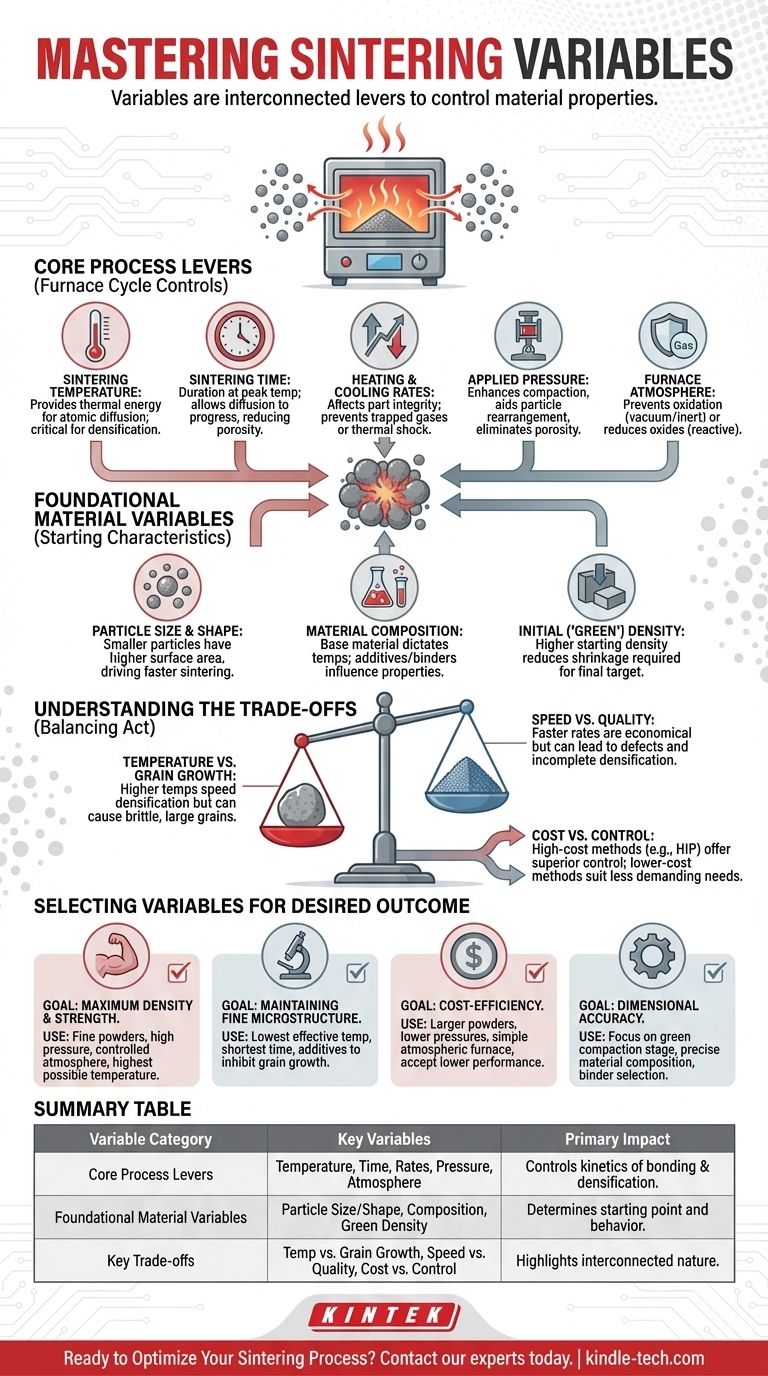

The primary variables in the sintering process are the material's initial characteristics and the conditions applied during heating. Key factors include sintering temperature, time, pressure, and furnace atmosphere, along with the foundational properties of the powder itself, such as particle size and composition. These variables are not independent; they are interconnected levers used to control the final properties of the material.

The core principle of sintering is not just heating a material, but precisely controlling a set of interacting variables. Your goal is to manage atomic diffusion and particle rearrangement to achieve a target density, strength, and microstructure in the final component.

The Core Process Levers

These are the variables you actively control during the furnace cycle. They directly influence the kinetics of how the powder particles bond and densify.

Sintering Temperature

Temperature is the most critical variable driving the sintering process. It provides the thermal energy needed for atoms to diffuse across particle boundaries, causing them to fuse together.

The temperature must be high enough to enable diffusion but remain below the material's melting point. Control is paramount, as even a small deviation of ±3-5 °C can significantly alter the final properties.

Sintering Time

This refers to the duration the material is held at the peak sintering temperature. Time works in conjunction with temperature; a lower temperature may require a longer time to achieve the same level of densification.

Sufficient time allows the diffusion process to progress, reducing porosity and increasing the strength of the component.

Heating and Cooling Rates

The rate at which the material is heated and cooled affects the final part's integrity. A rapid heating rate can trap gases from binders or the atmosphere, creating internal defects.

Similarly, a controlled cooling rate is essential to prevent thermal shock, cracking, and to achieve the desired final crystalline structure, such as martensite in some steels.

Applied Pressure

While some sintering occurs at atmospheric pressure, applying external pressure significantly enhances the process.

