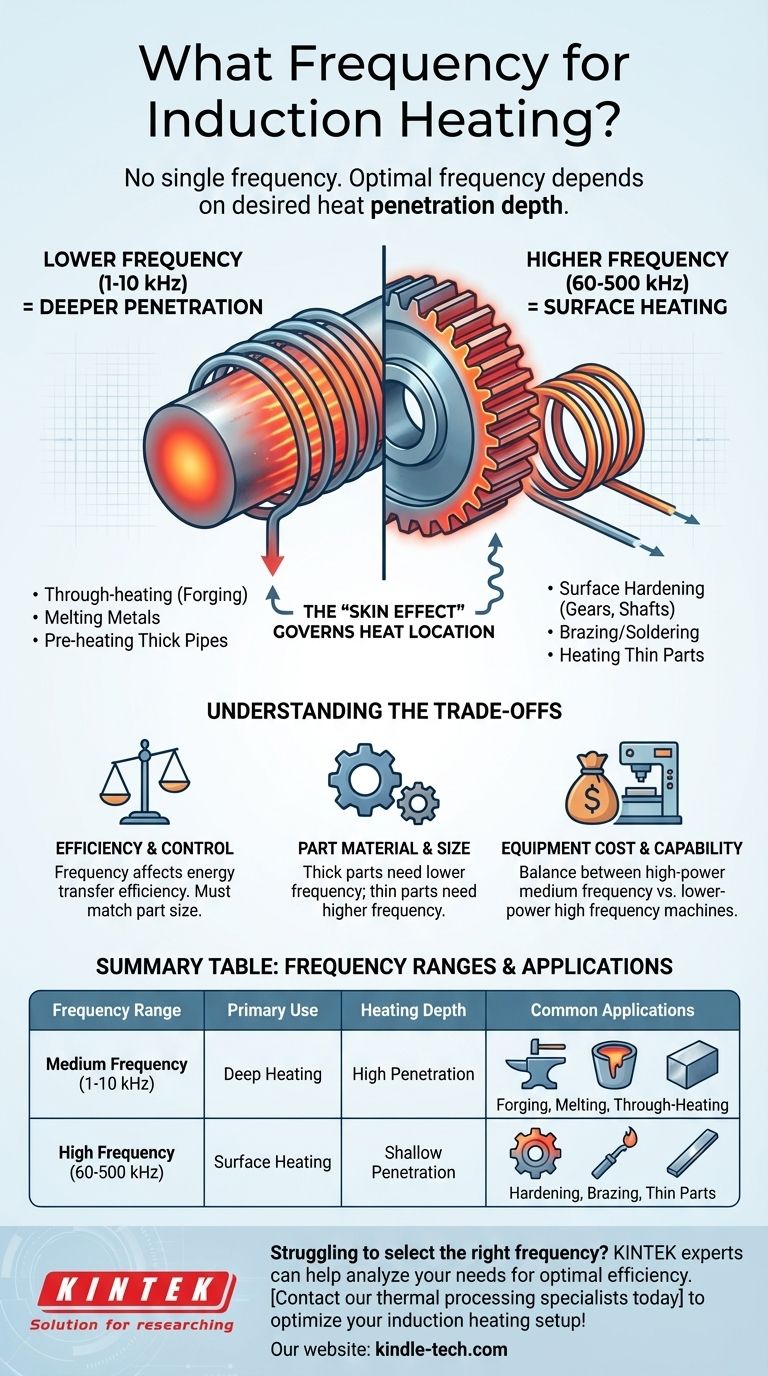

There is no single required frequency for induction heating. Instead, the optimal frequency is determined by the specific application, primarily the desired depth of heat penetration. The process is typically categorized into medium-frequency (roughly 1 to 10 kHz) for deep heating and high-frequency (60 to 500 kHz) for surface-level heating.

The core principle is simple: lower frequencies penetrate deeper into the material, while higher frequencies concentrate heat near the surface. Your choice of frequency is fundamentally a choice about where you want the heat to be generated within your workpiece.

