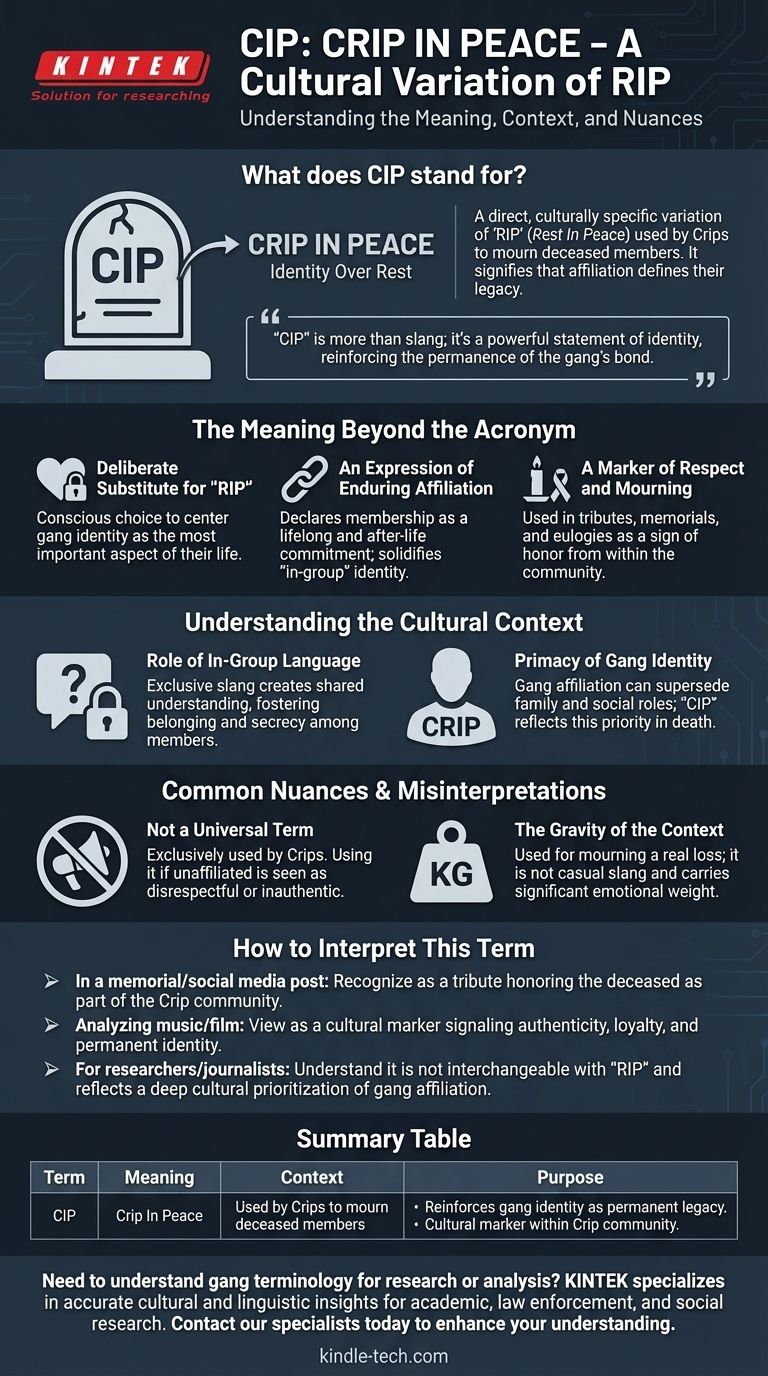

In the context of the Crip gang, the acronym CIP stands for "Crip In Peace." This phrase is a direct variation of the common term "RIP" (Rest In Peace) and is used specifically by members and affiliates of the Crips to mourn and pay respect to a deceased member of their community.

The use of "CIP" instead of "RIP" is more than simple slang; it is a powerful statement of identity. It signifies that a person's affiliation with the Crips was so fundamental that it defines their legacy even in death, reinforcing the permanence of the gang's bond.

