In a vacuum, heat transfer occurs almost exclusively through thermal radiation. This is because the other two modes of heat transfer, conduction and convection, require a physical medium to transfer energy. Since a vacuum is a space devoid of matter, radiation is the only mechanism available for heat to travel from one object to another.

A vacuum is the ultimate insulator against conduction and convection. Therefore, any heat transfer that occurs within it—whether for heating an object or insulating it—is entirely governed by the principles of thermal radiation, making surface properties paramount.

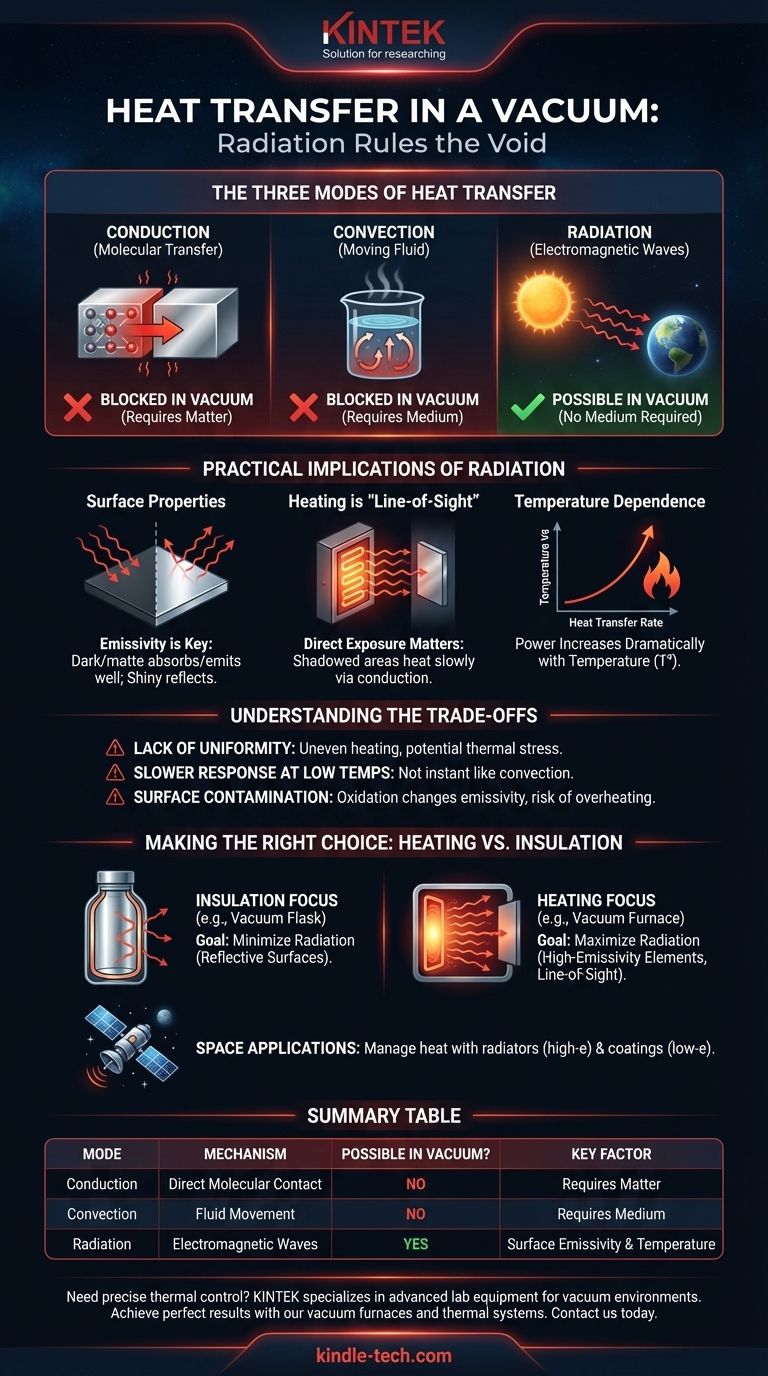

The Three Modes of Heat Transfer

To understand why radiation is the only method that works in a vacuum, it's essential to quickly review all three modes of heat transfer.

Conduction: The Molecular Transfer

Conduction is heat transfer through direct contact. Hot, rapidly vibrating atoms and molecules bump into their cooler, slower neighbors, transferring kinetic energy directly.

This process requires matter. In a perfect vacuum, there are no molecules to collide, so conduction is completely eliminated.

Convection: The Moving Fluid

Convection is heat transfer through the movement of fluids (liquids or gases). A heated fluid becomes less dense and rises, while cooler, denser fluid sinks, creating a current that circulates heat.

This process also requires a medium. With no air or other fluid to move, convection cannot occur in a vacuum.

