ability to convert a small amount of effort into an immense, controllable force. This single principle makes it one of the most versatile and indispensable machines in modern manufacturing.

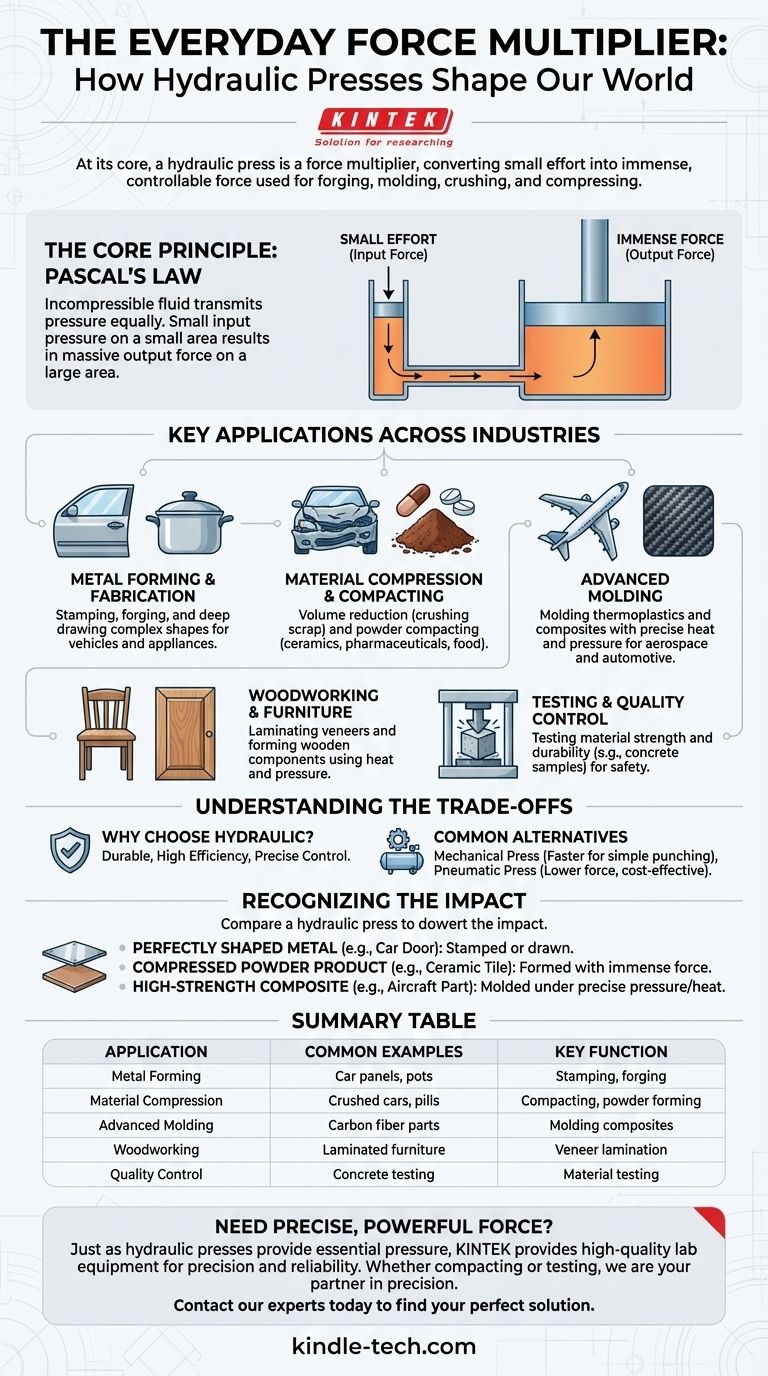

The Core Principle: Pascal's Law in Action

To understand why the hydraulic press is so widely used, we must first understand how it works. It operates on a simple yet powerful principle of fluid dynamics.

How It Multiplies Force

A hydraulic system uses an incompressible fluid, typically oil, to transmit force. When pressure is applied to the fluid in a small cylinder, that same pressure is exerted on a much larger cylinder, resulting in a massive multiplication of the original force.

Why This Matters for Manufacturing

This ability to generate immense and highly controllable pressure is the key to its versatility. It allows manufacturers to shape, bend, and compress incredibly strong materials like steel with precision and relative ease.

