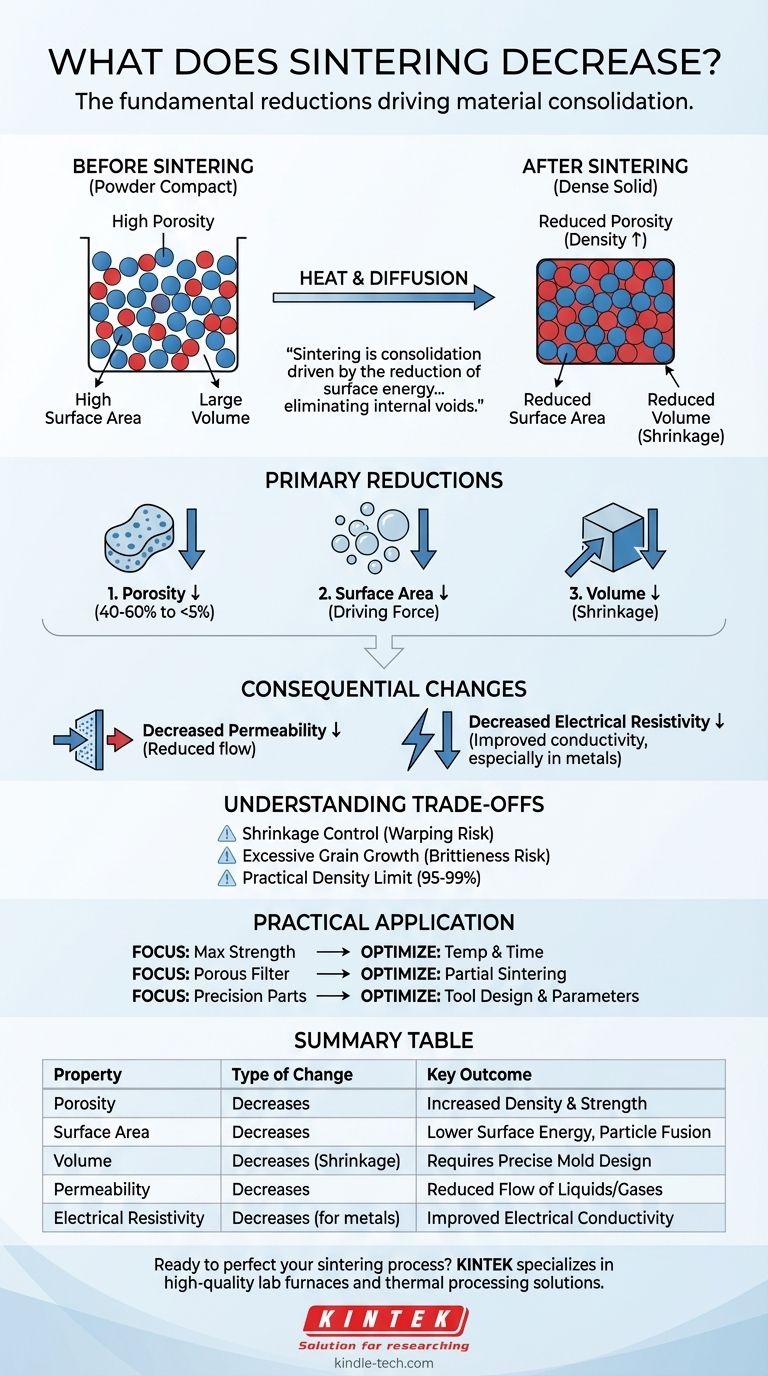

At its core, sintering fundamentally decreases a material's porosity and surface area. This is the primary physical change that occurs when a mass of powder is heated below its melting point. The individual particles fuse together, eliminating the empty spaces (pores) between them and reducing the total exposed surface area of the material.

Sintering is a process of consolidation driven by the reduction of surface energy. By heating a powder compact, you cause particles to bond and grow, systematically eliminating the internal voids and transforming a loose collection of grains into a dense, solid object.

The Primary Reductions Caused by Sintering

Sintering is a transformative process. The decreases it causes are not incidental; they are the very purpose of the procedure, leading directly to the desired final material properties.

The Elimination of Porosity

The most significant change during sintering is the reduction of porosity. The initial powder compact can have a porosity of 40-60%, meaning nearly half its volume is just empty space.

As the material is heated, atoms diffuse across the boundaries of adjacent particles, forming solid "necks" between them. These necks grow, pulling the particles closer and systematically closing the pores, which dramatically increases the material's density.

The Reduction of Surface Area

The fundamental driving force for sintering is the reduction of surface area. A fine powder has an enormous amount of surface area for its mass, which corresponds to a state of high surface energy.