The Fundamental Principle: Frequency vs. Heating Depth

Induction heating is unique because it generates heat inside the object itself, rather than applying it from an external source. An alternating current in a coil creates a magnetic field, which in turn induces eddy currents within the workpiece, generating precise and rapid heat.

The "Skin Effect" Governs Heat Location

The frequency of the alternating current is the most critical variable because it dictates how these eddy currents behave. This phenomenon is known as the "skin effect."

At higher frequencies, the induced current is forced to flow in a thin layer near the surface of the material.

At lower frequencies, the current can penetrate much deeper toward the core of the workpiece.

Low Frequency for Deep Heating (1 - 10 kHz)

A low, or "medium," frequency allows the energy to soak deep into the part. This makes it ideal for applications where the entire mass of the object needs to be heated uniformly.

Common uses include through-heating large billets for forging, melting metals, or pre-heating thick-walled pipes for welding.

High Frequency for Surface Heating (60 - 500 kHz)

A high frequency concentrates the heating effect on the surface, leaving the core of the material relatively cool and unaffected. This is essential when you only want to alter the properties of the surface layer.

This method is perfect for surface hardening of gears and shafts, brazing or soldering joints, and rapidly heating very thin parts.

Understanding the Trade-offs

Selecting a frequency isn't just about depth. It involves a balance of efficiency, cost, and the physical characteristics of the part being heated.

Efficiency and Control

The frequency directly impacts the efficiency of the energy transfer. A frequency that is too low for a small part will be inefficient, as the magnetic field may "miss" the target. A frequency that is too high for a large part will only heat the surface, failing the objective.

Part Material and Size

The material properties and physical dimensions of the workpiece are crucial. A large, thick component requires a lower frequency to allow enough time for the heat to penetrate to the core. A small, thin component requires a higher frequency for rapid, efficient heating without overheating or melting.

Equipment Cost and Capability

The choice of equipment is a practical consideration. In some cases, a very high-power medium-frequency machine might achieve a similar heating effect on a workpiece as a lower-power high-frequency machine. This creates a cost-benefit decision based on your specific process needs.

Making the Right Choice for Your Goal

To select the correct frequency band, you must first define your primary heating objective for the workpiece.

- If your primary focus is through-heating, forging, or melting: Opt for the lower, medium-frequency range (1-10 kHz) to ensure deep and uniform heat penetration.

- If your primary focus is surface hardening, brazing, or heating thin components: Choose a higher frequency (60-500 kHz) to concentrate energy on the surface and protect the core's structural properties.

- If your primary focus is versatility across different part sizes: You must analyze each application individually, as the optimal power and frequency combination will change with the workpiece.

Ultimately, matching the frequency to the required heating depth is the most critical factor in designing a successful and efficient induction process.

Summary Table:

| Frequency Range | Primary Use | Heating Depth | Common Applications |

|---|---|---|---|

| Medium Frequency (1-10 kHz) | Deep Heating | High Penetration | Forging, Melting, Through-Heating |

| High Frequency (60-500 kHz) | Surface Heating | Shallow Penetration | Hardening, Brazing, Thin Parts |

Struggling to select the right frequency for your induction heating process? KINTEK specializes in precision lab equipment and thermal processing solutions. Our experts can help you analyze your material, part size, and heating objectives to recommend the optimal frequency and power settings for maximum efficiency and results.

Contact our thermal processing specialists today to optimize your induction heating setup!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Three-dimensional electromagnetic sieving instrument

- Double Plate Heating Press Mold for Lab

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- Why is a vacuum hot press furnace required for TiAl-based composite preforms? Ensure Purity and Density

- Why is it necessary to maintain a high-vacuum environment within a vacuum hot press furnace? Optimize Cu-SiC Sintering

- What are the advantages of using a vacuum hot pressing furnace over HIP? Optimize Fiber-Foil Composite Production

- What role does hydraulic mechanical pressure play in W-50%Cu vacuum hot press sintering? Achieve 99.6% Density.

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity