In industrial processing, a carbon regeneration kiln is a high-temperature furnace designed to restore the adsorptive properties of "spent" activated carbon. It works by heating the carbon in a controlled, low-oxygen environment to a temperature high enough—typically around 700°C (1300°F)—to vaporize and burn off the organic contaminants it has collected. This process effectively cleans the carbon, allowing it to be reused multiple times.

The core purpose of a carbon regeneration kiln is to transform a high-volume industrial consumable into a reusable asset. By thermally stripping away impurities, it significantly lowers the operational costs and environmental impact associated with using single-use activated carbon.

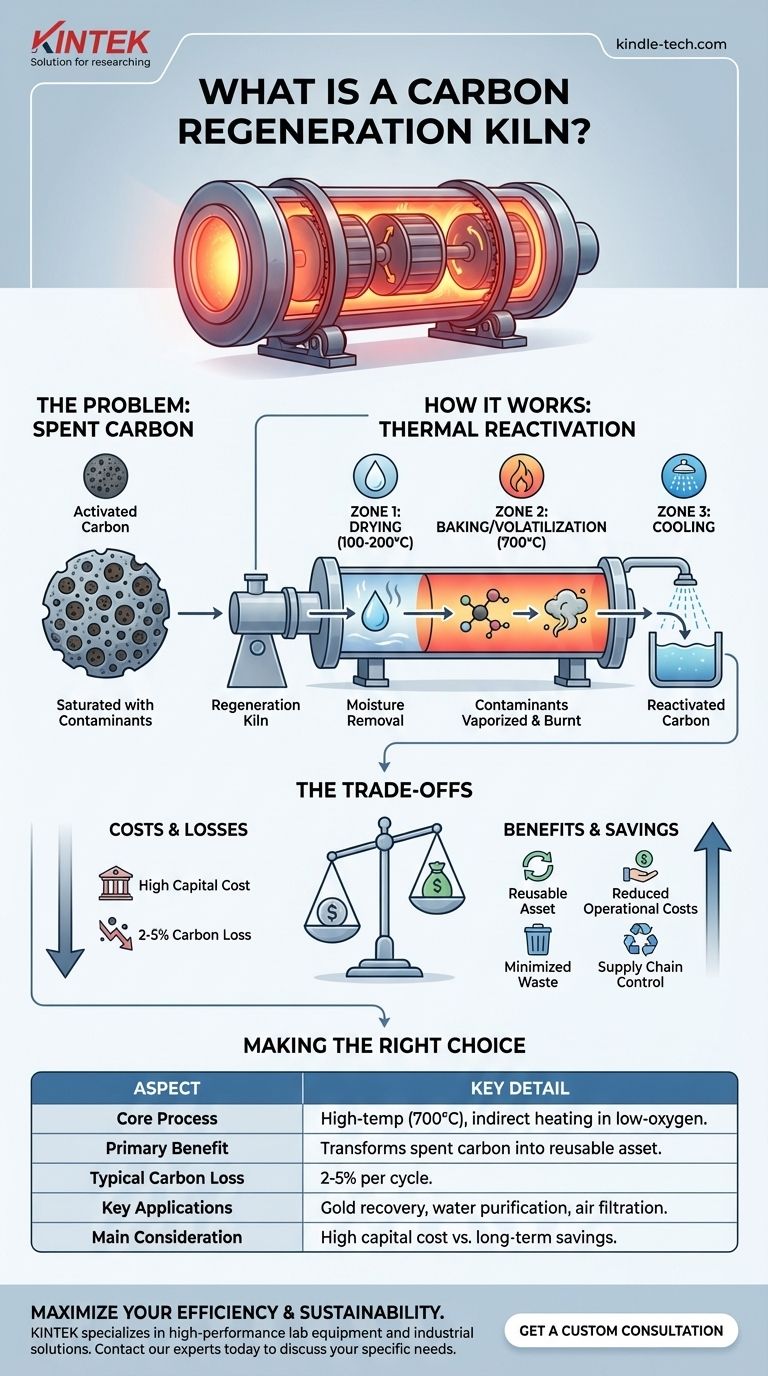

The Problem: Why Carbon Needs Regeneration

What is Activated Carbon?

Activated carbon is a form of carbon processed to have an incredibly large surface area due to its vast network of small, low-volume pores. Think of it as a highly porous sponge on a microscopic level.

This structure makes it an exceptional adsorbent, meaning molecules from gases or liquids stick to its surface.

