At its core, a ceramic dental furnace is a specialized, high-temperature oven used by dental technicians to create durable and aesthetic dental restorations. It uses precisely controlled heat, and sometimes pressure, to transform ceramic materials into their final hardened state for products like crowns, bridges, inlays, and onlays.

A dental furnace is not a simple oven; it is a precision instrument that executes specific heating programs. Its fundamental purpose is to convert fragile ceramic powders or ingots into a strong, permanent restoration that flawlessly mimics the appearance and function of a natural tooth.

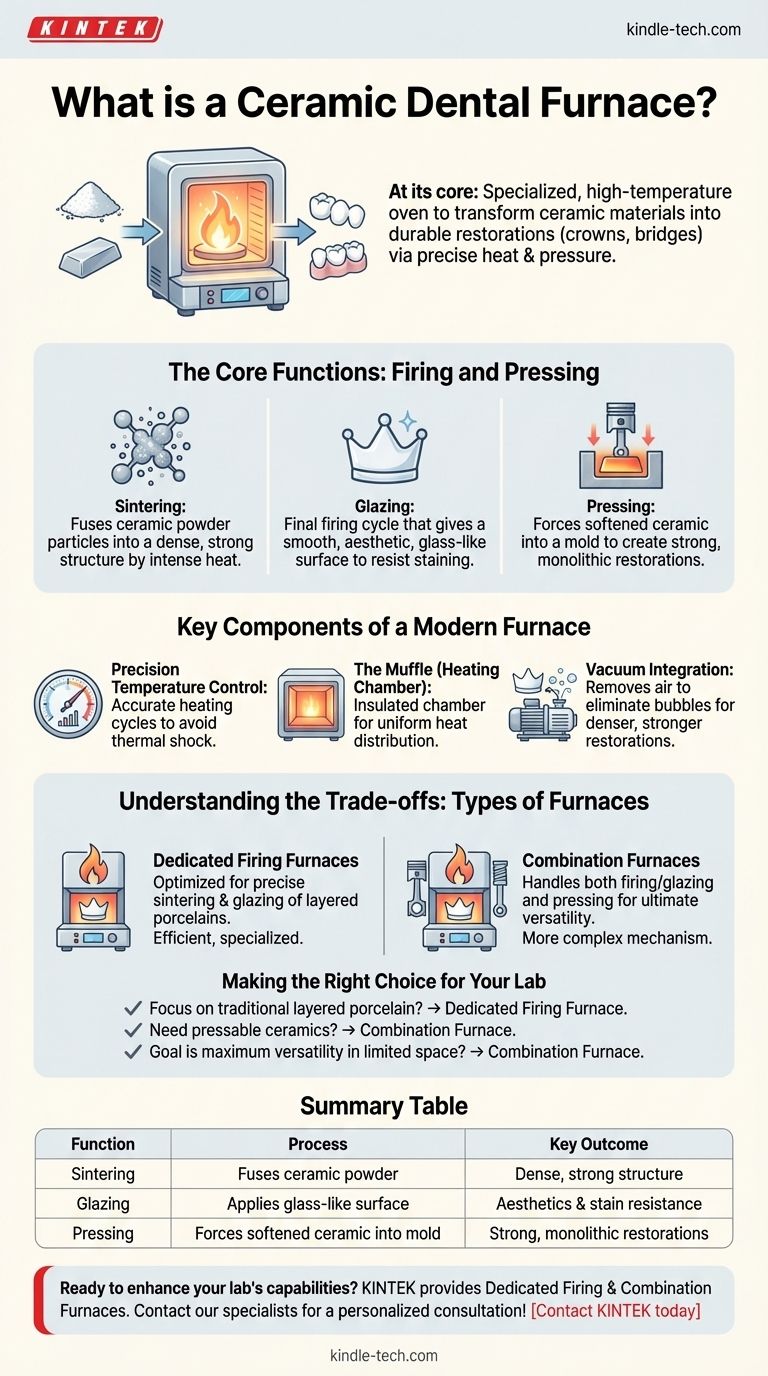

The Core Functions: Firing and Pressing

A dental furnace is responsible for several critical stages in the fabrication of a ceramic restoration. The processes it performs are dictated by the type of ceramic material and the desired final outcome.

