A 1800°C furnace is a specialized piece of high-temperature equipment designed for the thermal processing of advanced materials that require extreme heat. These furnaces are distinct from more common models due to the unique materials and engineering needed to safely and reliably reach and maintain temperatures that can melt many metals, including steel.

The defining characteristic of a 1800°C furnace isn't just its high temperature rating, but the specialized components required to operate in such an extreme environment. Understanding these components—like Molybdenum Disilicide heating elements and high-purity alumina insulation—is the key to understanding the furnace's true capabilities and limitations.

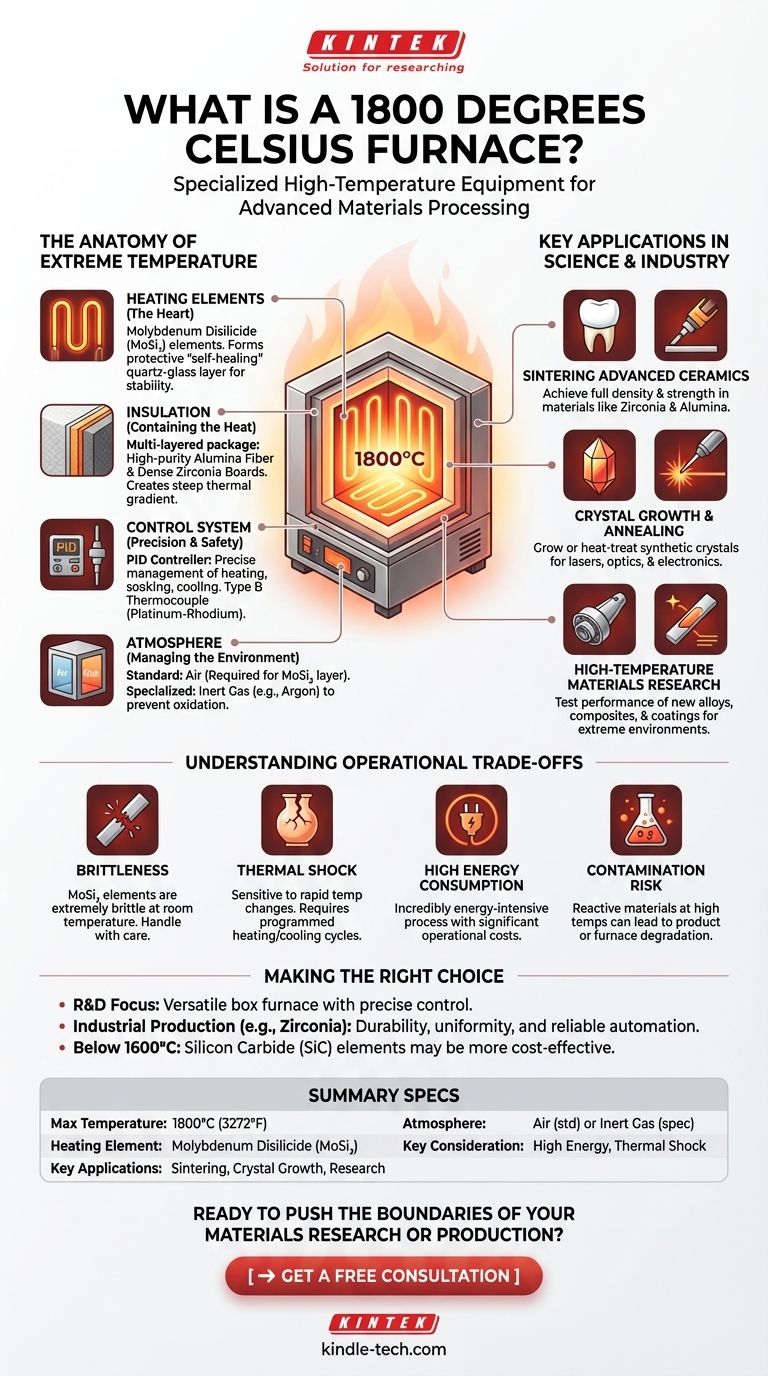

The Anatomy of an Extreme-Temperature Furnace

Reaching and containing 1800°C (approx. 3272°F) is a significant engineering challenge. The design and materials of every component are critical for performance, safety, and longevity.

The Heart of the Furnace: Heating Elements

The single most important component is the heating element, as common materials fail long before 1800°C.

