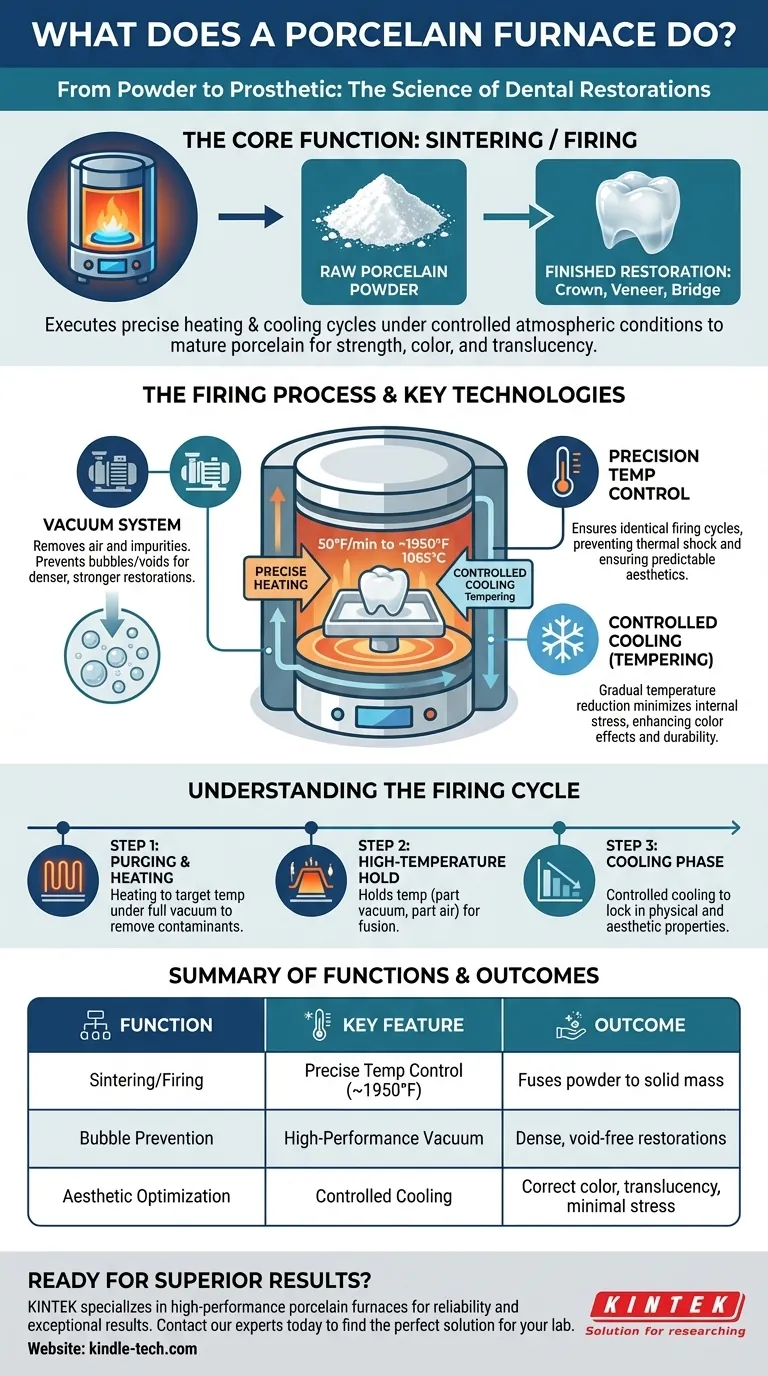

At its core, a porcelain furnace is a highly specialized oven used in dental laboratories to transform raw dental porcelain powder into a finished, durable, and life-like dental restoration. It executes precise heating and cooling cycles under controlled atmospheric conditions to mature the porcelain, ensuring the final crown, veneer, or bridge has the correct strength, color, and translucency.

A porcelain furnace is not merely a heat source; it is a precision instrument. Its primary role is to fuse porcelain particles using a tightly controlled temperature and vacuum cycle, which is essential for creating strong, bubble-free, and aesthetically pleasing dental prosthetics.

The Core Function: From Powder to Prosthetic

A dental porcelain furnace is the critical link between a technician's artistry and a functional dental restoration. Its operation centers on a process known as firing or sintering.

