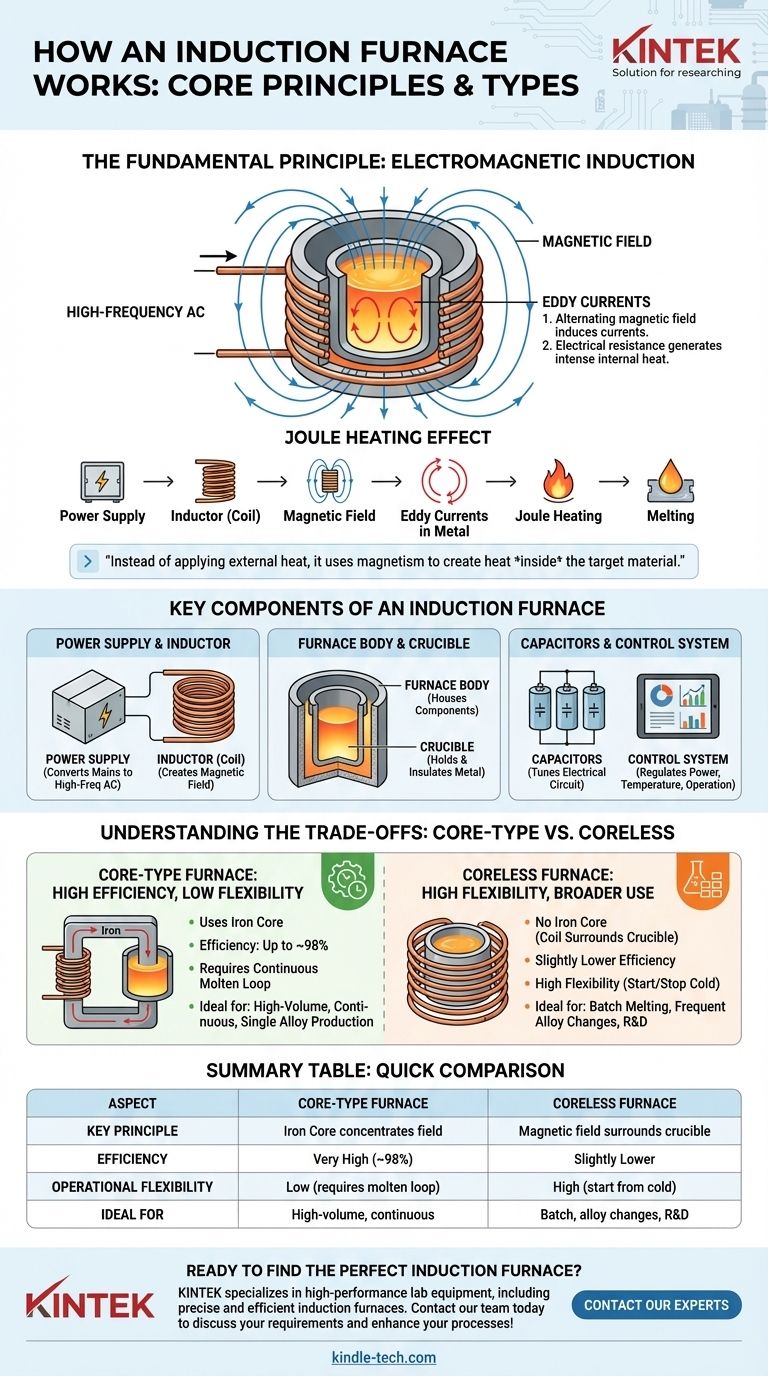

At its core, an induction furnace makes use of the fundamental principle of electromagnetic induction. It uses a powerful, alternating magnetic field to induce electrical currents directly within the conductive material (the metal charge), which in turn generates intense heat due to the material's own electrical resistance. This process turns the metal itself into the heat source.

The central concept to grasp is that an induction furnace is not a conventional oven. Instead of applying external heat, it uses magnetism to create heat inside the target material, resulting in highly efficient, rapid, and controlled melting.

How Induction Heating Works: The Core Principle

To understand an induction furnace, you must first understand the physics it employs. The entire process is a direct application of Faraday's Law of Induction and the Joule heating effect.