Radiation: The Unimpeded Wave

Thermal radiation is the transfer of heat in the form of electromagnetic waves, primarily in the infrared spectrum. All objects with a temperature above absolute zero emit these waves.

Unlike conduction and convection, radiation does not require any medium to propagate. This is how the sun's heat travels 93 million miles through the vacuum of space to warm the Earth.

Practical Implications of Radiation in a Vacuum

Because radiation is the only mechanism at play, the rules for managing heat in a vacuum are fundamentally different from those in a normal atmosphere.

Surface Properties Are Critical

The rate of radiative heat transfer is determined by an object's temperature and a surface property called emissivity.

A dark, matte surface has high emissivity, meaning it is very effective at both emitting and absorbing radiation. A shiny, reflective surface has low emissivity, making it a poor emitter and absorber. This is why emergency space blankets are reflective—to minimize radiative heat loss from the body.

Heating is "Line-of-Sight"

In a conventional oven, convection currents help distribute heat evenly around an object. In a vacuum furnace, heating is primarily "line-of-sight."

The heating element radiates energy directly to the surfaces of the workpiece it can "see." Areas in shadow will not heat as quickly, relying on slow conduction through the material itself to reach temperature.

Temperature Determines Effectiveness

The amount of energy transferred by radiation increases dramatically with temperature (specifically, to the fourth power of the absolute temperature).

This makes radiation an extremely effective heating method at high temperatures, as seen in vacuum induction sintering. However, at lower temperatures, the rate of heat transfer is significantly less, which can make heating processes slower.

Understanding the Trade-offs

Relying solely on radiation introduces unique challenges that are not present when conduction and convection are available.

Lack of Uniformity

Achieving uniform heating can be difficult. Without air to distribute thermal energy, any part of a workpiece not directly exposed to the radiation source will lag in temperature, potentially creating thermal stresses within the material.

Slower Response at Low Temperatures

While powerful at high temperatures, radiative heating can be slow to start at ambient or low temperatures. This is a key consideration in applications like vacuum freeze-drying, where precise and gentle temperature control is needed.

Surface Contamination

The emissivity of a surface can be drastically changed by a thin layer of oxidation or contamination. A clean, shiny piece of metal may have low emissivity, but if it oxidizes during heating, its emissivity will increase, causing it to absorb heat much faster and potentially overheat.

Making the Right Choice for Your Goal

Your approach to managing heat in a vacuum depends entirely on whether your goal is to heat something up or to keep it insulated.

- If your primary focus is insulation (e.g., a vacuum flask, cryogenics): Your goal is to minimize radiative heat transfer by using highly reflective, low-emissivity surfaces between the vacuum gaps.

- If your primary focus is heating (e.g., a vacuum furnace): You must maximize radiative transfer by using high-emissivity heating elements and carefully designing the geometry to ensure good "line-of-sight" exposure to the workpiece.

- If your primary focus is space applications (e.g., a satellite): You must actively manage heat by using radiators (high-emissivity surfaces) to shed waste heat into space and reflective coatings (low-emissivity surfaces) to block incoming solar radiation.

Ultimately, mastering heat transfer in a vacuum is about mastering the control of thermal radiation.

Summary Table:

| Mode of Heat Transfer | Mechanism | Possible in Vacuum? | Key Factor |

|---|---|---|---|

| Conduction | Direct molecular contact | No | Requires a physical medium |

| Convection | Movement of fluids (air/liquid) | No | Requires a fluid medium |

| Radiation | Electromagnetic waves (infrared) | Yes | Depends on surface emissivity & temperature |

Need precise thermal control for your lab processes?

At KINTEK, we specialize in advanced lab equipment designed for optimal heat management in vacuum environments. Whether you're working with high-temperature sintering, material testing, or specialized insulation, our vacuum furnaces and thermal systems deliver unmatched performance and reliability.

Let our experts help you achieve perfect results:

Contact us today to discuss your specific laboratory needs and discover how KINTEK's solutions can enhance your research and production efficiency.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- How does vacuum coating work? Achieve Superior Surface Properties with PVD Technology

- What are the advantages and disadvantages of sintering? A Guide to High-Performance Powder Processing

- What is the temperature of pyrolysis? A Guide to Controlling Product Yields

- What are the working principles of furnace? A Guide to Combustion, Resistance, and Induction Heating

- Why is vacuum created in the chamber before thermal evaporation? For High-Quality, Uniform Thin Films

- What is the primary function of a vacuum drying oven for NH4H2PO4-coated NCM811? Optimize Your Battery Precursor Prep

- Why are vacuum drying ovens essential for health monitoring sensors? Ensure Superior Stability and Biological Safety

- What is the critical function of high vacuum in Pr3+:CaF2 ceramic preparation? Achieving Optical-Grade Transparency