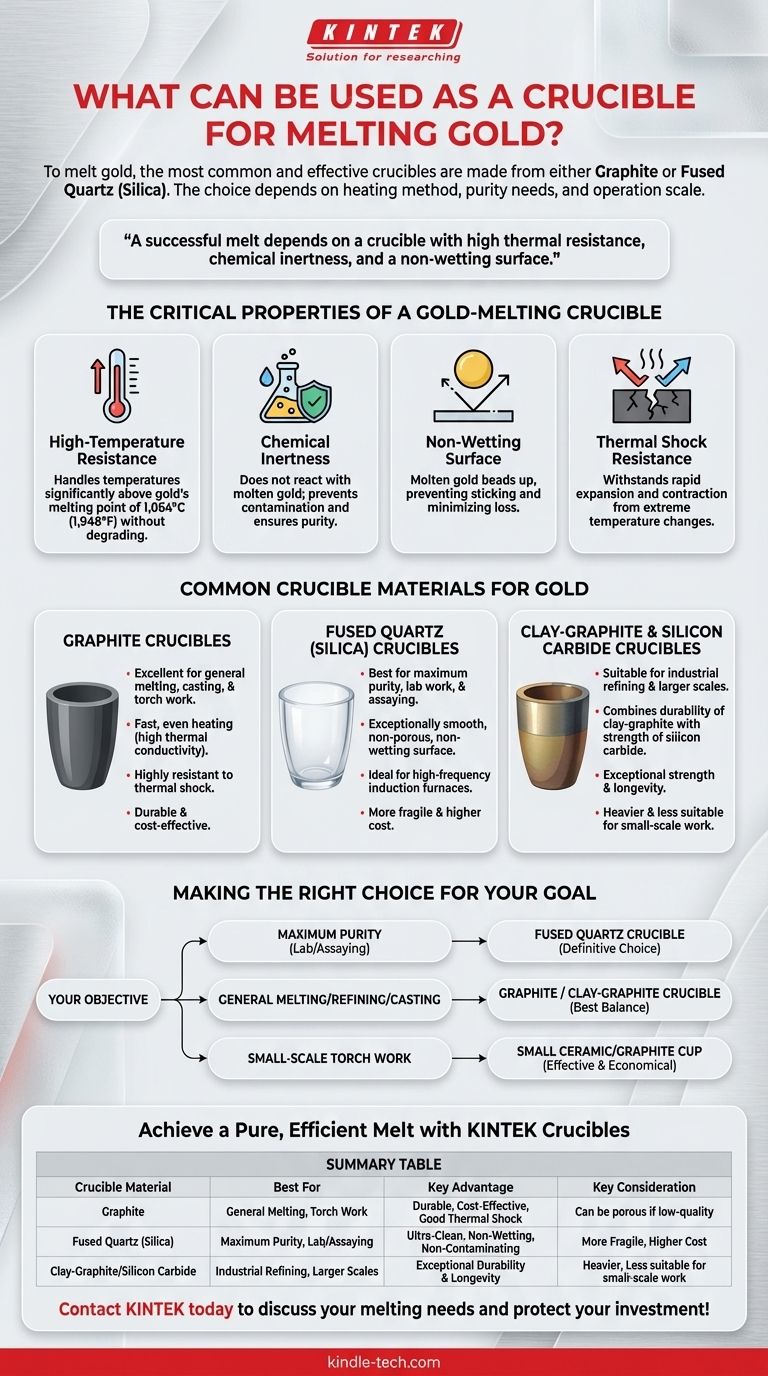

To melt gold, the most common and effective crucibles are made from either graphite or fused quartz (silica). The choice between them depends on your specific heating method, the desired level of purity, and the scale of your operation. Both materials can withstand the high temperatures required while ensuring the gold is not contaminated.

The core challenge isn't just finding a container that won't melt, but one that won't react with, absorb, or contaminate your valuable gold. A successful melt depends on a crucible with high thermal resistance, chemical inertness, and a non-wetting surface to prevent any loss of material.

The Critical Properties of a Gold-Melting Crucible

Understanding why certain materials are used is key to avoiding costly mistakes. Any crucible suitable for gold must possess a specific set of characteristics.

High-Temperature Resistance

Gold melts at 1,064°C (1,948°F). Your crucible must comfortably handle temperatures significantly above this point without degrading, cracking, or melting itself.

Chemical Inertness

The crucible material cannot chemically react with molten gold. Any reaction will introduce impurities into your final product, reducing its purity and value. This is why materials like steel are entirely unsuitable.

Non-Wetting Surface

This is a crucial property for precious metals. A non-wetting surface means the molten gold beads up, much like water on a waxed car. It prevents the metal from sticking to or soaking into the crucible walls, ensuring you can pour it cleanly and minimize loss.

