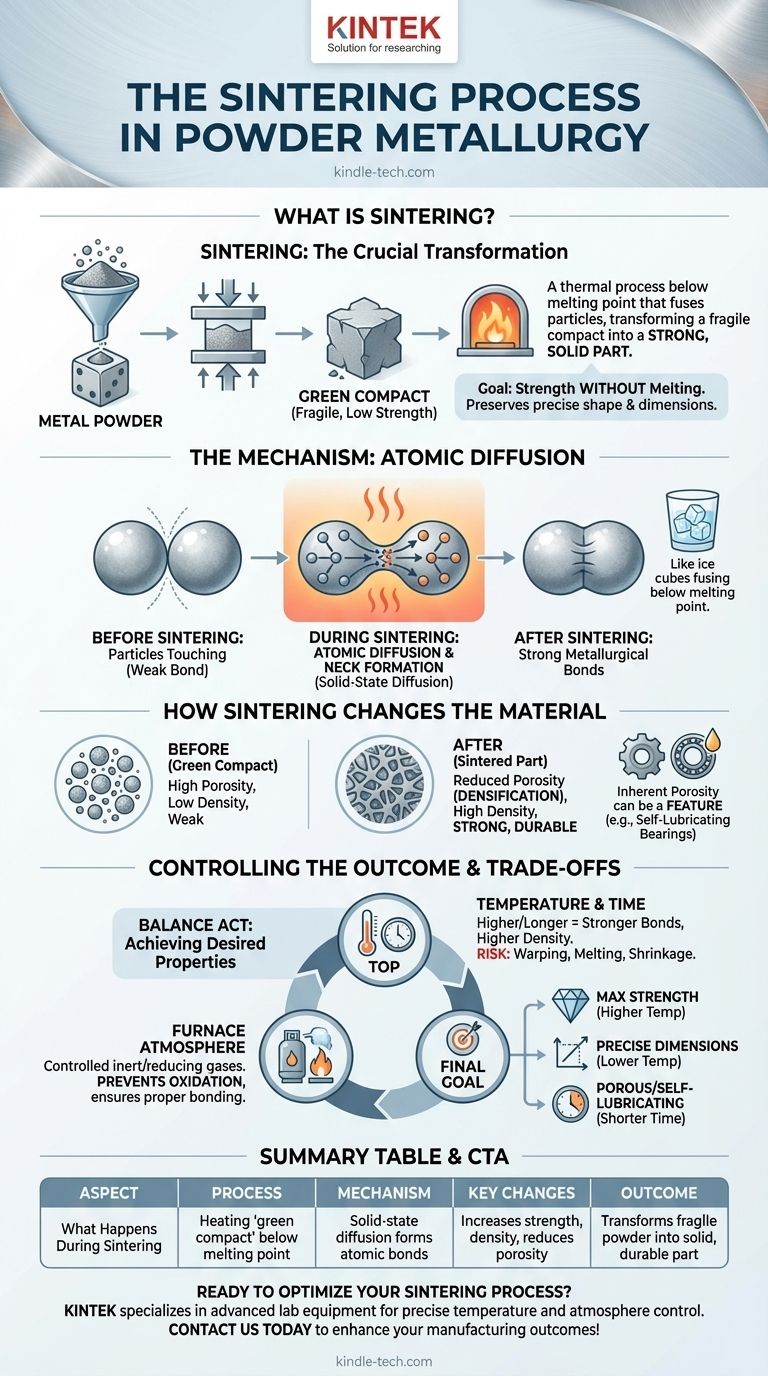

In powder metallurgy, sintering is a thermal process that transforms a fragile, compacted metal powder component into a strong, solid part. This is accomplished by heating the part in a controlled furnace to a temperature just below the material's melting point. This intense heat provides the energy for the individual powder particles to fuse together, creating strong metallic bonds and giving the component its final structural integrity.

A part pressed from metal powder has the right shape but lacks the strength to be useful. Sintering is the critical step that uses heat—without melting—to force these individual particles to bond at an atomic level, creating a dense, durable, and functional component.

The Role of Sintering in Manufacturing

Sintering is the essential bridge between a temporary shape and a permanent, functional part in the powder metallurgy (PM) process. Without it, a PM component would simply crumble.

From a "Green Compact" to a Solid Part

Before sintering, the metal powder is pressed into the desired shape using a die. This initial part is known as a "green compact."