The Meaning Beyond the Acronym

Understanding "CIP" requires looking past the literal definition and into the cultural context from which it originates. It is a term deeply rooted in identity, loyalty, and remembrance within a specific community.

A Deliberate Substitute for "RIP"

The replacement of "Rest" with "Crip" is a conscious choice. It serves to center the deceased's gang identity as the most important aspect of their life and legacy. The message is clear: they are not just resting in peace, they are forever a Crip in peace.

An Expression of Enduring Affiliation

The term reinforces the concept that membership is a lifelong, and even after-life, commitment. It declares that the individual lived and died as a Crip and will be remembered as such by their peers. This solidifies the "in-group" identity for both the living and the dead.

A Marker of Respect and Mourning

"CIP" is used in contexts of mourning. You will see it in social media tributes, on memorial t-shirts, in graffiti art, and spoken in eulogies for a fallen member. It is a sign of honor and respect from within the Crip community.

Understanding the Cultural Context

Like any distinct culture, street gangs develop their own dialects, or sociolects, that serve to unify members and distinguish them from outsiders. "CIP" is a prime example of this linguistic practice.

The Role of In-Group Language

Exclusive slang strengthens the bonds within a group. It creates a shared understanding that outsiders may not grasp, fostering a sense of belonging and secrecy. Using "CIP" is a way of speaking directly to the community in a language that is uniquely theirs.

The Primacy of Gang Identity

For many members, gang affiliation can become their primary source of identity, superseding family, neighborhood, or other social roles. The use of "CIP" in death reflects this reality. It prioritizes the identity that the community itself values most highly.

Common Nuances and Misinterpretations

While the meaning is straightforward, the implications of its use are nuanced. It is not a term to be used casually, as it is tied to a specific culture and the serious reality of death.

Not a Universal Term

"CIP" is exclusively used by and for members of the Crip gang. Other gangs have their own distinct slang and memorial customs. Using the term if you are not affiliated is often seen as disrespectful or as falsely claiming a connection you do not have.

The Gravity of the Context

It is critical to remember that "CIP" is used to mourn the dead. It is not casual street slang but a term of remembrance that carries significant emotional weight. It represents a real loss within that community.

How to Interpret This Term

Your goal is not to use the term, but to understand what it signifies when you encounter it.

- If you see 'CIP' in a memorial or social media post: Recognize it as a tribute from within the Crip community, honoring the deceased as one of their own.

- If you are analyzing music or film: View 'CIP' as a specific cultural marker that signals authenticity and underscores themes of loyalty and permanent identity within that world.

- If you are a researcher or journalist: Understand that the term is not interchangeable with 'RIP' and its use reflects a deeply ingrained cultural practice that prioritizes gang affiliation above all else.

Ultimately, language like this provides a crucial window into a community's values, identity, and how it chooses to honor its own.

Summary Table:

| Term | Meaning | Context |

|---|---|---|

| CIP | Crip In Peace | Used by Crips to mourn deceased members |

| RIP | Rest In Peace | Standard memorial phrase |

| Purpose | Reinforces gang identity as permanent legacy | Cultural marker within Crip community |

Need to understand gang terminology for research or analysis? KINTEK specializes in providing accurate cultural and linguistic insights for academic, law enforcement, and social research purposes. Our expertise helps professionals navigate complex subcultures with precision and respect. Contact our specialists today to enhance your understanding of gang culture and terminology.

Visual Guide

Related Products

- Cylindrical Press Mold for Lab Applications

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Manual Lab Heat Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

People Also Ask

- What is the purpose of using a mold for pellet pressing when preparing catalyst test samples? Ensure Data Consistency

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What technical characteristics are required for specialty pressure molds used in the compaction of Li10GeP2S12? Expert Tips

- What does the sample size depend on? Master the 3 Key Factors for Accurate Research

- Is it fitting the mould or mold? A Guide to Correct Spelling by Region