Key Applications Across Industries

The principle of force multiplication finds its purpose in an astonishing number of industrial processes. Nearly every major industry relies on this technology.

Metal Forming and Fabrication

This is perhaps the most common application. Hydraulic presses are used for forging, stamping, punching, and deep drawing metal sheets into complex shapes.

The body panels, frame components, and exhaust parts of your car were almost certainly formed by a massive hydraulic press.

Material Compression and Compacting

The immense force generated is perfect for reducing the volume of materials. This is used for crushing cars and other scrap metal into dense, transportable bales.

It's also used for powder compacting, a process that creates solid forms from powders. This technique is used to make everything from fat-free cocoa powder and ceramics to pharmaceutical pills.

Advanced Molding

Modern manufacturing relies on composite materials. Hydraulic presses are critical for molding thermoplastics, carbon fiber, and other composites used in the aerospace, automotive, and military industries.

Woodworking and Furniture Production

Hydraulic hot presses are essential in the furniture industry. They use a combination of heat and pressure to laminate wood veneers onto boards, produce wooden doors, and form furniture plates.

Testing and Quality Control

In laboratory settings, hydraulic presses are used to test the strength and durability of materials. A common example is testing concrete samples to ensure they meet the compressive strength required for construction projects.

Understanding the Trade-offs

While incredibly versatile, the hydraulic press is not the only tool available. Understanding why it's chosen reveals its core strengths.

Why Choose a Hydraulic Press?

Hydraulic presses are known for their durability, high efficiency, and relatively low maintenance. Most importantly, they provide complete control over the pressure throughout the entire stroke, which is critical for complex forming and molding operations.

Common Alternatives

For high-speed, repetitive tasks like simple punching, a mechanical press is often faster. For applications requiring less force, a pneumatic press can be a more cost-effective solution. The choice depends entirely on the specific manufacturing need.

Recognizing the Hydraulic Press's Impact

The applications of the hydraulic press are woven into the fabric of our modern world. Understanding its role helps you see the engineering behind everyday objects.

- If you see a perfectly shaped metal product (like a cooking pot or car door): A hydraulic press almost certainly stamped or drew it into its final form.

- If you use a product made from compressed powder (like a ceramic tile): A hydraulic press provided the immense force needed to create it.

- If you rely on a high-strength composite material (like in an aircraft): A hydraulic press was likely used to mold it under precise pressure and heat.

Ultimately, the hydraulic press stands as a testament to how a fundamental principle of physics can be harnessed to shape the world around us.

Summary Table:

| Application | Common Examples | Key Function |

|---|---|---|

| Metal Forming | Car body panels, cooking pots | Stamping, forging, deep drawing |

| Material Compression | Crushed cars, cocoa powder, pills | Compacting, crushing, powder forming |

| Advanced Molding | Carbon fiber parts, aerospace components | Molding composites with heat and pressure |

| Woodworking | Laminated furniture, wooden doors | Veneer lamination and forming |

| Quality Control | Concrete strength testing | Material testing and analysis |

Need precise, powerful force for your manufacturing or lab processes?

Just as hydraulic presses provide the controlled, immense pressure essential for shaping modern materials, KINTEK provides the high-quality lab equipment essential for precision and reliability. Whether you are compacting powders, testing material strength, or developing new composite materials, the right equipment is the foundation of your success.

Let KINTEK be your partner in precision. We specialize in supplying durable and efficient laboratory equipment and consumables tailored to your specific needs. Contact our experts today to find the perfect press or equipment solution to enhance your production quality and efficiency.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What are the risks of a hydraulic press? Essential Safety and Operational Insights

- What are the methods of infrared spectroscopy? A Guide to Solid, Liquid, and Gas Sample Prep

- Why is precise pressure control critical for Ti-Al-Y alloy powder molding? Ensure Successful Solid-Phase Diffusion

- How does a laboratory high-pressure hydraulic press influence B4C ceramic preforms? Optimize Your Ceramic Skeleton

- How does a hydraulic press system work? Unlock the Power of Force Multiplication

- How does the axial pressure provided by a laboratory hydraulic system influence weld formation? Master Precision Bonding

- How does a uniaxial hydraulic press contribute to the formation of LCO and LATP composite green bodies? Expert Insights

- In which stage of all-solid-state sodium-sulfur battery assembly is a laboratory hydraulic press used? Expert Guide