For insulation purposes, the most common ceramics are alumina, zirconia, steatite, and mullite. These materials are selected because their tightly bonded crystalline structures resist the flow of either heat or electricity, and in some cases, both. The specific choice depends entirely on the operating temperature, mechanical stress, and whether the primary goal is thermal or electrical insulation.

The term "insulating ceramic" is ambiguous. The critical first step in material selection is to distinguish between the need for thermal insulation (blocking heat) and electrical insulation (blocking current), as the best material for one is often not the ideal choice for the other.

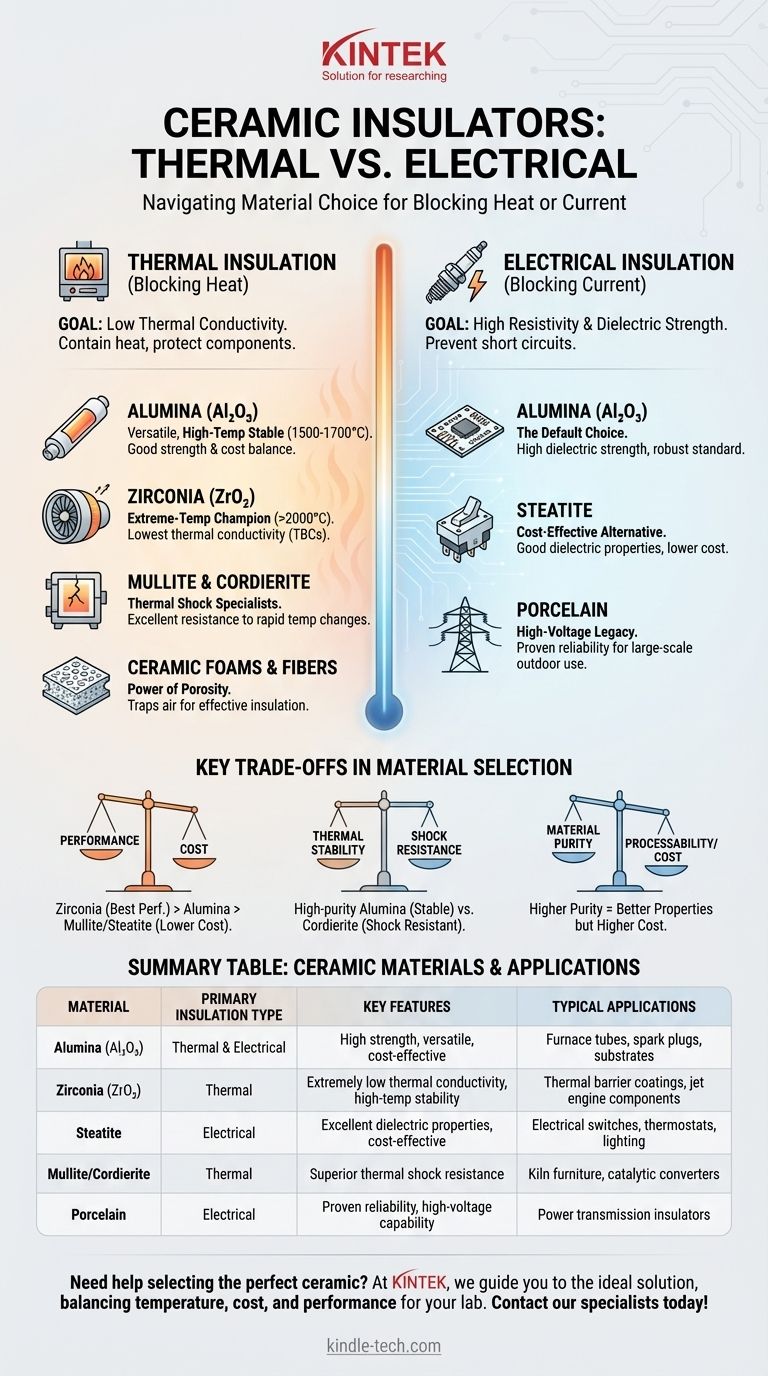

Understanding "Insulation": Thermal vs. Electrical

Before selecting a material, you must define the primary function. Ceramics excel in both domains, but the underlying properties that enable this performance are distinct.

The Goal of Thermal Insulation

The primary property for thermal insulation is low thermal conductivity. This means the material is very poor at transferring heat energy from one side to the other.

This is essential in applications like furnace linings, engine components, and heat shields, where the goal is to contain heat or protect adjacent components from it.

The Goal of Electrical Insulation

For electrical insulation, the key properties are high electrical resistivity and high dielectric strength. These measure the material's ability to resist the flow of electric current and to withstand a high voltage before breaking down.

This is critical for electronic substrates, spark plugs, and high-voltage power line insulators, where preventing short circuits or electrical discharge is the objective.

Key Ceramics for Thermal Insulation

When the goal is to block heat, material choice is driven by maximum temperature, required insulating performance, and resistance to thermal shock.

Alumina (Al2O3): The Versatile Workhorse

Alumina is an excellent thermal insulator that is stable at very high temperatures (typically 1500-1700°C). It balances good performance with reasonable cost and high mechanical strength.

It is frequently used for furnace tubes, thermocouple protection sheaths, and refractory bricks.

Zirconia (ZrO2): The High-Performance Champion

Zirconia has one of the lowest thermal conductivities among all monolithic ceramics, making it a superior insulator at extreme temperatures (often exceeding 2000°C).

Its high cost restricts its use to demanding applications, most notably as Thermal Barrier Coatings (TBCs) on turbine blades in jet engines and gas turbines.