These furnaces almost exclusively use Molybdenum Disilicide (MoSi₂) elements. At high temperatures, these elements form a protective quartz-glass layer on their surface that "self-heals," preventing further oxidation and allowing for stable, long-term operation.

Containing the Heat: Insulation and Refractories

Effective insulation is crucial for temperature stability and energy efficiency. Standard firebrick or low-grade ceramic fiber is inadequate.

These furnaces use multi-layered insulation packages, typically starting with an inner hot-face lining of high-purity alumina fiber or dense zirconia boards. This is backed by progressively lower-temperature insulation to create a steep thermal gradient within the furnace walls.

The Control System: Precision and Safety

Precision control is non-negotiable. Furnaces use a PID (Proportional-Integral-Derivative) controller to accurately manage heating ramps, soaking periods, and cooling rates.

For temperature measurement, a Type B thermocouple (Platinum-Rhodium) is the standard, as more common K-type or S-type thermocouples degrade or melt at these temperatures.

Managing the Atmosphere

The internal atmosphere of the furnace can be controlled for specific processes. Most 1800°C furnaces are designed to operate in air, which is required for the MoSi₂ elements to form their protective layer.

Specialized models can be adapted for inert gas atmospheres (like Argon) to prevent oxidation of the material being processed, though this adds complexity and cost.

Key Applications in Science and Industry

The ability to reach 1800°C unlocks processing capabilities for a range of high-performance materials.

Sintering Advanced Ceramics

This is the most common application. Materials like zirconia (used in dental crowns and industrial tooling) and alumina require these temperatures to achieve full density, hardness, and strength.

Crystal Growth and Annealing

Certain synthetic crystals used in lasers, optics, and electronics are grown or heat-treated at very high temperatures to achieve the required purity and crystalline structure.

High-Temperature Materials Research

Engineers and scientists use these furnaces to test the performance of new alloys, composites, and coatings designed for extreme environments, such as in aerospace or energy production.

Understanding the Operational Trade-offs

Operating at such high temperatures comes with significant challenges and limitations that users must respect.

The Brittleness of MoSi₂ Elements

While robust at high temperatures, MoSi₂ elements are extremely brittle at room temperature, like a piece of ceramic. They are easily broken by mechanical shock during installation or loading.

Thermal Shock Sensitivity

Rapid, uncontrolled heating or cooling can cause catastrophic failure. The ceramic insulation and the heating elements themselves can crack due to thermal shock, necessitating carefully programmed heating and cooling cycles.

High Energy Consumption

Maintaining 1800°C is an incredibly energy-intensive process. These furnaces represent a significant operational cost in terms of electricity consumption and place heavy demands on a facility's electrical infrastructure.

Contamination and Chemical Reactions

At these temperatures, materials become much more reactive. Chemical reactions between the material being processed, the furnace atmosphere, and the ceramic refractories can lead to contamination or degradation of either the product or the furnace itself.

Making the Right Choice for Your Application

To determine if a 1800°C furnace is necessary, consider the specific material and process requirements of your work.

- If your primary focus is research and development: A versatile box furnace with precise temperature control is essential for testing a wide range of advanced materials.

- If your primary focus is industrial production (e.g., dental zirconia): Durability, chamber uniformity, and reliable automation are more critical than maximum flexibility.

- If your primary focus is working below 1600°C: A furnace with Silicon Carbide (SiC) elements may offer a more cost-effective and robust solution.

Ultimately, a 1800°C furnace is a powerful tool engineered to push the boundaries of materials science.

Summary Table:

| Feature | Description |

|---|---|

| Max Temperature | 1800°C (3272°F) |

| Heating Element | Molybdenum Disilicide (MoSi₂) |

| Key Applications | Sintering advanced ceramics, crystal growth, materials research |

| Atmosphere | Air (standard) or inert gas (specialized) |

| Key Consideration | High energy consumption, thermal shock sensitivity |

Ready to push the boundaries of your materials research or production?

A 1800°C furnace is a significant investment, and choosing the right model is critical for your success. The experts at KINTEK specialize in high-temperature lab equipment and can help you select the perfect furnace for your specific application—whether it's sintering advanced ceramics like zirconia, conducting high-temperature materials testing, or scaling up for industrial production.

We understand the unique challenges of operating at extreme temperatures and provide solutions that ensure safety, precision, and reliability. Contact us today to discuss your requirements and let our expertise guide you to the optimal solution for your laboratory's needs.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?