In the context of a location, PVD almost universally stands for Providence, Rhode Island, specifically as the official IATA airport code for Theodore Francis Green Memorial State Airport. While the acronym has a prominent meaning in engineering and manufacturing, if you see it on a flight ticket, map, or travel itinerary, it is pointing to this specific U.S. city.

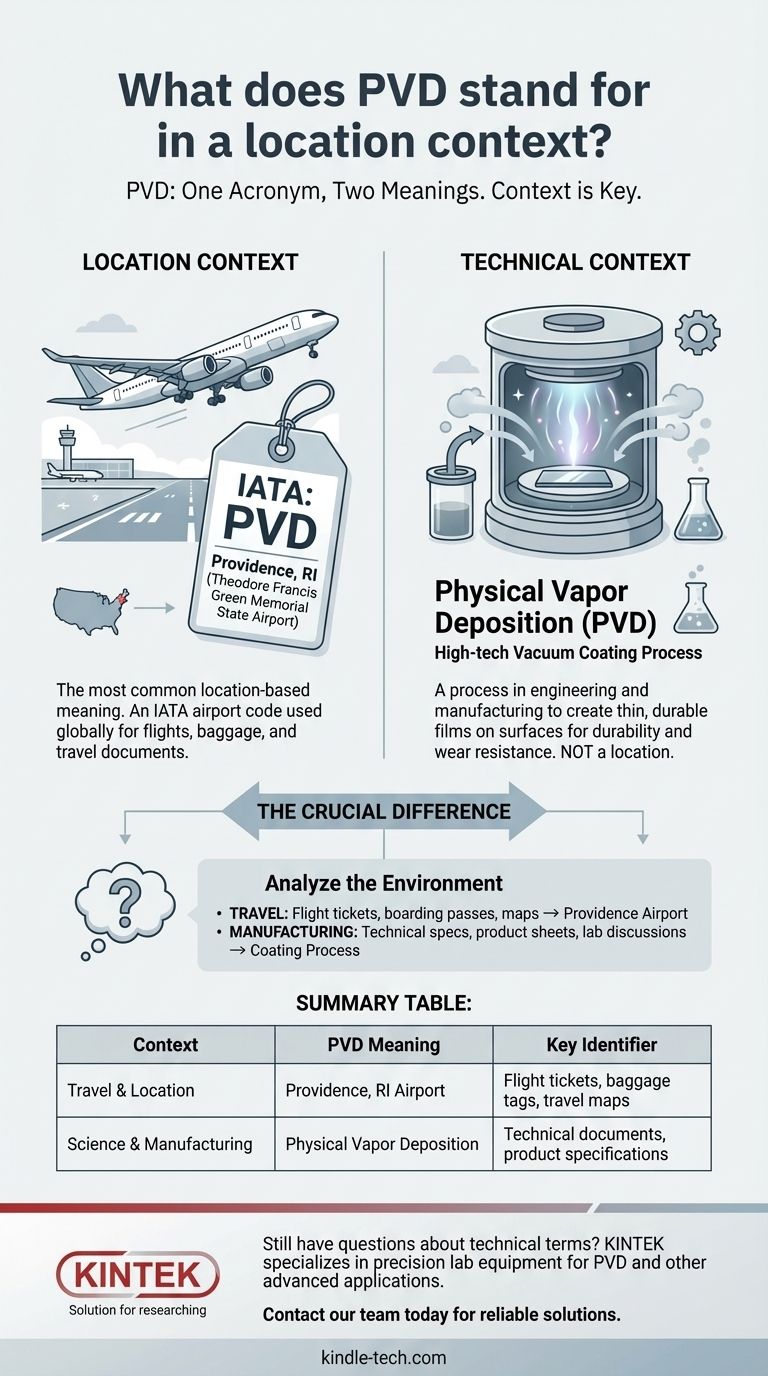

The core of the issue is context. "PVD" is an acronym with two very different, common meanings. For travel and location, it means Providence, Rhode Island; in science and manufacturing, it stands for Physical Vapor Deposition.

The Primary Meaning: PVD as a Location Identifier

When "PVD" is used to refer to a place, it is functioning as a standardized code that simplifies communication in the global travel industry.

The IATA Airport Code

The most common location-based meaning for PVD is its designation as an IATA (International Air Transport Association) code. These three-letter codes are unique identifiers assigned to almost every commercial airport in the world.

PVD is the code for Theodore Francis Green Memorial State Airport, which serves Providence, Rhode Island, and the surrounding New England area.

Why Airport Codes Are Used

These codes are essential for the aviation industry. They appear on baggage tags, flight tickets, and air traffic control systems to ensure there is no ambiguity about departure and destination points. Using "PVD" is faster and more reliable than typing out the full airport or city name.

The Source of Confusion: PVD in Science and Industry

The confusion arises because PVD is also a widely used acronym in technical fields, which has no connection to geography.

Physical Vapor Deposition

In engineering, materials science, and manufacturing, PVD stands for Physical Vapor Deposition. This is a high-tech vacuum coating process used to apply a very thin, durable film onto a surface.

This process involves vaporizing a solid material in a vacuum and depositing it atom by atom onto a substrate. It's used to improve the durability, wear resistance, and appearance of items like medical implants, cutting tools, and even jewelry.

Why This Isn't a Location

Physical Vapor Deposition is a process, not a place. The overlap in acronyms is a common occurrence, where the same set of letters is used to represent entirely different concepts in different fields.

How to Differentiate the Meanings

Disambiguating between the two meanings is entirely dependent on where you encounter the term. Your answer lies in the context surrounding the acronym.

Analyze the Context

If the term PVD appears on a flight itinerary, boarding pass, travel website, or baggage tag, it is referring to the airport in Providence, Rhode Island.

If you see PVD in a technical document, product specification sheet, or a discussion about manufacturing or coatings, it refers to the Physical Vapor Deposition process.

Common Acronym Overlap

This is not a unique problem. Many three-letter acronyms have multiple meanings across different industries (e.g., "AI" can mean Artificial Intelligence or Adobe Illustrator). The key is to always consider the source and subject matter.

Making the Right Interpretation

Your interpretation should always be guided by the environment in which you see the acronym.

- If your primary focus is travel: PVD is the airport code for Providence, Rhode Island (Theodore Francis Green Memorial State Airport).

- If your primary focus is technology or manufacturing: PVD refers to the Physical Vapor Deposition coating technique.

Ultimately, context is the definitive guide to understanding the correct meaning of any acronym.

Summary Table:

| Context | PVD Meaning | Key Identifier |

|---|---|---|

| Travel & Location | Theodore Francis Green Memorial State Airport, Providence, RI | Flight tickets, baggage tags, travel maps |

| Science & Manufacturing | Physical Vapor Deposition (coating process) | Technical documents, product specifications |

Still have questions about technical terms like Physical Vapor Deposition?

At KINTEK, we specialize in precision lab equipment and consumables for manufacturing and research applications. Whether you're working with PVD coatings or other advanced processes, our experts can help you select the right equipment for your laboratory's specific needs.

Contact our team today to discuss how we can support your projects with reliable, high-performance solutions.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the difference between CVD and PVD process? A Guide to Choosing the Right Coating Method

- What is the difference between thermal CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What are the examples of CVD method? Discover the Versatile Applications of Chemical Vapor Deposition

- How is PECVD different from CVD? Unlock Low-Temperature Thin Film Deposition

- What are the advantages of PECVD over CVD? Achieve High-Quality Thin Films at Lower Temperatures