While the green compact has the correct dimensions, it is extremely fragile, held together only by the mechanical interlocking of the powder particles. It has no meaningful strength. Sintering provides the metallurgical bonding needed for structural integrity.

The Goal: Strength Without Melting

The defining characteristic of sintering is that it occurs below the melting point of the primary metal. This is not a casting process.

By avoiding melting, sintering preserves the part's precise shape and dimensional accuracy. It also allows for the creation of unique material alloys and microstructures that would be impossible to achieve through melting and casting.

The Mechanism: Atomic Diffusion

Sintering works through a process called solid-state diffusion. The high heat energizes the atoms at the contact points between the individual powder particles.

These energized atoms migrate across the boundaries, forming "necks" or bridges between adjacent particles. This is similar to how two ice cubes left touching in a glass will slowly fuse into one solid piece, even well below the melting point of water. As these bonds form and grow, the part becomes a single, coherent mass.

How Sintering Changes the Material

The primary changes that occur during sintering are the formation of metallurgical bonds and the reduction of internal voids.

Creating Metallurgical Bonds

The most important function of sintering is to create strong, continuous bonds between what were once separate particles. These bonds are what give the final part its strength, hardness, and toughness.

Increasing Density and Reducing Porosity

The "green compact" is full of tiny empty spaces, or pores, between the powder particles.

During sintering, as atoms diffuse and the particles pull closer together, many of these pores are closed up. This process, called densification, increases the part's density and significantly contributes to its overall strength.

Understanding the Trade-offs

Sintering is a precise balancing act. The final properties of the component are directly controlled by the parameters of the sintering cycle.

Temperature and Time are Critical

The degree of bonding and densification is a function of both temperature and time.

Higher temperatures and longer times in the furnace lead to stronger bonds and higher density. However, if the temperature is too high, the part can warp, shrink uncontrollably, or even begin to melt, destroying its dimensional accuracy.

The Role of Furnace Atmosphere

Sintering is performed in a tightly controlled atmosphere, typically using inert or reducing gases. This is essential to prevent the hot metal from reacting with oxygen.

Oxidation would prevent proper bonding between particles and severely compromise the mechanical properties of the final part.

Inherent Porosity as a Feature or Flaw

While sintering reduces porosity, it rarely eliminates it completely. For high-performance structural parts, this residual porosity can be a limitation, making PM parts slightly less strong than their fully dense, wrought counterparts.

However, this porosity can also be a key design feature. For products like self-lubricating bearings, the interconnected pore network is intentionally preserved and impregnated with oil.

Making the Right Choice for Your Goal

The specific goals of the sintering process directly influence the characteristics and performance of the final component.

- If your primary focus is maximum strength and density: You will need higher sintering temperatures and longer hold times to maximize atomic bonding and minimize internal porosity.

- If your primary focus is preserving precise dimensions: You must use carefully controlled, often lower, temperatures to prevent shrinkage or distortion, even if it means accepting a slightly lower final density.

- If your primary focus is creating a porous, self-lubricating part: You will use lower temperatures or shorter times to create a strong but intentionally interconnected network of pores ready for oil impregnation.

Ultimately, mastering the sintering process is the key to unlocking the unique capabilities of powder metallurgy.

Summary Table:

| Aspect | What Happens During Sintering |

|---|---|

| Process | Heating 'green compact' below melting point to fuse particles. |

| Mechanism | Solid-state diffusion forms atomic bonds (necks) between particles. |

| Key Changes | Increases strength, density, and reduces porosity. |

| Atmosphere | Controlled furnace environment prevents oxidation. |

| Outcome | Transforms fragile powder shape into a solid, durable part. |

Ready to optimize your sintering process for stronger, more precise parts? KINTEK specializes in advanced lab equipment and consumables for powder metallurgy. Our solutions ensure precise temperature control and optimal furnace atmospheres for maximum part integrity. Contact us today to discuss how we can enhance your manufacturing outcomes!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat Sintering Brazing Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What technical functions does a vacuum hot pressing sintering furnace provide? Optimize CoCrFeNi Alloy Coatings

- How does a vacuum environment system contribute to the hot pressing sintering of B4C-CeB6? Unlock Peak Ceramic Density

- What is the primary function of a vacuum hot pressing sintering furnace? Expert Guide for Ti-22Al-25Nb Fabrication