At its core, a muffle furnace is an insulated oven designed to heat materials to extremely high temperatures in a highly controlled environment. It achieves this by using a "muffle"—a refractory chamber—that isolates the sample from the heating elements, ensuring the material is not contaminated by combustion byproducts and is heated uniformly.

The defining characteristic of a muffle furnace is its use of indirect heat. The sample never touches the heating source, which guarantees thermal uniformity and prevents chemical contamination, making it essential for precise material testing and treatment.

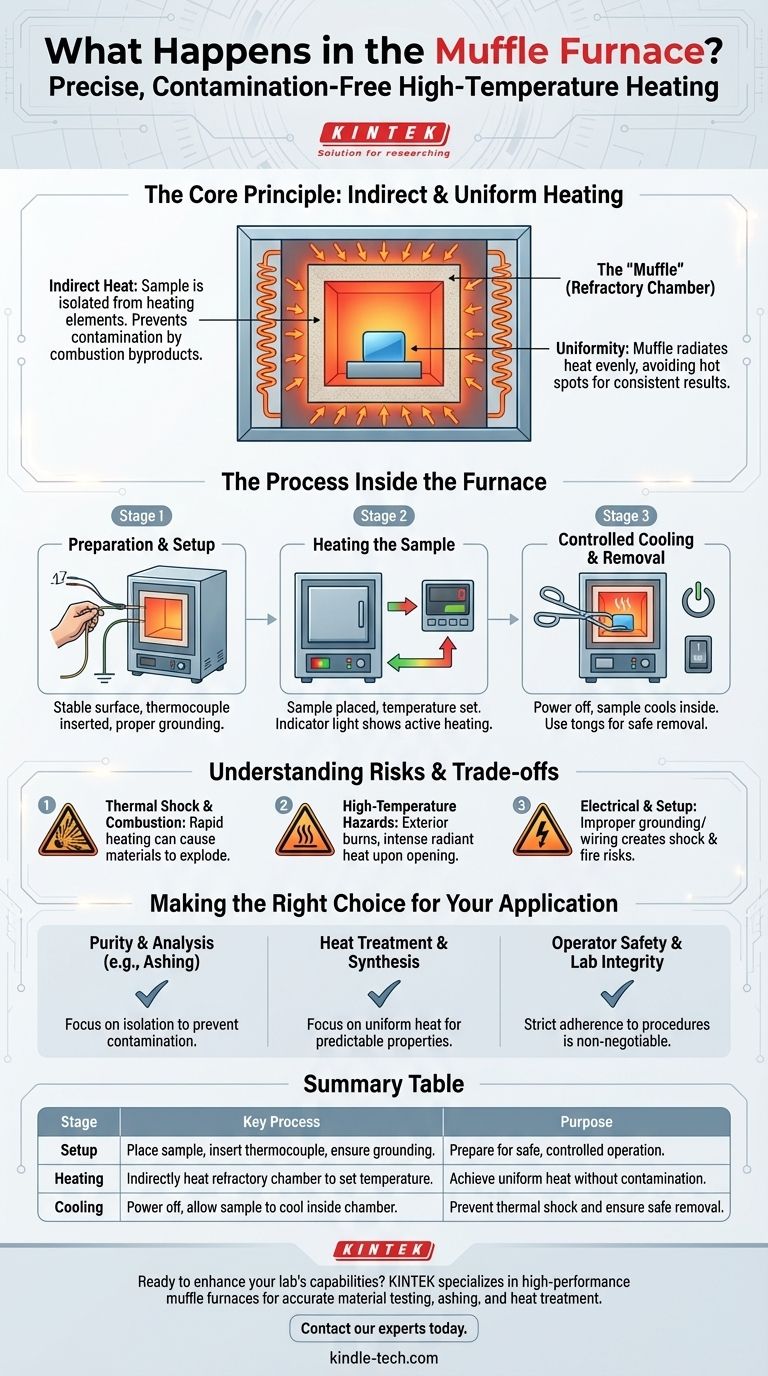

The Core Principle: Indirect and Uniform Heating

To understand what happens inside a muffle furnace, you must first understand its design. Unlike a simple oven, its primary function is to create a pure and even heating environment.

What is the "Muffle"?