Pressure aids in the initial compaction (creating the "green" part), helps particles rearrange more efficiently, and actively works to squeeze out and eliminate remaining porosity, leading to higher density.

Furnace Atmosphere

The atmosphere inside the furnace prevents unwanted chemical reactions, primarily oxidation. Sintering is often performed in a vacuum or an inert atmosphere like argon or nitrogen.

In some cases, a reactive atmosphere is used intentionally to reduce surface oxides that may have formed on the initial powder particles, cleaning them to ensure a strong metallic bond.

The Foundational Material Variables

The success of the sintering process is determined long before the material enters the furnace. The characteristics of the starting powder are a critical set of variables.

Particle Size and Shape

Smaller particles have a higher surface-area-to-volume ratio, which provides a stronger driving force for sintering. This means they typically sinter faster and at lower temperatures.

The shape and distribution of particle sizes also influence how well the powder can be packed, which determines the starting density of the component before heating.

Material Composition

The base material dictates the fundamental temperature and time requirements. Furthermore, additives play a crucial role.

Binding agents are often mixed in to help the compacted ("green") part hold its shape, while alloying elements like copper or carbides can be added to the powder to achieve specific final properties like hardness or conductivity.

Initial ("Green") Density

This is the density of the part after it has been compacted in a mold but before it is heated. A higher green density means the particles are already closer together.

This provides a better starting point for the furnace cycle, requiring less shrinkage to achieve the final target density and reducing the likelihood of defects.

Understanding the Trade-offs

Controlling sintering variables is a balancing act. Optimizing for one property often comes at the expense of another.

Temperature vs. Grain Growth

Higher temperatures increase the rate of densification, which is generally desirable. However, excessive temperature or time can cause grain growth, where smaller crystals merge into larger ones.

Large grains can sometimes make a material more brittle, so there is a constant trade-off between achieving maximum density and maintaining a fine, strong microstructure.

Speed vs. Quality

Faster heating rates and shorter cycle times are more economical for production. However, rushing the process can be detrimental.

Rapid heating can fail to properly burn out binders, and insufficient time at temperature can lead to incomplete densification. This creates a trade-off between manufacturing throughput and final part quality.

Cost vs. Control

The most advanced sintering processes, like Hot Isostatic Pressing (HIP), use high pressure and temperature in a tightly controlled atmosphere. This produces superior parts but comes at a significant cost.

Simpler atmospheric sintering is far less expensive but offers less control over porosity and final density, making it suitable for less demanding applications.

Selecting Variables for Your Desired Outcome

The optimal set of variables depends entirely on the goal for the final component. Use these principles as a guide.

- If your primary focus is maximum density and strength: Utilize fine powders, high applied pressure, a controlled (vacuum or inert) atmosphere, and the highest temperature possible without causing excessive grain growth.

- If your primary focus is maintaining a fine-grained microstructure: Use the lowest effective temperature and shortest time required to meet your density target, and consider using additives that inhibit grain growth.

- If your primary focus is cost-efficiency for non-critical parts: You can likely use larger powders, lower compaction pressures, and a simpler atmospheric furnace, accepting slightly lower final performance.

- If your primary focus is dimensional accuracy for complex shapes: Pay close attention to the initial material composition, binder selection, and the "green" compaction stage to ensure the part is perfect before it ever enters the furnace.

Mastering these variables transforms sintering from a simple heating process into a precise engineering tool for creating high-performance materials.

Summary Table:

| Variable Category | Key Variables | Primary Impact on Process |

|---|---|---|

| Core Process Levers | Temperature, Time, Heating/Cooling Rates, Pressure, Furnace Atmosphere | Controls the kinetics of particle bonding and densification during the furnace cycle. |

| Foundational Material Variables | Particle Size/Shape, Material Composition, Initial Green Density | Determines the starting point and fundamental behavior of the material during sintering. |

| Key Trade-offs | Temperature vs. Grain Growth, Speed vs. Quality, Cost vs. Control | Highlights the interconnected nature and balancing act required when setting variables. |

Ready to Optimize Your Sintering Process?

Mastering the delicate balance of sintering variables is key to producing high-performance components. KINTEK specializes in providing the advanced lab equipment and consumables you need for precise control over temperature, atmosphere, and pressure.

Whether you are developing new materials or optimizing production for maximum density, strength, or cost-efficiency, our solutions are designed to meet your specific laboratory needs.

Contact our experts today to discuss how we can help you achieve perfect sintering results.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- Does quartz have a high melting point? Discover Its Superior High-Temperature Performance

- What is the role of a constant temperature shaking incubator in the immobilization of cadmium ions by SRB?

- What are different techniques to synthesize nanomaterials? Top-Down vs. Bottom-Up Methods Explained

- How does a high-precision electric balance function within a TGA system? Master Precise Re-oxidation Kinetics

- What happens during sintering of ceramics? A Guide to Transforming Powder into Dense, Strong Parts

- How to select the best rotary vane pump for specific needs? Match Your Application's Requirements

- What transformation occurs during LAGP 800°C-900°C heat treatment? Mastering NASICON Crystallization and Densification

- Why is a high-sealing reaction system required for corrosion evaluation? Stop the Oxidation-Chlorination Cycle