Nature favors lower energy states. By fusing, the small particles reduce their total surface area, just as small soap bubbles merge to form larger ones. This release of excess surface energy is what powers the entire consolidation process.

The Decrease in Overall Volume (Shrinkage)

A direct consequence of eliminating porosity is shrinkage. As the empty spaces between particles are removed, the entire component contracts and its overall volume decreases.

This shrinkage is a critical factor in manufacturing. Engineers must design the initial mold or "green body" to be larger than the final part to compensate precisely for the dimensional changes that will occur during sintering.

Consequential Changes in Material Properties

The primary reductions in porosity and surface area lead to several other important changes in the material's bulk properties.

Decreased Permeability

As the network of interconnected pores is closed off, the material's permeability drops significantly. This makes it more difficult for liquids or gases to pass through.

This property is intentionally controlled. For components like self-lubricating bearings, some porosity is retained to hold oil. For structural parts, the goal is to minimize permeability by eliminating as many pores as possible.

Decreased Electrical Resistivity

For conductive materials like metal powders, sintering typically decreases electrical resistivity. This means the material becomes a better conductor of electricity.

The initial powder compact has poor electrical contact between particles. Sintering creates solid, fused bonds, providing a much more efficient path for electrons to flow, thereby increasing conductivity and decreasing resistance.

Understanding the Trade-offs

While sintering is essential for creating strong materials from powders, the process involves critical trade-offs that must be carefully managed.

The Challenge of Shrinkage Control

Shrinkage is unavoidable but can be difficult to control perfectly. Non-uniform heating or density variations in the initial powder compact can lead to warping or cracking.

Achieving tight dimensional tolerances requires extremely precise control over powder characteristics, compaction pressure, heating rates, and sintering temperature.

The Risk of Excessive Grain Growth

If sintering is performed at too high a temperature or for too long, the grains can continue to grow even after most porosity is gone. This is known as grain growth.

While high density is desirable, excessively large grains can often make a material more brittle, reducing its toughness and strength. The ideal process achieves maximum density while maintaining a fine, strong grain structure.

The Practical Limit of Density

Achieving 100% of a material's theoretical density is often impractical or prohibitively expensive. Some tiny amount of residual porosity almost always remains trapped within the grains.

For most applications, reaching 95-99% of theoretical density is sufficient to achieve the desired mechanical properties.

How to Apply This Knowledge in Practice

Understanding what sintering decreases allows you to control the process to achieve a specific outcome.

- If your primary focus is maximum strength and density: You must optimize the sintering temperature and time to eliminate porosity without causing excessive grain growth.

- If your primary focus is creating a porous filter: You will use partial sintering at lower temperatures or for shorter times to create strong necks between particles while intentionally preserving a network of open pores.

- If your primary focus is manufacturing high-precision parts: You must master the art of predicting and controlling shrinkage through careful tool design and process parameter optimization.

Ultimately, knowing that sintering decreases porosity and surface area gives you the power to engineer a material's microstructure for optimal performance.

Summary Table:

| Property Changed by Sintering | Type of Change | Key Outcome |

|---|---|---|

| Porosity | Decreases | Increased density and strength |

| Surface Area | Decreases | Lower surface energy, particle fusion |

| Volume | Decreases (Shrinkage) | Requires precise mold design |

| Permeability | Decreases | Reduced flow of liquids/gases |

| Electrical Resistivity | Decreases (for metals) | Improved electrical conductivity |

Ready to perfect your sintering process and achieve optimal material properties?

KINTEK specializes in high-quality lab furnaces and equipment for precise thermal processing. Whether you're developing new materials or manufacturing precision components, our solutions help you control porosity, density, and grain structure with exceptional accuracy.

Contact our experts today to discuss how we can support your laboratory's sintering and materials science needs.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What role does high-speed stirring equipment play in fungal pre-cultures? Optimize Your Solid-State Fermentation

- What is one common use for an incubator in a lab? Cultivate Microbiological Cultures for Accurate Analysis

- What products are manufactured with titanium? The Ultimate Guide to High-Performance Materials

- At what temperature will quartz melt? Unlocking Its Complex High-Temperature Journey

- What temperature should Rotavap be? Master the Delta 20 Rule for Safe, Efficient Solvent Removal

- What is the sample KBr ratio for FTIR? Master the 1:100 Ratio for Perfect Pellet Preparation

- What roles do a glass reactor with stirrer and heating mantle play in red mud leaching? Optimize Rare Earth Recovery

- What is the minimum coating thickness? How Steel Thickness Determines Your Galvanizing Needs