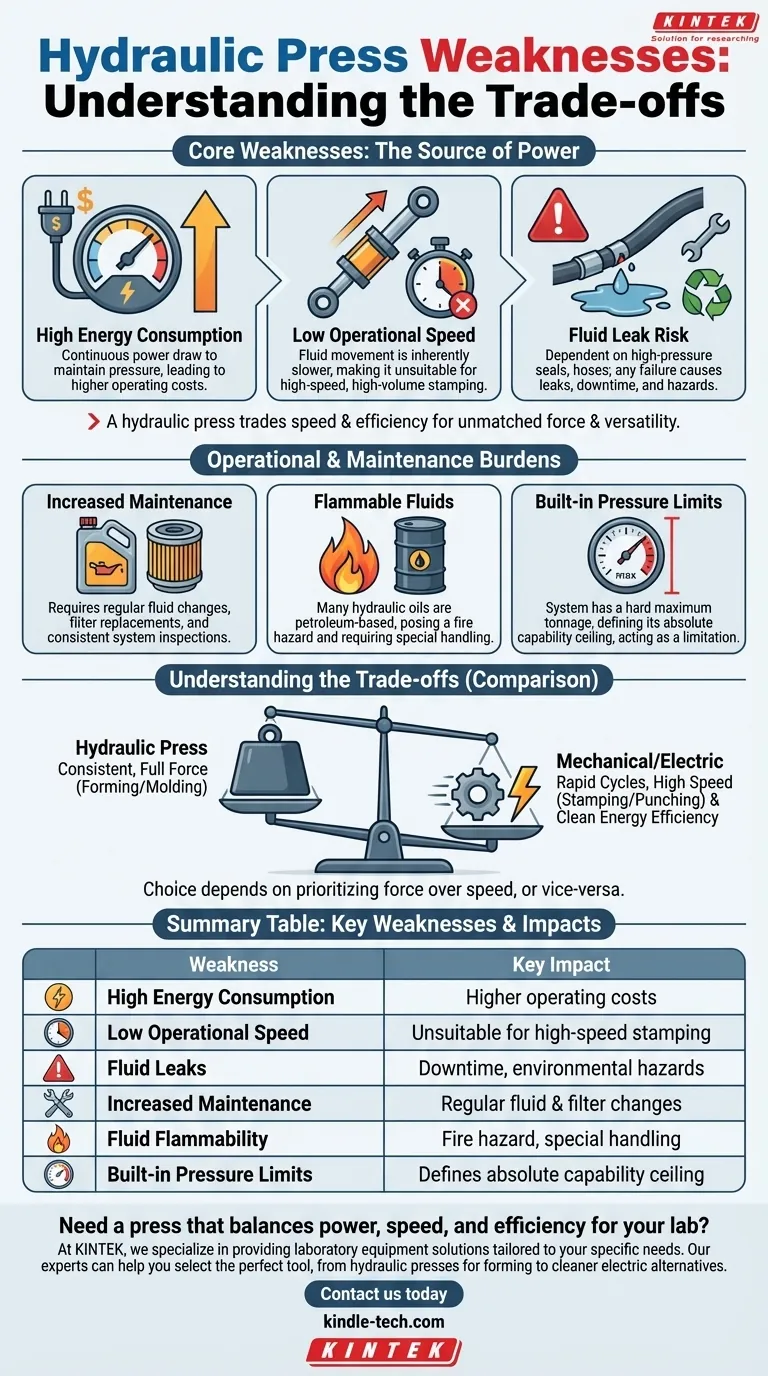

At its core, a hydraulic press's primary weaknesses stem from the very fluid that gives it power. The main disadvantages include high energy consumption, relatively low operational speed, and the ongoing risk of fluid leaks, which necessitates more diligent maintenance compared to purely mechanical systems.

While unmatched in generating immense and controllable force, a hydraulic press trades raw speed and energy efficiency for its power and versatility. Understanding this central trade-off is critical for determining if it's the right solution for your needs.

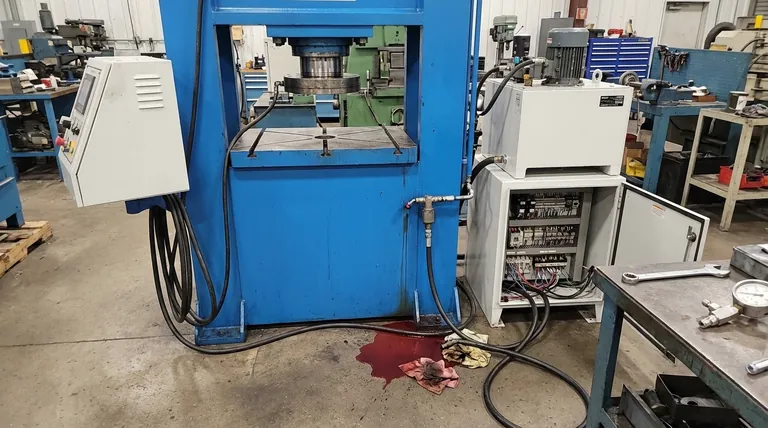

The Source of Power and Its Inherent Downsides

A hydraulic press operates on Pascal's Law: pressure applied to a confined fluid is transmitted equally in all directions. This principle allows a small force on a small piston to generate a massive force on a larger piston, but this mechanism introduces specific operational challenges.

