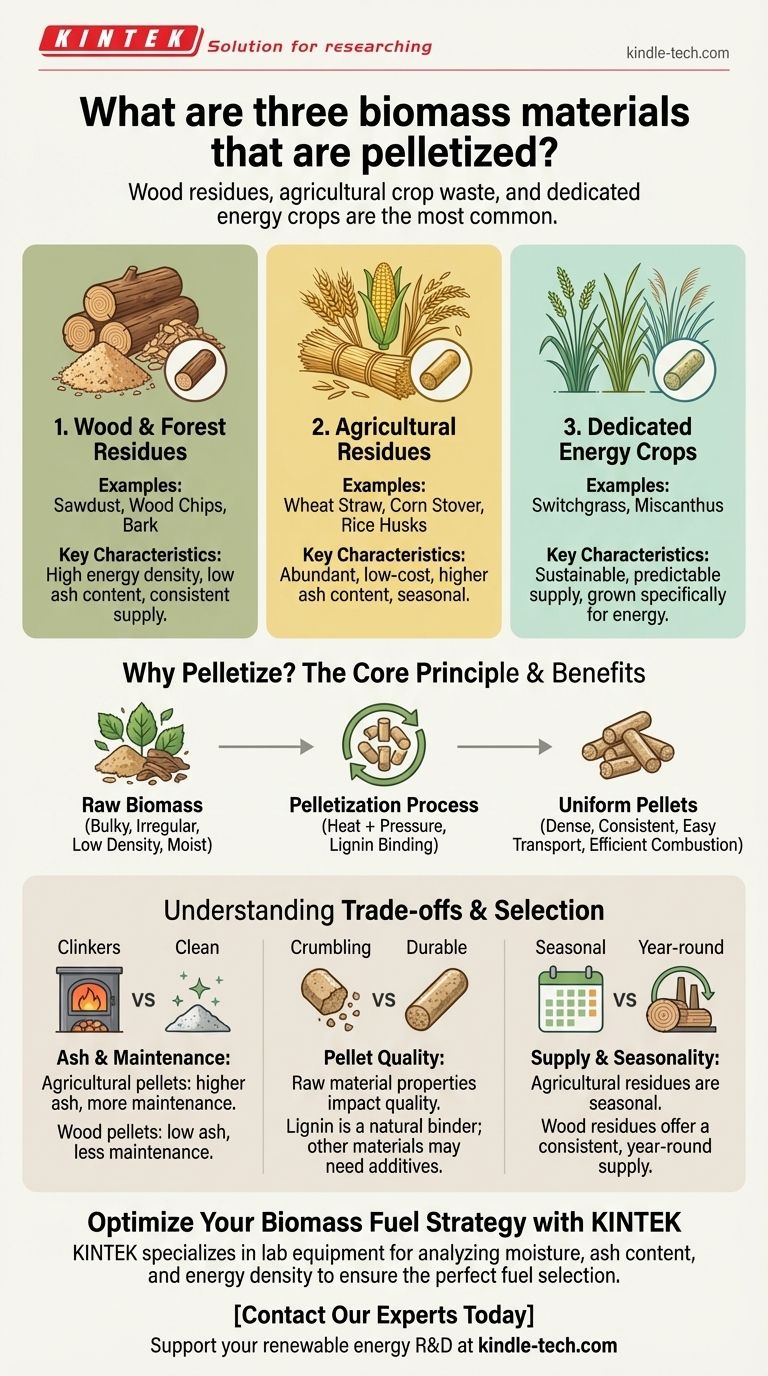

In short, three of the most common biomass materials that are pelletized are wood residues, agricultural crop waste, and dedicated energy crops. These materials are chosen for their abundance and energy content, with wood pellets from sources like sawdust and wood chips being the most established in the market.

The core purpose of pelletizing biomass is not just about using waste; it's about transforming low-density, irregular raw materials into a uniform, energy-dense fuel that is easy to store, transport, and use in automated systems.

Why Pelletize Biomass? The Core Principle

The process of creating pellets solves the fundamental logistical problems associated with raw biomass. It's a critical step in making biomass a viable, large-scale energy source.

The Problem with Raw Biomass

Raw biomass, such as loose sawdust or straw, has a very low energy density. It is bulky, often has high and inconsistent moisture content, and its irregular shape makes it difficult to handle.