The term "muffle" refers to the furnace's inner chamber, which is constructed from high-temperature-resistant refractory materials. This chamber encloses the sample being heated.

The heating elements are located outside this muffle, heating the chamber from all sides rather than heating the sample directly.

Preventing Contamination

A primary purpose of this design is to shield the workpiece from the byproducts of combustion or direct radiation from the heating elements.

This isolation is critical for processes like ashing, quantitative analysis, or creating high-purity materials where any external contamination would invalidate the results.

Ensuring Temperature Uniformity

By heating the chamber's exterior, the furnace avoids the "hot spots" common in industrial furnaces where one side is hotter than the other.

The insulating muffle radiates heat evenly inward, ensuring the entire sample experiences the same temperature. This uniformity is vital for consistent material heat treatment.

The Process Inside the Furnace

A typical operation involves several distinct stages, from initial setup to the final removal of the treated sample.

Preparation and Setup

Before use, the furnace is placed on a stable surface. A thermocouple, which measures temperature, is inserted into the furnace chamber and connected to an external controller.

Proper grounding and a dedicated power switch are installed to ensure electrical safety. The controller is kept away from the furnace body to prevent it from overheating.

Heating the Sample

Once the sample is placed inside the muffle, the door is closed, and the desired temperature is set on the controller. The system then activates the heating elements.

An indicator light, often green, shows that the furnace is actively heating. When the set temperature is reached, the light typically changes (e.g., to red) to indicate it is now holding a constant temperature.

Controlled Cooling and Removal

After the process is complete, the power is turned off. The sample is left inside to cool down to a safe temperature before the furnace door is opened.

Operators must use appropriate tools, like tongs, to carefully remove the hot sample to prevent severe burns.

Understanding the Risks and Trade-offs

While powerful, a muffle furnace operates at extreme temperatures and presents significant hazards if not used correctly.

Risk of Thermal Shock and Combustion

Some materials, such as pellets, can combust or even explode upon contact with the extremely hot interior surfaces. This can cause a sudden temperature spike and damage the furnace or the sample.

High-Temperature Hazards

The exterior of the furnace can become hot enough to cause burns. More critically, opening the door while the furnace is at temperature can expose the operator to intense radiant heat.

Heated particles can also escape the muffle when opened, potentially damaging the surrounding area or creating a fire hazard.

Electrical and Setup Considerations

Improper setup is a major source of risk. Failing to ground the furnace and controller can lead to electrical shock.

Likewise, poor wiring or the lack of a dedicated power switch can create a fire or electrical hazard, especially given the high power consumption.

Making the Right Choice for Your Application

The key to using a muffle furnace effectively is aligning its capabilities with your specific goal.

- If your primary focus is material purity and analysis (e.g., ashing): The muffle's isolation is its most important feature, as it prevents sample contamination.

- If your primary focus is heat treatment or material synthesis: The furnace's ability to provide uniform, consistent heat is critical for achieving predictable material properties.

- If your primary focus is operator safety and lab integrity: Strict adherence to setup, operation, and cooling procedures is non-negotiable to prevent injury and damage.

Ultimately, a muffle furnace is a precision instrument for achieving pure and uniform high-temperature conditions.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| Setup | Place sample, insert thermocouple, ensure grounding | Prepare for safe, controlled operation |

| Heating | Indirectly heat refractory chamber to set temperature | Achieve uniform heat without contamination |

| Cooling | Power off, allow sample to cool inside chamber | Prevent thermal shock and ensure safe removal |

Ready to enhance your lab's capabilities with precise, contamination-free heating?

KINTEK specializes in high-performance muffle furnaces and lab equipment, providing the reliable tools you need for accurate material testing, ashing, and heat treatment. Our solutions ensure uniform temperatures and sample purity, critical for your research and quality control.

Contact our experts today to find the perfect muffle furnace for your application!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is muffle furnace working principle and application? Achieve Contamination-Free High-Temperature Processing

- What is the difference between cold type and hot type? Uncover the Printing Revolution

- What is the difference between a muffle furnace and a drying oven? Choose the Right Thermal Tool

- What is the main function of a muffle furnace? Achieve Pure, High-Temperature Processing

- Is a muffle furnace an oven? A Guide to High-Temperature vs. Low-Temperature Heating