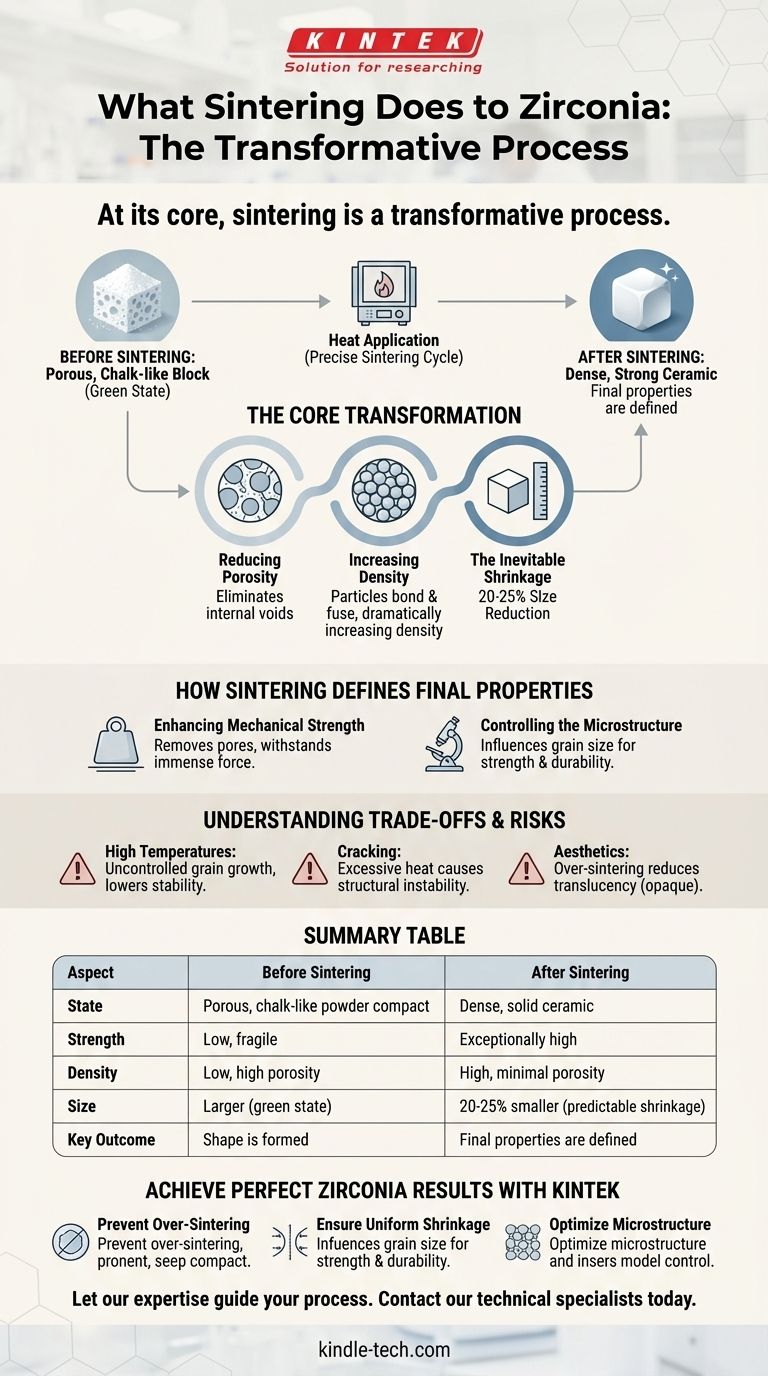

At its core, sintering is a transformative process. It takes a porous, chalk-like block of pre-milled zirconia and, through a precise application of heat, turns it into a dense, incredibly strong ceramic. This is accomplished by causing the individual zirconia particles to fuse, which eliminates internal voids and results in significant, predictable shrinkage of the entire part.

Sintering is not merely a hardening step; it is a fundamental microstructural event that converts a fragile powder compact into a high-performance ceramic. The success of this process directly dictates the final strength, durability, and aesthetics of the zirconia component.