These factors make it inefficient and expensive to transport and nearly impossible to use in automated boiler or furnace feeding systems.

From Loose Waste to Dense Fuel

Pelletization uses immense pressure and heat to compress the raw material. This process drives out moisture and forces the material into a small, dense, and uniform shape.

The natural lignin within plant matter often acts as a binder, holding the pellet together without the need for artificial glues.

The Benefits of a Uniform Fuel

The resulting pellets have a much higher energy density and consistent properties. This uniformity is crucial for efficient combustion and allows for the use of automated, screw-fed systems common in modern heating applications.

Key Categories of Pelletized Biomass

While many organic materials can be pelletized, they generally fall into three primary categories based on their origin.

Wood and Forest Residues

This is the most common and mature category of biomass pellets. They are typically made from the byproducts of the lumber and furniture industries.

Key examples include sawdust, wood chips, and bark. Wood pellets are prized for their high energy content and relatively low ash content after burning.

Agricultural Residues

This category utilizes the leftover material after a food crop has been harvested. It represents a massive, often underutilized, energy resource.

Common examples include wheat straw, corn stover (stalks and leaves), and rice husks. These materials are abundant and low-cost but can vary in quality.

Dedicated Energy Crops

These are non-food crops grown specifically for the purpose of energy production. They are chosen for their fast growth rate and high yield per acre.

Prominent examples include grasses like switchgrass and miscanthus. They offer a more controlled and predictable supply chain compared to waste-based sources.

Understanding the Trade-offs

The choice of biomass material is not just about availability; it has direct consequences for equipment performance and maintenance.

Ash Content and Maintenance

A critical difference between biomass types is their ash content. Agricultural residues often contain higher levels of minerals like silica and potassium.

This results in more ash after combustion, which can form hard deposits (clinkers) in a furnace, requiring more frequent cleaning and maintenance compared to low-ash wood pellets.

Material Properties and Pellet Quality

The physical and chemical properties of the raw material directly impact the quality of the final pellet. Wood's high lignin content makes it an excellent natural binder.

Other materials may require conditioning or the addition of binders to produce a durable pellet that doesn't crumble during transport.

Supply Chain and Seasonality

Relying on agricultural residues means dealing with a seasonal supply chain, as materials are only available after the harvest.

In contrast, wood residues from sawmills can provide a more consistent, year-round supply, which is a significant advantage for industrial-scale operations.

Selecting the Right Biomass for Your Application

Your ultimate goal dictates which type of biomass pellet is the most suitable choice.

- If your primary focus is maximum energy output and minimal maintenance: High-quality wood pellets are the industry standard due to their high energy density and low ash content.

- If your primary focus is cost-effectiveness and utilizing local resources: Agricultural pellets can be an excellent, low-cost alternative, provided you are prepared for more frequent equipment maintenance.

- If your primary focus is developing a large-scale, sustainable fuel source: Dedicated energy crops provide a predictable, controllable, and long-term supply chain essential for power generation.

Ultimately, understanding the characteristics of each biomass source allows you to harness its potential as a clean and renewable fuel.

Summary Table:

| Biomass Category | Common Examples | Key Characteristics |

|---|---|---|

| Wood & Forest Residues | Sawdust, Wood Chips, Bark | High energy density, low ash content, consistent supply |

| Agricultural Residues | Straw, Corn Stover, Rice Husks | Abundant, low-cost, but higher ash content and seasonal |

| Dedicated Energy Crops | Switchgrass, Miscanthus | Sustainable, predictable supply, grown specifically for energy |

Ready to optimize your biomass fuel strategy?

Understanding the differences between wood, agricultural, and energy crop pellets is the first step to maximizing efficiency and minimizing costs. The right choice depends entirely on your specific goals, whether it's maximum energy output, cost-effectiveness, or a sustainable, long-term supply.

KINTEK specializes in lab equipment and consumables for analyzing biomass materials. We can provide the tools you need to test moisture content, ash content, and energy density, ensuring you select the perfect pelletized fuel for your laboratory or pilot-scale operations.

Contact our experts today to discuss your biomass testing needs and discover how KINTEK can support your renewable energy research and development.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success