At its core, Physical Vapor Deposition (PVD) has three primary variants. These distinct families of processes are Thermal Evaporation, Sputtering, and Arc Evaporation (often called Cathodic Arc Deposition). While all PVD methods occur in a vacuum to deposit a thin film onto a surface, they are fundamentally differentiated by the physical mechanism used to turn the solid source material into a vapor.

The critical distinction between PVD variants is not the final coating, but the energy source used to liberate atoms from the source material. This initial step—whether it's boiling, ballistic impact, or a high-current arc—directly dictates the energy of the deposited atoms and, consequently, the final properties of the film, such as its density, adhesion, and hardness.

The Shared Goal: Moving Atoms in a Vacuum

Before examining the differences, it's crucial to understand the process all PVD variants have in common. The goal is always to transport material from a solid source (called a "target" or "precursor") onto a component (the "substrate") in a high-vacuum environment.

This process prevents the vaporized coating material from reacting with air and ensures a clean, direct path to the substrate. The choice of variant simply determines how the journey from solid to vapor begins.

The Primary PVD Methods Explained

The variants are best understood by the energy they apply to the source material. Each method imparts a different level of energy to the atoms, which has significant consequences for the resulting film.

Thermal Evaporation: Using Heat

This is conceptually the simplest method. The source material is heated in the vacuum chamber until it boils or sublimates, releasing a vapor of atoms that then travels and condenses onto the cooler substrate.

There are two common ways to achieve this heating:

- Resistive Heating: An electric current is passed through a boat or filament holding the source material, heating it like a toaster element.

- Electron-Beam (E-Beam) Evaporation: A high-energy beam of electrons is fired at the source material, causing intense, localized heating and evaporation.

Sputtering: Using Kinetic Impact

Sputtering operates like a microscopic game of billiards. High-energy ions (typically from an inert gas like Argon) are accelerated to strike the solid source target. This collision has enough force to physically knock out, or "sputter," atoms from the target surface.

Key sub-types include:

- Magnetron Sputtering: This is the most common industrial sputtering method. Magnets are placed behind the target to trap electrons near its surface, which dramatically increases the efficiency of ion creation and results in a much higher deposition rate.

- Ion Beam Sputtering: A separate ion source generates a controlled beam of ions that is directed at the target, offering very precise control over the process.

- Reactive Sputtering: A reactive gas (like nitrogen or oxygen) is introduced into the chamber. The sputtered metal atoms react with this gas on their way to the substrate to form a compound film, such as Titanium Nitride (TiN) or Aluminum Oxide (Al₂O₃).

Arc Evaporation: Using an Electric Arc

Also known as Cathodic Arc Deposition, this is a very high-energy process. A high-current, low-voltage electric arc is struck on the surface of the solid source material (the cathode).

The arc creates a tiny, intensely hot, and mobile spot that locally vaporizes the material, ejecting a highly ionized vapor. This high level of ionization gives the atoms significant energy as they are accelerated toward the substrate, resulting in extremely dense and well-adhered coatings.

Understanding the Trade-offs

No single PVD variant is universally superior; the optimal choice is dictated by the desired outcome. The primary trade-off is between process energy, control, and complexity.

Film Density and Adhesion

Higher-energy processes produce more robust films. The highly ionized vapor from Arc Evaporation results in exceptionally dense and strongly bonded coatings, ideal for cutting tools. Sputtering also produces dense, high-adhesion films. Thermal Evaporation, being a lower-energy process, typically results in less dense films with lower adhesion.

Process Control and Complexity

Sputtering offers excellent control over film composition, making it ideal for depositing complex alloys where the original material composition must be precisely maintained. Specialized variants like Molecular Beam Epitaxy (MBE)—a highly refined form of thermal evaporation—provide the ultimate, atomic-layer precision required for manufacturing semiconductors.

Material Compatibility

The choice of method can depend on the material. Refractory metals with very high melting points can be difficult to evaporate thermally but are easily deposited using sputtering. Conversely, some materials may be damaged or decompose under high-energy sputtering or arc processes.

Making the Right Choice for Your Goal

Selecting the correct PVD variant requires matching the process capabilities to the application's demands.

- If your primary focus is wear resistance and hardness for tools: Arc Evaporation is the leading choice due to its high-energy process that creates extremely dense and adherent hard coatings.

- If your primary focus is precision functional or decorative coatings: Magnetron Sputtering offers a superb balance of control, adhesion, and material versatility for a wide range of applications.

- If your primary focus is cost-effective optical or simple metal coatings: Thermal Evaporation is often sufficient and more economical for applications like aluminizing mirrors or coating plastics where extreme hardness isn't required.

- If your primary focus is cutting-edge electronics and semiconductor research: Molecular Beam Epitaxy (MBE) provides the unparalleled, layer-by-layer control necessary for building complex crystal structures.

Understanding these foundational differences in how atoms are vaporized is the key to selecting the PVD process that will deliver the precise performance your application requires.

Summary Table:

| PVD Variant | Energy Source | Key Characteristics | Best For |

|---|---|---|---|

| Thermal Evaporation | Heat (Resistive/E-Beam) | Lower energy, less dense films, cost-effective | Optical coatings, simple metal layers |

| Sputtering | Kinetic impact (Ion bombardment) | Excellent control, dense films, versatile | Precision functional/decorative coatings, alloys |

| Arc Evaporation | Electric arc | High energy, extremely dense/hard films | Wear-resistant coatings for cutting tools |

Selecting the optimal PVD process is critical for your application's success. The right variant determines your coating's adhesion, density, and performance. KINTEK specializes in providing advanced lab equipment and consumables for all PVD processes, helping laboratories achieve precise and reliable results. Let our experts guide you to the perfect solution for your specific needs—contact us today to discuss your project!

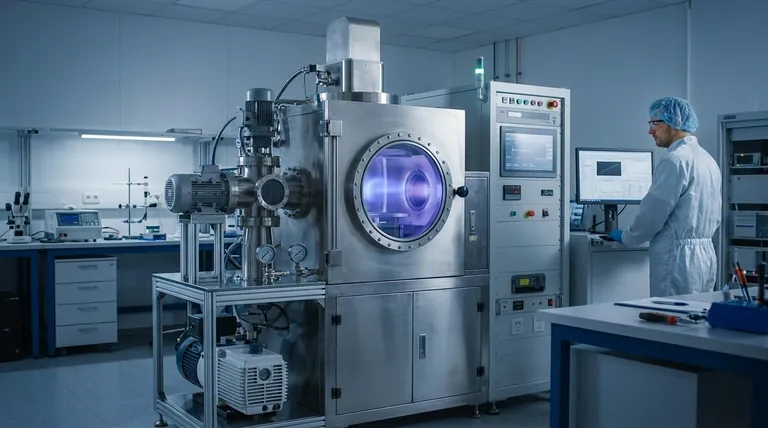

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells