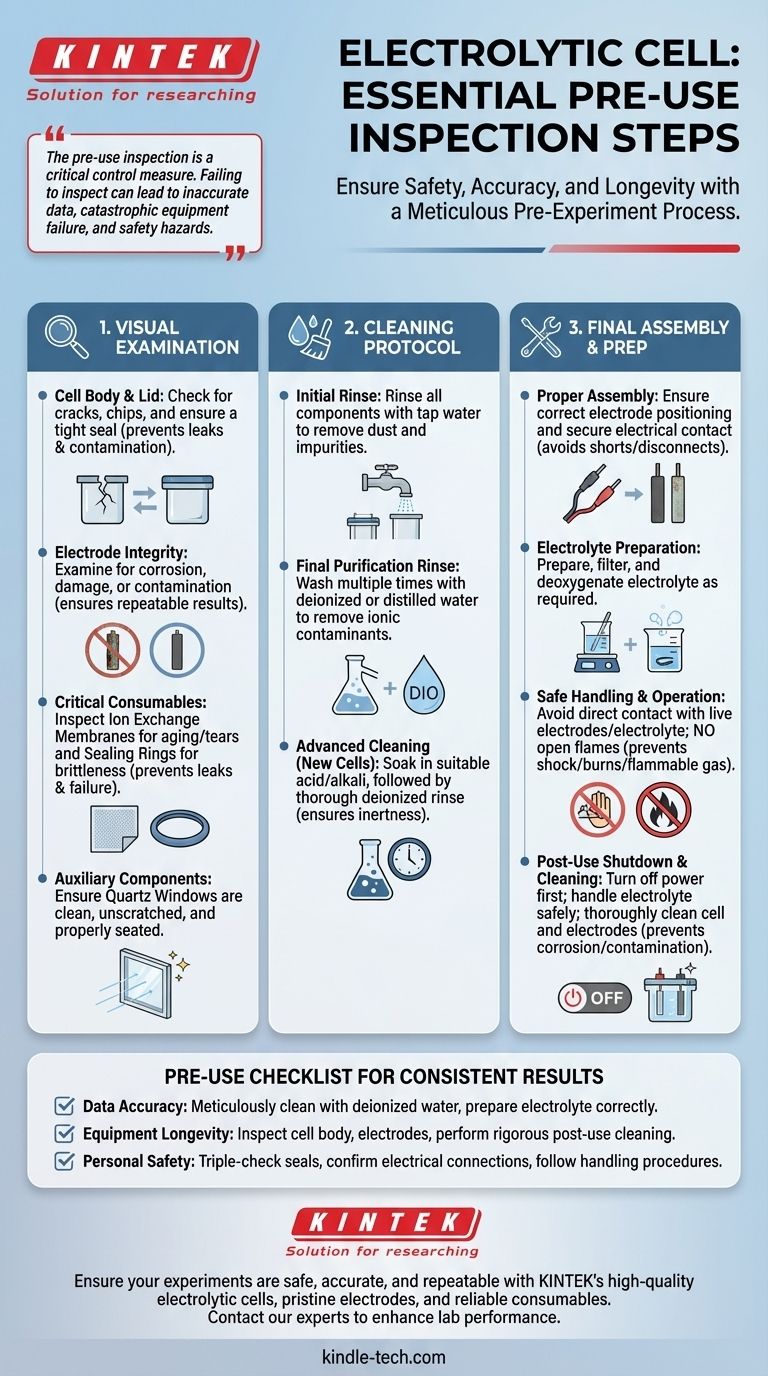

Before any experiment, a meticulous pre-use inspection of an electrolytic cell involves three core phases: a thorough visual examination of all components for damage, a rigorous cleaning protocol to remove contaminants, and a final check of the assembly and electrolyte preparation. This systematic process is essential for ensuring the safety of the operator, the accuracy of the results, and the longevity of the equipment.

The pre-use inspection is not merely a procedural step; it is a critical control measure. Failing to properly inspect and prepare your electrolytic cell can lead to inaccurate data, catastrophic equipment failure, and significant safety hazards.

The Foundational Inspection: A Component-by-Component Review

The first step is a physical audit of every part of the cell. This systematic review ensures the structural and chemical integrity of the entire apparatus before you begin.

Inspecting the Cell Body and Lid

The cell body is the primary containment vessel. Carefully check it for any cracks, chips, or leaks, as these can compromise the experiment and create a safety risk.

Ensure the lid forms a tight and secure seal with the body. A poor seal can lead to electrolyte leakage or contamination from the surrounding atmosphere.

Verifying Electrode Integrity

The electrodes are the heart of the cell where the electrochemical reactions occur. Examine their surfaces for any signs of corrosion, physical damage, or contamination.

An oxidized or contaminated electrode surface will yield unreliable and non-repeatable results. The surface must be clean and in pristine condition to ensure accurate measurements.

Assessing Critical Consumables

Pay special attention to components that degrade over time, such as the ion exchange membrane and sealing rings.

Inspect the membrane for any signs of aging, discoloration, blockage, or physical tears. Check sealing rings for brittleness or damage. Damaged consumables are a primary cause of leaks and experimental failure and should be replaced immediately.

Checking Auxiliary Components

If your cell includes other parts, like quartz windows for spectroscopic analysis, ensure they are clean, unscratched, and properly seated.

The Critical Cleaning Protocol

Contaminants are the enemy of accurate electrochemical work. A multi-stage cleaning process is non-negotiable.

Initial Rinse

Begin by rinsing all cell components with tap water. This simple step effectively removes surface dust and loose impurities.

Final Purification Rinse

Follow the initial rinse by washing all parts multiple times with deionized or distilled water. This removes any residual ionic contaminants from the tap water that could interfere with your electrolyte.

Advanced Cleaning for New Cells

A brand-new electrolytic cell often has residual oils or other contaminants from the manufacturing process. It may be necessary to soak it in a suitable acid or alkali solution, followed by a thorough rinse with deionized water, to ensure it is completely inert.

Understanding the Risks and Best Practices

A pre-use inspection is fundamentally about mitigating risk. Understanding the potential failures informs the entire process, from setup to shutdown.

The Importance of Proper Assembly

During assembly, ensure electrodes are positioned correctly and have good electrical contact. Secure wiring is critical to prevent accidental shorts or disconnects during the experiment.

Safe Handling During Operation

Once the experiment begins, avoid all direct contact with live electrodes and the electrolyte to prevent the risk of electric shock or chemical burns. Never use open flames or other ignition sources near the cell, as some electrolytic processes can produce flammable gases.

The Post-Use Shutdown and Cleaning

Proper shutdown procedure is as important as setup. Always turn off the power supply first before disconnecting any part of the circuit.

After the experiment, the electrolyte must be handled according to safety and environmental protocols. Promptly and thoroughly clean the cell and electrodes to remove all reaction products, preventing long-term corrosion and contamination for future use.

A Pre-Use Checklist for Consistent Results

Your specific priorities will determine which inspection points require the most attention. Use this guide to focus your preparation.

- If your primary focus is data accuracy: Meticulously clean all components with deionized water and ensure your electrolyte is properly prepared, filtered, and deoxygenated as required.

- If your primary focus is equipment longevity: Pay closest attention to inspecting the cell body for cracks, the electrodes for corrosion, and performing rigorous post-use cleaning to prevent degradation.

- If your primary focus is personal safety: Triple-check all seals and the cell body for any potential leaks, confirm all electrical connections are secure, and always follow proper handling procedures.

Ultimately, disciplined and thorough preparation is the foundation of all successful and repeatable electrochemical work.

Summary Table:

| Inspection Phase | Key Actions | Purpose |

|---|---|---|

| Visual Examination | Check cell body/lid for cracks/leaks; inspect electrodes for damage; assess consumables (membranes, seals). | Ensure structural integrity and component reliability. |

| Cleaning Protocol | Rinse with tap water; purify with deionized water; perform advanced cleaning for new cells. | Eliminate contaminants for accurate results. |

| Final Assembly & Prep | Verify secure assembly and electrical connections; prepare electrolyte correctly. | Mitigate safety risks and ensure operational readiness. |

Ensure your electrochemical experiments are safe, accurate, and repeatable with the right equipment and consumables. KINTEK specializes in high-quality lab equipment, including durable electrolytic cells, pristine electrodes, and reliable consumables like ion exchange membranes and sealing rings, designed to meet the rigorous demands of your laboratory. Don't let equipment failure compromise your research—contact our experts today to find the perfect solutions for your specific needs and enhance your lab's performance and safety.

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell with Five-Port

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- H Type Electrolytic Cell Triple Electrochemical Cell

People Also Ask

- When is professional repair required for a double-layer water-bath electrolytic cell? Protect Your Lab's Precision and Safety

- What are the standard aperture specifications of the electrolytic cell? Key Sizes for Your Electrochemical Setup

- What are the typical volumes and aperture configurations for a double-layer water-bath electrolytic cell? Optimize Your Electrochemical Setup

- What are the key features of a double-layer water-bath electrolytic cell? Achieve Precise Temperature Control for Your Experiments

- What are the standard aperture sizes on the lid of the multifunctional electrolytic cell? Key Ports for Your Electrochemical Setup