The Core Transformation: From Powder to Solid

The initial, "green state" zirconia is a compressed powder. While it holds a shape, it has no meaningful strength because it is full of microscopic pores between its particles. Sintering fundamentally changes this structure.

Reducing Porosity

The primary goal of sintering is to eliminate the empty spaces, or porosity, within the material. These pores are inherent weaknesses that would lead to immediate fracture under stress.

Increasing Density

As the furnace heats up, the zirconia particles begin to bond and fuse at their contact points. This process closes the pores, pulling the particles closer together and dramatically increasing the material's overall density.

The Inevitable Shrinkage

The direct consequence of eliminating pores and increasing density is a significant and uniform shrinkage of the component. This size reduction, often around 20-25%, is a calculated and essential part of the manufacturing process.

How Sintering Defines Final Properties

The changes at the microscopic level have a profound impact on the final, real-world performance of the zirconia. The quality of the sinter cycle is what unlocks the material's potential.

Enhancing Mechanical Strength

A fully sintered, dense zirconia part has exceptional strength and fracture resistance. By removing the pores, which act as stress concentration points, the material can withstand immense force, making it suitable for demanding applications.

Controlling the Microstructure

The sintering process directly influences the final grain size and grain boundary distribution within the zirconia. A fine, uniform grain structure is typically associated with optimal strength and long-term durability.

Understanding the Trade-offs and Risks

While essential, the sintering process must be executed with precision. Deviations from the ideal protocol can degrade the material rather than improve it.

The Danger of High Temperatures

Sintering zirconia at a temperature that is too high can be counterproductive. It may lead to uncontrolled grain growth, which can paradoxically lower the material's stability and strength.

The Risk of Cracking

Excessive heat or improper temperature ramping can introduce internal stresses. This can result in cracking or structural instability that compromises the integrity of the final part.

The Impact on Aesthetics

Over-sintering is also detrimental to the material's appearance. It can cause a reduction in translucency, making the final product appear opaque or chalky, which is a critical failure in aesthetic applications like dental restorations.

Making the Right Choice for Your Goal

Achieving the desired outcome requires aligning the sintering process with the component's primary requirement.

- If your primary focus is maximum strength: The goal is achieving full densification without excessive grain growth by precisely controlling the peak temperature and hold time.

- If your primary focus is optimal aesthetics: Careful temperature management is critical, as overheating is the primary cause of reduced translucency.

- If your primary focus is consistency and reliability: Strict adherence to the manufacturer's validated sintering cycle is the only way to ensure predictable shrinkage and avoid internal flaws.

Ultimately, mastering the sintering process is what unlocks the remarkable potential of zirconia.

Summary Table:

| Aspect | Before Sintering | After Sintering |

|---|---|---|

| State | Porous, chalk-like powder compact | Dense, solid ceramic |

| Strength | Low, fragile | Exceptionally high |

| Density | Low, high porosity | High, minimal porosity |

| Size | Larger (green state) | 20-25% smaller (predictable shrinkage) |

| Key Outcome | Shape is formed | Final properties are defined |

Achieve Perfect Zirconia Results with KINTEK

Mastering the sintering process is critical to unlocking zirconia's full potential for strength, durability, and aesthetics. Whether you're producing dental restorations, industrial components, or cutting tools, the right equipment ensures precise temperature control for consistent, high-quality outcomes.

KINTEK specializes in advanced laboratory furnaces and consumables designed for the exacting demands of ceramic sintering. Our solutions help you:

- Prevent Over-Sintering: Avoid reduced translucency and weakened stability.

- Ensure Uniform Shrinkage: Achieve predictable and consistent results every time.

- Optimize Microstructure: Develop the fine grain structure needed for maximum strength.

Let our expertise guide your process. Contact our technical specialists today to find the perfect sintering furnace for your laboratory's specific needs and elevate the quality of your zirconia products.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges