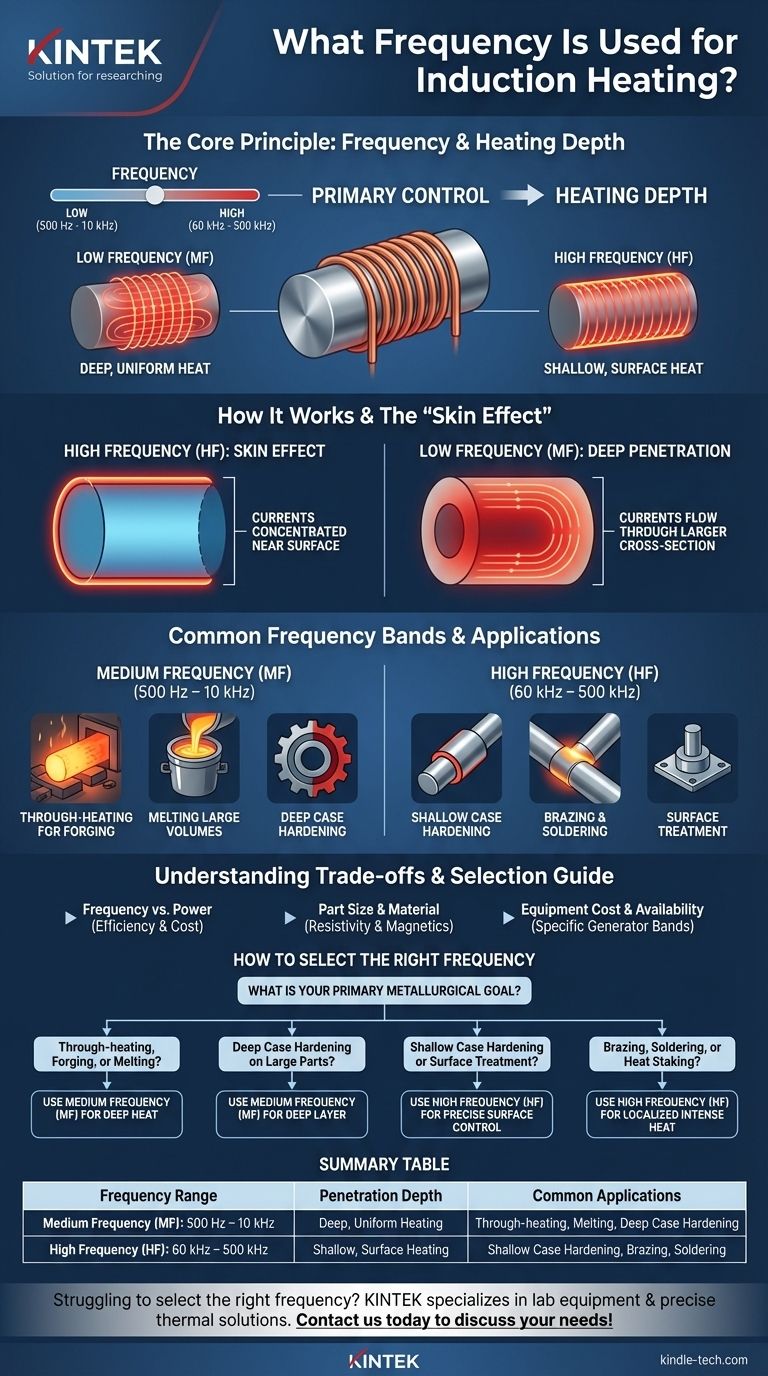

The frequency used for induction heating is not a single value, but rather a range selected based on the specific application. Generally, systems operate in either the Medium Frequency (MF) range of 500 Hz to 10 kHz or the High Frequency (HF) range of 60 kHz to 500 kHz. The choice between these depends entirely on how deep the heat needs to penetrate the material.

The core principle to understand is this: Frequency is the primary control for heating depth. Low frequencies penetrate deeply into a part, while high frequencies concentrate heat near the surface. Selecting the right frequency is about matching it to your desired heating outcome.

The Core Principle: Frequency and the "Skin Effect"

To choose the correct frequency, you must first understand the physics of how it interacts with the material you are heating. This relationship is fundamental to every induction process.