High Energy Consumption

A hydraulic pump must run to maintain pressure, even when the press is idle or holding a position. This continuous power draw can lead to significantly higher energy consumption, especially compared to mechanical presses that only draw maximum power during the actual stroke.

Low Operational Speed

Moving fluid takes time. The process of pumping hydraulic fluid into the cylinder to build pressure and perform a stroke is inherently slower than the crank-and-flywheel action of a mechanical press. This makes hydraulic presses less suitable for high-speed, high-volume operations like rapid stamping.

The Constant Risk of Fluid Leakage

The entire system is dependent on a network of high-pressure seals, hoses, and fittings. Any failure in these components results in a fluid leak. Leaks are not just a maintenance issue; they represent an operational failure, an environmental hazard, and a potential safety risk.

Operational and Maintenance Burdens

While a hydraulic press has fewer moving parts than some complex mechanical counterparts, its reliance on a fluid power system introduces unique maintenance demands.

Increased Maintenance Requirements

The hydraulic system itself is a point of failure. The hydraulic fluid must be kept clean, filtered, and periodically replaced. Seals, pumps, valves, and hoses wear out and require consistent inspection and service to prevent costly downtime.

Flammable or Hazardous Fluids

Many hydraulic oils are petroleum-based and flammable, creating a fire hazard in certain environments. While fire-resistant fluids exist, they are often more expensive and may have different performance characteristics.

Built-in Pressure Limits

While often cited as a safety feature (overload protection), the maximum pressure rating is also a hard limitation. The system is designed to operate up to a specific tonnage and cannot exceed it, which defines the absolute ceiling of its capability.

Understanding the Trade-offs: Hydraulic vs. Other Presses

Choosing a press is about aligning the machine's characteristics with your production goals. The weaknesses of a hydraulic press are most apparent when compared to mechanical or electric alternatives.

Speed vs. Force Control

A mechanical press is built for speed, offering rapid cycles ideal for blanking and punching. However, its force varies throughout the stroke. A hydraulic press is slower but delivers consistent, full force at any point in its stroke, making it superior for deep drawing, forming, and molding.

System Complexity vs. Mechanical Simplicity

A simple mechanical press has a straightforward drive train. A hydraulic press adds the complexity of a fluid power system, including a motor, pump, reservoir, fluid, filters, valves, and high-pressure plumbing. Each component is a potential point of failure that requires specialized knowledge to diagnose and repair.

Cost: Initial vs. Operational

For high-tonnage applications, a hydraulic press often has a lower initial purchase cost than a mechanical press of equivalent capacity. However, its higher energy consumption and the ongoing costs of fluid, filters, and system maintenance can lead to a higher total cost of ownership over its lifespan.

Making the Right Choice for Your Application

The "best" type of press is entirely dependent on your specific task. A weakness in one context is a necessary trade-off in another.

- If your primary focus is controllable force for forming or molding: A hydraulic press is the ideal choice, as its weaknesses in speed are outweighed by its superior force control and tonnage capacity.

- If your primary focus is high-speed stamping or punching: A mechanical press is almost always a better fit, as its rapid cycle times are critical for high-volume production.

- If your primary focus is cleanliness and energy efficiency: A modern electric or servo-mechanical press may be the superior option, as it eliminates fluid-related issues and offers precise control with lower energy use.

Understanding these inherent limitations is the first step toward leveraging a hydraulic press's unmatched power effectively.

Summary Table:

| Weakness | Key Impact |

|---|---|

| High Energy Consumption | Continuous power draw, even when idle, leads to higher operating costs. |

| Low Operational Speed | Fluid movement is slower than mechanical actions, unsuitable for high-speed stamping. |

| Risk of Fluid Leaks | Leaks cause downtime, environmental hazards, and require diligent seal maintenance. |

| Increased Maintenance | Requires regular fluid changes, filter replacements, and system inspections. |

| Fluid Flammability | Petroleum-based oils pose a fire hazard, requiring special handling or expensive alternatives. |

| Built-in Pressure Limits | System has a hard maximum tonnage, defining its absolute capability ceiling. |

Need a press that balances power, speed, and efficiency for your lab?

At KINTEK, we specialize in providing laboratory equipment solutions tailored to your specific needs. Whether you require the immense force of a hydraulic press for forming and molding or are exploring cleaner, more efficient alternatives like electric or servo-mechanical presses, our experts can help you select the perfect tool for your application.

Contact us today using the form below to discuss your requirements and discover how KINTEK can enhance your lab's productivity and safety.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual Lab Heat Press

People Also Ask

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.