Thermal Shock Resistance

A crucible undergoes extreme temperature changes, from room temperature to over 1000°C and back again. The material must be able to withstand this rapid expansion and contraction without fracturing.

Common Crucible Materials for Gold

While several materials can work, two stand out as the industry standards for their reliability and performance.

Graphite Crucibles

Graphite is an excellent all-around choice. Its high thermal conductivity allows for fast and even heating, and it is highly resistant to thermal shock. It is a durable and relatively cost-effective option for a wide range of melting applications.

Fused Quartz (Silica) Crucibles

For applications demanding the highest purity, fused quartz is superior. It offers an exceptionally smooth, non-porous surface that is highly non-wetting and non-contaminating. These are often used in high-frequency induction furnaces where a clean melt is paramount.

Clay-Graphite & Silicon Carbide Crucibles

These are composite crucibles that combine materials to optimize performance. Clay-graphite blends the properties of both materials for durability, while silicon carbide offers exceptional strength and longevity, making them suitable for larger-scale industrial refining.

Understanding the Trade-offs

No single crucible is perfect for every situation. The right choice involves balancing cost, durability, and the specific requirements of your heating source.

Purity vs. Cost and Durability

Fused quartz offers the highest purity but is more fragile and typically more expensive than graphite. Graphite and clay-graphite crucibles provide excellent durability and are more economical for general-purpose melting and casting.

The Impact of Your Heating Method

The way you heat the crucible matters. Torch melting exposes the crucible to direct, intense flame, making durable graphite or clay-graphite a robust choice. Induction furnaces, however, heat the metal directly, making a non-conductive and ultra-clean quartz crucible an ideal partner.

The Risk of Porosity

Always use a crucible made from a dense material structure, as low-quality or damaged crucibles can be porous. Molten gold can penetrate these pores, resulting in material loss and creating stress that will eventually crack the crucible.

Making the Right Choice for Your Goal

To select the best crucible, match the material to your primary objective.

- If your primary focus is maximum purity for lab work or assaying: A fused quartz crucible is the definitive choice to prevent contamination.

- If your primary focus is general melting, refining, or casting: A high-quality graphite or clay-graphite crucible provides the best balance of performance, durability, and cost.

- If your primary focus is small-scale jewelry work with a torch: A small, cup-style ceramic or graphite crucible is both effective and economical.

Choosing the correct crucible is the foundational step toward a clean, successful, and efficient melt.

Summary Table:

| Crucible Material | Best For | Key Advantage | Key Consideration |

|---|---|---|---|

| Graphite | General Melting, Torch Work | Durable, Cost-Effective, Good Thermal Shock Resistance | Can be porous if low-quality |

| Fused Quartz (Silica) | Maximum Purity, Lab/Assaying | Ultra-Clean, Non-Wetting, Non-Contaminating | More Fragile, Higher Cost |

| Clay-Graphite / Silicon Carbide | Industrial Refining, Larger Scales | Exceptional Durability & Longevity | Heavier, Less suitable for small-scale work |

Achieve a Pure, Efficient Melt with KINTEK Crucibles

Your gold's purity and your process's efficiency depend on the right lab equipment. KINTEK specializes in high-performance crucibles for laboratory and jewelry applications, ensuring your valuable materials are handled with care.

- Maximize Purity: Our fused quartz crucibles are ideal for contamination-sensitive applications like assaying.

- Enhance Durability: Our graphite and clay-graphite crucibles offer the perfect balance of performance and cost-effectiveness for general melting and casting.

Let our experts help you select the perfect crucible for your specific heating method and purity requirements.

Contact KINTEK today to discuss your melting needs and protect your investment!

Visual Guide

Related Products

- High Purity Pure Graphite Crucible for Evaporation

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

People Also Ask

- Why is an alumina (corundum) crucible necessary for thermal annealing? Ensure High-Purity Material Synthesis

- What is the function of a water-cooled copper crucible? Ensure Purity in High-Entropy Alloy Melting

- What can I use as a crucible for melting gold? Choose the Right Material for a Clean, Efficient Melt

- What needs to be checked before using a crucible? A Guide to Safe and Effective High-Temperature Work

- How does the choice between graphite and metal-lined crucibles affect molten salt corrosion? Find the Right Research Tool

- What role do alumina crucibles play in synthesizing lithium salt precursors like Li3BO3? Ensure High-Purity Synthesis

- Why is the use of high-performance alumina crucibles necessary when melting alloys with high nickel content?

- Why is a molybdenum crucible selected for lead-bismuth eutectic corrosion experiments? Ensure Pure Testing Results