The Adsorption Process

In applications like gold recovery, water purification, or air filtration, a stream containing contaminants is passed through a bed of activated carbon. The carbon's massive surface area acts like a magnet, trapping target molecules (like gold cyanide complexes or organic pollutants) while allowing the purified stream to pass through.

When Carbon Becomes "Spent"

Over time, the carbon's microscopic pores become filled with the adsorbed contaminants. Once saturated, it can no longer effectively capture new molecules and is considered "spent" or "loaded." At this point, it must either be replaced or regenerated.

How a Regeneration Kiln Works

The Principle of Thermal Reactivation

The regeneration process uses intense heat to reverse the adsorption process. The high temperature provides the energy needed to break the bonds holding the contaminants to the carbon's surface.

These contaminants are then either vaporized or broken down (pyrolyzed) into elemental carbon and volatile gases, which are carried away.

Indirect Firing: The Critical Design

Most modern regeneration kilns are indirectly fired. This means the activated carbon is contained within a rotating steel drum that is heated from the outside.

The carbon never comes into direct contact with the burner flame. This is crucial because it allows for precise temperature control and prevents a low-oxygen atmosphere from being contaminated, which protects the activated carbon from being consumed and lost to combustion.

The Stages of Regeneration

The process occurs in distinct temperature zones as the carbon travels through the rotating kiln:

- Drying: In the initial zone, moisture is driven off at temperatures around 100-200°C.

- Baking/Volatilization: In the central, hottest zone (around 700°C), the adsorbed organic contaminants are vaporized and pyrolyzed. A steam injection is often used here to facilitate the process and help clear the pores.

- Cooling: The reactivated carbon is then discharged into a quench tank, where it is rapidly cooled with water to stop any further reactions and prepare it for reuse.

Improving Energy Efficiency

To reduce fuel consumption, many systems incorporate a recycle duct. This captures the hot, clean exhaust gas from the kiln's heating chamber and uses it to pre-heat the combustion air, improving the overall thermal efficiency of the furnace.

Understanding the Trade-offs

Inevitable Carbon Loss

The regeneration process is not perfectly efficient. With each thermal cycle, a small percentage of the activated carbon (typically 2-5%) is lost. Some carbon is physically broken down into fine particles, and some is consumed in minor chemical reactions.

High Capital Cost

A regeneration kiln represents a significant upfront capital investment. The decision to purchase one depends on a careful analysis of the volume of carbon used, disposal costs, and the price of new replacement carbon.

Environmental Controls

The gases driven off the carbon during regeneration are pollutants and must be treated before being released into the atmosphere. This typically requires an afterburner or thermal oxidizer to combust the volatile organic compounds, followed by a scrubber to remove any harmful inorganic elements.

Making the Right Choice for Your Operation

Deciding whether to invest in a carbon regeneration kiln requires balancing economic and environmental goals.

- If your primary focus is cost reduction: For operations that consume large quantities of activated carbon, the savings from reusing carbon can lead to a return on investment in as little as one to two years.

- If your primary focus is environmental sustainability: Regeneration dramatically reduces the carbon footprint of your operation by minimizing landfill waste and eliminating the energy-intensive process of manufacturing and shipping new carbon.

- If your primary focus is supply chain control: An on-site kiln provides independence from carbon suppliers, insulating your operation from price volatility and potential lead-time issues.

By understanding the principles of regeneration, you can make an informed decision that aligns with your financial, operational, and environmental objectives.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Core Process | High-temperature (700°C), indirect heating in a low-oxygen environment. |

| Primary Benefit | Transforms spent carbon from a consumable into a reusable asset. |

| Typical Carbon Loss | 2-5% per regeneration cycle. |

| Key Applications | Gold recovery, water purification, air filtration. |

| Main Consideration | High upfront capital cost versus long-term savings on carbon replacement. |

Maximize your operational efficiency and sustainability.

If your operation uses activated carbon for purification or recovery, the long-term savings from an on-site regeneration kiln can be substantial. KINTEK specializes in high-performance lab equipment and industrial solutions, including systems for thermal processing. Our expertise can help you determine if carbon regeneration is the right choice to reduce costs, minimize waste, and gain control over your supply chain.

Contact our experts today to discuss your specific needs and explore how we can support your goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the principles of a rotary kiln? Master the Mechanics of High-Temperature Processing

- What is the temperature of a rotary hearth furnace? Find the Right Heat for Your Process

- What temperature is needed for porcelain? A Guide to Cone 6 and Cone 10 Firing

- What temperature is a carbon regeneration kiln? Master the 650°C-800°C Range for Optimal Results