How Induction Heating Works

Induction heating uses a coil to generate a powerful, rapidly alternating magnetic field. When a conductive part (like steel) is placed within this field, it induces electrical currents, known as eddy currents, to flow within the part itself. The material's resistance to these currents generates precise and rapid heat.

The Critical Role of the "Skin Effect"

The frequency of the alternating current dictates where these eddy currents flow. At high frequencies, the currents are forced to flow in a thin layer near the surface of the part. This phenomenon is called the "skin effect."

Conversely, at low frequencies, the magnetic field has more time to penetrate deeper into the material before it reverses, allowing the eddy currents to flow through a much larger cross-section of the part.

Common Frequency Bands and Their Applications

The choice of frequency directly maps to the industrial process you need to perform. Equipment is typically designed to operate within one of two primary bands.

Medium Frequency (MF): 500 Hz – 10 kHz

This lower frequency range is defined by its ability to generate deep and uniform heat. The lower frequency overcomes the skin effect, allowing energy to penetrate far into the workpiece.

This makes MF ideal for applications requiring deep heat, such as through-heating billets for forging, melting large volumes of metal, or creating deep hardened layers on large-diameter parts like gears and shafts.

High Frequency (HF): 60 kHz – 500 kHz

This higher frequency range leverages the skin effect to concentrate energy in a very shallow layer near the surface. The heating is extremely fast and localized.

HF is the standard choice for shallow case hardening, where you need a hard, wear-resistant surface without affecting the core properties of the part. It is also perfect for brazing and soldering, as it can rapidly heat a joint without disturbing the surrounding material.

Understanding the Trade-offs

While frequency is the primary factor for heat depth, it does not exist in a vacuum. Other variables interact with it, creating a system of trade-offs you must consider.

Frequency vs. Power

The heating effect is a function of both frequency and power. For some workpieces, a similar outcome might be achieved with a lower-power, high-frequency system or a higher-power, medium-frequency system. The decision often comes down to efficiency and equipment cost.

Part Size and Material

The physical characteristics of the workpiece are crucial. A very large part may require a lower frequency simply to allow the energy to penetrate to its core effectively. The material's electrical resistivity and magnetic properties also influence how it responds to a given frequency.

Equipment Cost and Availability

Induction heating power supplies are designed to operate within a specific frequency band. A generator built for MF applications cannot be used for HF processes. Therefore, the selection is also a practical consideration based on the equipment required for the job and its associated cost.

How to Select the Right Frequency Range

Your choice should always be driven by the metallurgical outcome you need to achieve. Use the following guidelines to make a decision.

- If your primary focus is through-heating, forging, or melting: Use a lower frequency in the Medium Frequency (MF) range to ensure the entire mass of the part reaches temperature.

- If your primary focus is deep case hardening on large parts: A lower frequency (MF) is required to drive the heat deep enough to create a substantial hardened layer.

- If your primary focus is shallow case hardening or surface treatment: Use a higher frequency in the High Frequency (HF) range for precise control over a thin surface layer.

- If your primary focus is brazing, soldering, or heat staking: A higher frequency (HF) is almost always superior for localizing intense heat at the joint.

By understanding the direct link between frequency and heat depth, you can select the right process for your specific engineering goal.

Summary Table:

| Frequency Range | Penetration Depth | Common Applications |

|---|---|---|

| Medium Frequency (MF): 500 Hz – 10 kHz | Deep, uniform heating | Through-heating for forging, melting, deep case hardening |

| High Frequency (HF): 60 kHz – 500 kHz | Shallow, surface heating | Shallow case hardening, brazing, soldering |

Struggling to select the right induction heating frequency for your process? KINTEK specializes in lab equipment and consumables, providing expert solutions for precise thermal applications. Our team can help you choose the optimal system for deep hardening, brazing, or surface treatments—ensuring efficiency and performance. Contact us today to discuss your specific needs!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

People Also Ask

- What is the maximum temperature for silicon carbide heating element? The Real Limit for Your High-Temp Furnace

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- What are the uses of silicon carbide rod? The Ultimate Heating Solution for Extreme Temperatures

- What material is used for making heating element? Choose the Right Alloy for Your Application

- What is SiC elements? The Ultimate High-Temperature Heating Solution