Mullite & Cordierite: The Thermal Shock Specialists

Mullite and Cordierite are aluminosilicate ceramics prized for their excellent thermal shock resistance. Their low coefficient of thermal expansion prevents them from cracking during rapid heating and cooling cycles.

They are the material of choice for kiln furniture, catalyst supports in catalytic converters, and other components that experience drastic temperature fluctuations.

Ceramic Foams & Fibers: The Power of Porosity

For the most effective thermal insulation, form is as important as material. Ceramic fibers, blankets, and foams made from alumina-silica or high-purity alumina are used extensively.

Their effectiveness comes from their porous structure, which traps air (a very poor conductor of heat). The ceramic material provides the high-temperature structural matrix.

Key Ceramics for Electrical Insulation

When blocking current is the goal, resistivity and dielectric strength are paramount.

Alumina (Al2O3): The Default Choice

Just as it is a good thermal insulator, high-purity alumina is an exceptional electrical insulator. Its combination of high dielectric strength, high volume resistivity, and mechanical robustness makes it the standard for many applications.

You will find alumina in spark plug insulators, electronic substrates, and vacuum tube components.

Steatite: The Cost-Effective Alternative

Steatite, a magnesium silicate, offers excellent dielectric properties, especially at high frequencies, but at a lower cost than alumina.

Its trade-off is lower mechanical strength and a lower maximum use temperature. It is widely used for insulators in electrical switches, thermostats, and lighting fixtures.

Porcelain: The High-Voltage Legacy

Traditional electrical porcelain is a mixture of clay (kaolin), feldspar, and quartz. It has been used for over a century for high-voltage applications.

While newer materials offer better performance in some areas, porcelain remains dominant for large-scale, outdoor power transmission insulators due to its proven reliability and low cost.

Understanding the Trade-offs

No material is perfect for every situation. Making an informed decision requires balancing competing factors.

Performance vs. Cost

There is a direct correlation between performance and cost. Zirconia offers the best thermal insulation at the highest temperatures but is significantly more expensive than alumina, which is itself more expensive than mullite or steatite.

Thermal Stability vs. Thermal Shock Resistance

Materials that are extremely stable at very high temperatures (like high-purity alumina) often have higher thermal expansion, making them more susceptible to cracking from thermal shock. Materials designed for shock resistance (like cordierite) often have a lower maximum operating temperature.

Material Purity and Its Impact

The properties of a ceramic are highly dependent on its purity. A 99.8% pure alumina will have substantially better electrical and thermal properties than a 94% pure alumina, but it will also be more difficult to process and more expensive.

Form Factor Limitations

The manufacturing process dictates the available shapes. Some complex geometries are easier and cheaper to produce in steatite via pressing than in high-purity alumina, which may require more expensive machining or injection molding processes.

Making the Right Choice for Your Application

Your final selection must be guided by your primary engineering objective.

- If your primary focus is high-temperature thermal containment (e.g., furnace linings): Begin with alumina for general use and consider mullite if thermal cycling is a major concern.

- If your primary focus is electrical isolation in demanding components: Alumina is the standard starting point due to its excellent all-around properties.

- If your primary focus is surviving rapid temperature changes (thermal shock): Prioritize cordierite or fused silica, accepting their lower mechanical strength and temperature limits.

- If your primary focus is the absolute lowest thermal conductivity at extreme temperatures: Zirconia is the premium choice, especially as a thermal barrier coating.

- If your primary focus is cost-effective electrical insulation for a bulk application: Steatite and traditional porcelain provide excellent value where mechanical and thermal demands are moderate.

By understanding these core properties and trade-offs, you can confidently select the precise ceramic insulator your project demands.

Summary Table:

| Ceramic Material | Primary Insulation Type | Key Features | Typical Applications |

|---|---|---|---|

| Alumina (Al2O3) | Thermal & Electrical | High strength, versatile, cost-effective | Furnace tubes, spark plugs, electronic substrates |

| Zirconia (ZrO2) | Thermal | Extremely low thermal conductivity, high-temp stability | Thermal barrier coatings, jet engine components |

| Steatite | Electrical | Excellent dielectric properties, cost-effective | Electrical switches, thermostats, lighting fixtures |

| Mullite/Cordierite | Thermal | Superior thermal shock resistance | Kiln furniture, catalytic converters |

| Porcelain | Electrical | Proven reliability, high-voltage capability | Power transmission insulators |

Need help selecting the perfect insulating ceramic for your laboratory equipment?

At KINTEK, we specialize in providing high-performance lab equipment and consumables. Our experts can guide you to the ideal ceramic solution—whether you require superior thermal insulation for a furnace or reliable electrical insulation for sensitive instruments. We understand the critical trade-offs between temperature, cost, and performance to ensure your application runs efficiently and safely.

Let us help you optimize your lab's performance. Contact our specialists today for a personalized consultation!

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for Non-Standard Insulator Customization

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

People Also Ask

- How can mechanical damage to an all-PTFE electrolytic cell be prevented? Protect Your Laboratory Hardware

- What technical advantages does a PTFE-based flow reaction platform offer? Speed Up Lignin Depolymerization by 95%

- Are there any chemical substances that an all-PTFE electrolytic cell should not be exposed to? Know the Critical Limits

- What are the primary reasons for selecting PTFE as a matrix? Enhance Composites with Carbon Nanotube Reinforcement

- What functions do PTFE insulation sleeves serve in solid-state battery molds? Enhance Battery Assembly Precision