The Refractory Firing Chamber

The main component of the furnace is its refractory firing chamber. This chamber is built with materials capable of withstanding extremely high temperatures without degrading.

Once a dental technician builds up a restoration with porcelain powder, it is placed into this chamber on specialized trays, pins, or meshes that allow for even heating.

The Firing Process

The furnace executes a pre-programmed cycle, carefully raising the temperature at a specific rate (e.g., 50°F per minute) to a high point, often around 1950°F (1065°C).

It holds this temperature for a set time before beginning a controlled cooling phase. This entire process fuses the individual porcelain particles into a solid, vitrified mass.

Achieving Optimal Aesthetics

The goal of firing is to bring the porcelain to optimal maturity. This ensures the final restoration has the desired surface texture, translucency, and color properties, such as hue, chroma, and value. An improper firing cycle can ruin the aesthetic outcome.

Key Technologies That Define Performance

Modern porcelain furnaces incorporate several key technologies to ensure consistent, high-quality results. These features separate them from simple high-temperature ovens.

The Vacuum System

Most of the heating process occurs under a strong vacuum, typically created by an oil-free and water-free pump.

Pulling a vacuum removes air and impurities from between the porcelain particles before they fuse. This critical step prevents bubbles and voids, resulting in a significantly denser and stronger restoration.

Near the end of the cycle, the vacuum is released, and the final hold time is completed in the ambient air of the chamber.

Precision Temperature Control

The furnace must follow the temperature program exactly. Features like temperature compensation help correct for any minor fluctuations, ensuring every firing cycle is identical.

This precision is vital for preventing thermal shock, which can cause cracks, and for achieving predictable aesthetic results every time.

Controlled Cooling (Tempering)

Simply turning off the heat is not an option. High-end furnaces use a tempering cooling (slow cooling) function.

This gradual reduction in temperature minimizes internal stresses within the porcelain, which enhances the final color effects and significantly improves the overall quality and durability of the restoration.

Understanding the Firing Cycle in Practice

A typical firing cycle demonstrates how these technologies work together to produce a final dental restoration.

The Purging and Heating Phase

The cycle begins by heating the furnace from a low temperature to the target high temperature under a full vacuum. This "purging" process removes contaminants.

The High-Temperature Hold

Once the furnace reaches its peak temperature, it holds it for a specific duration. Part of this hold is under vacuum, and the final portion occurs after the vacuum is released into the air.

The Cooling Phase

After the hold, the furnace initiates the controlled cooling sequence. This final step is crucial for tempering the porcelain and locking in its final physical and aesthetic properties.

Making the Right Choice for Your Goal

The features of a porcelain furnace directly impact the quality and efficiency of a dental lab's output.

- If your primary focus is aesthetics and strength: Prioritize a furnace with a high-performance, oil-free vacuum system and precise tempering cooling functions.

- If your primary focus is consistency and reliability: Look for features like automated temperature compensation and durable, low-maintenance components to ensure repeatable results with minimal downtime.

Ultimately, the porcelain furnace is the cornerstone technology for creating dental restorations that are both beautiful and built to last.

Summary Table:

| Function | Key Feature | Outcome |

|---|---|---|

| Sintering/Firing | Precise Temperature Control (up to ~1950°F / 1065°C) | Fuses porcelain powder into a solid, durable mass |

| Bubble Prevention | High-Performance Vacuum System | Creates dense, strong, and void-free restorations |

| Aesthetic Optimization | Controlled Cooling (Tempering) | Achieves correct color, translucency, and minimizes stress |

Ready to achieve superior aesthetic and durable results in your dental lab?

The precision of your porcelain furnace is fundamental to your success. KINTEK specializes in high-performance lab equipment, including advanced porcelain furnaces designed for reliability and exceptional results.

Contact our experts today to find the perfect furnace for your laboratory's needs and ensure every restoration meets the highest standards of quality.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Dental Porcelain Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What temperature is a dental sintering furnace? Mastering the Material-Specific Thermal Cycle

- What methods are used to control the temperature for sintering dental zirconia? Achieve Precise Results with KINTEK

- How are Dental Press Furnaces used with modern dental technologies? Optimize Your CAD/CAM Digital Workflow

- What is the sintering time for zirconia crowns? Master the Trade-Off Between Speed and Strength

- What is the firing temperature of dental ceramics? A Guide to Precise Thermal Processing