The Role of the Inductor (Coil)

The heart of the furnace is a coil of a conductive material, typically a copper tube, through which a high-frequency alternating current (AC) is passed. This current flow generates a powerful and rapidly changing magnetic field in the space within the coil.

Generating Eddy Currents

When a conductive material, like metal scrap or ingots, is placed inside this magnetic field, the field induces circulating electrical currents within the metal. These are known as eddy currents.

Resistance Creates Heat

The metal has inherent electrical resistance. As the strong eddy currents flow against this resistance, they dissipate energy in the form of heat—a phenomenon known as Joule heating. This internal heat generation is what causes the metal to rapidly heat up and eventually melt.

Key Components of an Induction Furnace

An induction furnace is a system of integrated components, each with a critical function. The primary components are the power supply, inductor, and furnace body.

The Power Supply and Inductor

The power supply converts mains electricity into the high-frequency AC required to drive the process. This current is fed into the inductor (or coil), which is responsible for creating the magnetic field.

The Furnace Body and Crucible

The furnace body is the main structure that houses the coil and the crucible. The crucible is a refractory-lined container that holds the metal charge, insulating it from the coil and withstanding the extreme temperatures of the molten metal.

Capacitors and the Control System

A bank of capacitors is used to tune the electrical circuit, maximizing the energy transfer from the power supply to the coil. The control system manages the entire operation, regulating power levels, monitoring temperature, and ensuring safe, consistent performance.

Understanding the Trade-offs: Core-Type vs. Coreless

The design of the furnace significantly impacts its operational characteristics. The two primary designs are core-type and coreless.

Core-Type Furnaces: High Efficiency, Low Flexibility

A core-type furnace uses an iron core to concentrate the magnetic field, linking the primary coil to a loop of molten metal that acts as a secondary circuit. This design is extremely efficient, with power efficiency reaching up to 98%.

However, it must maintain this continuous loop of molten metal to operate. This makes it ideal for high-throughput, continuous operations with few alloy changes, but it cannot be easily shut down or started from cold.

Coreless Furnaces: High Flexibility, Broader Use

The coreless furnace is the more common design, where the crucible containing the charge is placed directly inside the coil without an iron core. While slightly less electrically efficient, its operational flexibility is a major advantage.

Coreless furnaces can be started from cold and completely emptied between melts. This makes them perfectly suited for foundries that require frequent alloy changes, batch production, and flexible operating schedules.

Making the Right Choice for Your Operation

The decision between furnace types is driven entirely by your production goals and operational model.

- If your primary focus is high-volume, continuous production of a single alloy: A core-type furnace offers unmatched electrical efficiency and throughput.

- If your primary focus is batch melting, alloy development, or operational flexibility: A coreless furnace provides the necessary ability to start, stop, and change materials on demand.

Understanding these fundamental principles empowers you to select the technology that best aligns with your specific metallurgical objective.

Summary Table:

| Aspect | Core-Type Furnace | Coreless Furnace |

|---|---|---|

| Key Principle | Uses an iron core to concentrate the magnetic field | No iron core; magnetic field directly surrounds the crucible |

| Efficiency | Very high (up to ~98%) | Slightly lower |

| Operational Flexibility | Low (requires a continuous molten metal loop) | High (can start from cold, be emptied) |

| Ideal For | High-volume, continuous production of a single alloy | Batch melting, frequent alloy changes, R&D |

Ready to find the perfect induction furnace for your lab or foundry? KINTEK specializes in high-performance lab equipment, including induction furnaces for precise and efficient metal melting. Whether you need the high throughput of a core-type or the flexibility of a coreless design, our experts can help you select the ideal solution. Contact our team today to discuss your specific requirements and enhance your metallurgical processes!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- Why is a vacuum hot press furnace preferred for bulk nano-tungsten? Preserving Microstructure via Low-Heat Pressing

- What are the advantages of using a vacuum hot pressing furnace over HIP? Optimize Fiber-Foil Composite Production

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity

- How does the degassing stage in a vacuum hot press (VHP) optimize diamond/aluminum composite performance?