Firing and Sintering

Sintering is the primary process for most dental porcelains. The furnace heats the ceramic material to a high temperature, just below its melting point.

This intense heat causes the individual ceramic particles to fuse, creating a dense, solid, and strong structure from what was once a fragile powder.

Glazing

Glazing is a final firing cycle that gives the restoration its smooth, glass-like, and lifelike surface.

This is not just for aesthetics; the non-porous glazed surface also helps prevent plaque accumulation and resists staining over time.

Pressing

Some furnaces are designed for "pressable" ceramics. In this process, a pre-made ceramic ingot is heated until it becomes viscous.

The furnace then uses pressure to force this softened material into a mold, which was created from a wax pattern of the final restoration. This is a common method for creating strong, monolithic crowns and veneers.

Key Components of a Modern Furnace

While designs vary, all high-quality dental furnaces rely on the same fundamental principles and components to achieve consistent, high-quality results.

Precision Temperature Control

The most critical feature is the ability to follow a complex, pre-programmed heating cycle. The furnace must raise, hold, and lower the temperature with extreme accuracy to ensure the ceramic matures properly without thermal shock or distortion.

The Muffle (Heating Chamber)

This is the insulated chamber where the restoration is placed. It is designed to provide uniform heat distribution, ensuring the entire restoration is fired evenly.

Vacuum Integration

During the sintering process, a vacuum pump is used to remove air from the muffle. This eliminates bubbles and impurities within the porcelain, resulting in a stronger, denser, and more translucent restoration.

Understanding the Trade-offs: Types of Furnaces

Not all furnaces perform the same functions. The primary distinction lies in their ability to handle both standard firing and the high-pressure demands of pressable ceramics.

Dedicated Firing Furnaces

These are the workhorses of many dental labs, designed exclusively for the sintering and glazing of layered porcelains. They are optimized for precise temperature and vacuum control for traditional crown and bridge work.

Combination Furnaces

As the name implies, a combination furnace is engineered to handle both firing/glazing and pressing. This versatility allows a lab to work with a wider range of materials, including popular pressable ceramics, all within a single machine.

This saves space and initial investment but requires a more complex internal mechanism to manage both heat and pneumatic pressure systems.

Making the Right Choice for Your Lab

Selecting the right furnace depends entirely on the services your laboratory offers and the materials you intend to use.

- If your primary focus is traditional layered porcelain work: A dedicated firing furnace provides an efficient and specialized tool for sintering and glazing.

- If you need to produce restorations from pressable ceramics: A combination furnace with pressing capabilities is an absolute requirement.

- If your goal is maximum versatility in a limited space: A combination furnace offers the ability to handle the widest array of ceramic materials in a single footprint.

Ultimately, the right dental furnace is the one that aligns precisely with the materials and restoration types your laboratory specializes in.

Summary Table:

| Function | Process | Key Outcome |

|---|---|---|

| Sintering | Fuses ceramic powder particles | Creates a dense, strong structure |

| Glazing | Applies a final glass-like surface | Provides aesthetics and stain resistance |

| Pressing | Forces softened ceramic into a mold | Forms strong, monolithic restorations |

Ready to enhance your lab's capabilities?

The right dental furnace is the cornerstone of producing high-quality, durable restorations. Whether you specialize in traditional layered porcelain or modern pressable ceramics, KINTEK has the expertise and equipment to meet your needs.

We provide:

- Dedicated Firing Furnaces: Optimized for precise sintering and glazing.

- Combination Furnaces: For ultimate versatility, handling both firing and pressing in one machine.

Let our specialists help you select the perfect furnace to streamline your workflow and expand your service offerings. Contact KINTEL today for a personalized consultation!

Visual Guide

Related Products

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- 1200℃ Muffle Furnace Oven for Laboratory

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is the sputtering voltage of a magnetron? Optimize Your Thin Film Deposition Process

- What are some positive and negative environmental effects of using biomass? A Balanced Look at a Renewable Energy Source

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What function does a high-temperature sintering furnace serve in biomass carbonization? Unlock Superior MFC Performance