In short, sintering fundamentally transforms a loose powder into a solid object. This process dramatically affects a material's physical and performance characteristics, including its density, strength, conductivity, and even its final geometric shape.

The core effect of sintering is the reduction of porosity. By using heat below the melting point to fuse particles together, sintering closes the gaps between them, which in turn enhances nearly every other critical material property.

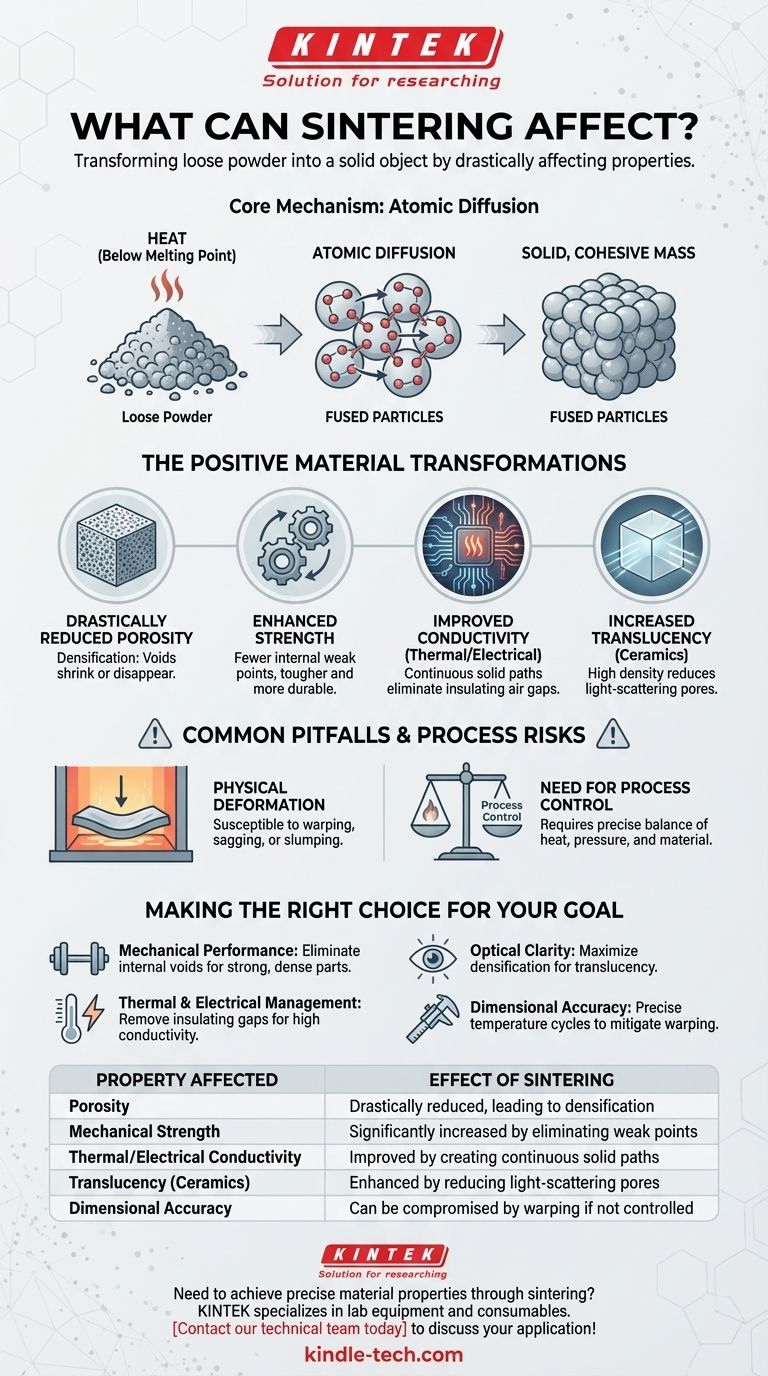

How Sintering Fundamentally Works

Sintering is not a melting process. Instead, it relies on a more subtle mechanism at the atomic level to create strong, dense parts from powders.

The Core Mechanism: Atomic Diffusion

Sintering involves heating a compacted powder to a high temperature, but one that remains below the material's melting point.

This heat energizes the atoms in the individual particles, causing them to migrate and diffuse across the boundaries where particles touch.

This atomic movement effectively fuses the particles together, gradually eliminating the empty spaces (pores) between them and forming a solid, cohesive mass.

From Loose Powder to Integrated Part

The process typically begins by compressing a powder, sometimes with a temporary binder, into a desired shape called a "green part."

When heated, this binder burns away, and the atomic diffusion process takes over. The individual particles bond, and the entire component densifies and strengthens.

The Positive Material Transformations

The primary goal of sintering is to improve a material's properties by consolidating its structure. The reduction in porosity is the catalyst for these enhancements.

Drastically Reduced Porosity

The most direct outcome of sintering is densification. As particles fuse, the voids between them shrink or disappear entirely.

This creates a much more solid and less porous final product compared to the initial compacted powder.

Enhanced Strength and Integrity

A direct consequence of lower porosity is a significant increase in mechanical strength.

Fewer voids mean fewer internal weak points where cracks can initiate and propagate. This results in a part that is tougher and more durable.

Improved Thermal and Electrical Conductivity

Pores, which are typically filled with air, act as insulators. By eliminating these gaps, sintering creates a more continuous, solid path for energy to travel.

This leads to a marked improvement in both thermal and electrical conductivity, a critical factor for many electronic and high-temperature applications.

Increased Translucency

In materials like technical ceramics, pores are the primary cause of opacity because they scatter light.

By creating a highly dense, pore-free structure, sintering can dramatically increase the translucency of a material, allowing more light to pass through it.

Common Pitfalls and Process Risks

While powerful, the sintering process is sensitive and requires precise control. Without it, the final part can be compromised.

The Danger of Physical Deformation

The high temperatures involved make the component susceptible to the forces of gravity and friction within the furnace.

This can lead to undesirable defects in the final part, such as warping, sagging, or slumping, compromising its dimensional accuracy.

The Need for Process Control

Sintering is not a single technique. The ideal outcome depends on a careful balance of factors.

Variables like the heat source, the application of external pressure, and the specific material being used all dictate the precise parameters required for a successful result.

Making the Right Choice for Your Goal

Understanding how sintering affects a material allows you to leverage the process to achieve specific engineering outcomes.

- If your primary focus is mechanical performance: Sintering is critical for creating a strong, dense part by eliminating the internal voids that act as failure points.

- If your primary focus is thermal or electrical management: Use sintering to remove insulating air gaps and create a highly conductive final component.

- If your primary focus is optical clarity: Your goal is to achieve maximum densification to reduce light-scattering pores and improve the material's translucency.

- If your primary focus is dimensional accuracy: You must implement precise control over temperature cycles and part support to mitigate the risks of warping and sagging.

Ultimately, mastering the sintering process allows for the deliberate engineering of a material's final properties, starting from a simple powder.

Summary Table:

| Property Affected | Effect of Sintering |

|---|---|

| Porosity | Drastically reduced, leading to densification |

| Mechanical Strength | Significantly increased by eliminating weak points |

| Thermal/Electrical Conductivity | Improved by creating continuous solid paths |

| Translucency (Ceramics) | Enhanced by reducing light-scattering pores |

| Dimensional Accuracy | Can be compromised by warping if not controlled |

Need to achieve precise material properties through sintering? KINTEK specializes in the lab equipment and consumables that ensure your sintering processes deliver optimal density, strength, and conductivity. Let our experts help you select the right furnace and accessories for your specific materials and goals.

Contact our technical team today to discuss your application!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations