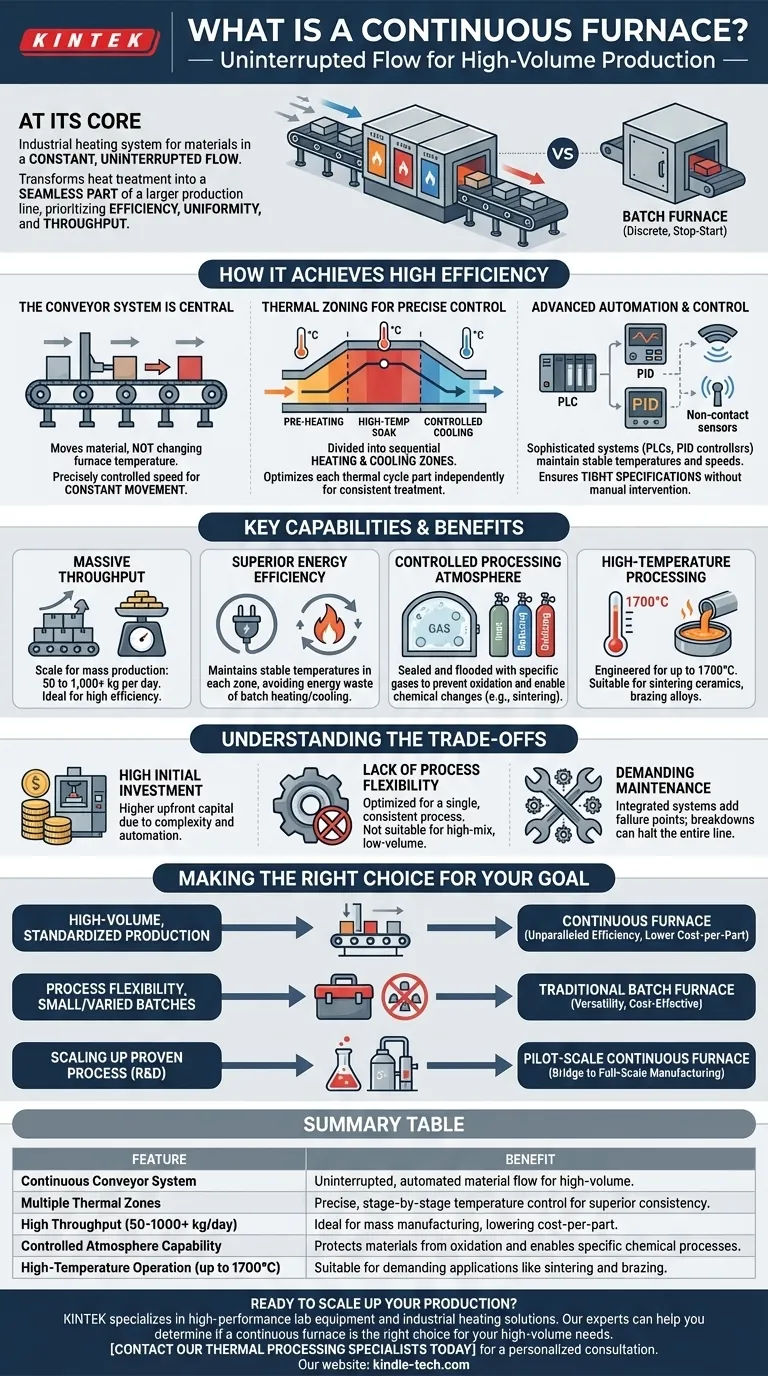

At its core, a continuous furnace is an industrial heating system designed to process materials in a constant, uninterrupted flow. Unlike a batch furnace that heats a single, static load at a time, a continuous furnace uses a conveying system to move products through different temperature zones, enabling high-volume and highly consistent automated production.

The fundamental advantage of a continuous furnace is its ability to transform heat treatment from a discrete, stop-and-start task into a seamless part of a larger production line. This design prioritizes efficiency, uniformity, and throughput for mass manufacturing.

How a Continuous Furnace Achieves High Efficiency

A continuous furnace operates on the principle of moving the material, not changing the furnace's temperature. This allows for an optimized and highly repeatable thermal process.

The Conveyor System Is Central

The defining feature is its conveying mechanism, such as a belt, roller hearth, or pusher system. This transports materials into, through, and out of the furnace at a precisely controlled speed.

This constant movement is the key difference from a batch furnace, where materials are loaded, the furnace is sealed, heated, cooled, and then unloaded in a much slower cycle.

Thermal Zoning for Precise Control

A continuous furnace is not one single temperature. It is divided into distinct heating and cooling zones that the material passes through sequentially.

A typical profile might include a pre-heating zone, one or more high-temperature "soak" zones, and controlled cooling zones. This allows each part of the thermal cycle to be optimized independently, ensuring every product receives the exact same treatment.

Advanced Automation and Control

Modern continuous furnaces are managed by sophisticated control systems. Programmable Logic Controllers (PLCs) and PID controllers maintain stable temperatures and precise conveyor speeds.

Features like non-contact temperature monitoring and step-less power control ensure the process remains within tight specifications without manual intervention, leading to exceptional product consistency.

Key Capabilities and Benefits

The design of a continuous furnace directly translates to tangible benefits for industrial-scale operations.

Massive Throughput

Continuous furnaces are built for scale. Throughput can range from 50 to over 1,000 kg per day, making them the ideal choice for mass production environments where efficiency is paramount.

Superior Energy Efficiency

By maintaining stable operating temperatures in each zone, a continuous furnace avoids the massive energy waste of repeatedly heating and cooling a large thermal mass, which is inherent to batch processing.

Controlled Processing Atmosphere

Many processes, such as sintering metal powders, require a specific atmosphere to prevent oxidation. Continuous furnaces can be sealed and flooded with inert, reducing, or oxidizing gases to protect the material and achieve desired chemical changes.

High-Temperature Processing

These systems are engineered for demanding applications, often reaching process temperatures as high as 1700°C. This makes them suitable for sintering advanced ceramics, brazing complex alloys, and other high-temperature metallurgical processes.

Understanding the Trade-offs

While powerful, a continuous furnace is not a universal solution. Understanding its limitations is critical for making an informed decision.

High Initial Investment

The complexity, size, and automation of a continuous furnace mean it represents a significantly higher upfront capital investment compared to a simpler batch furnace.

Lack of Process Flexibility

These furnaces are optimized for a single, consistent process. Changing the temperature profile or product type is a major undertaking that requires recalibration and downtime, making them unsuitable for high-mix, low-volume production.

Demanding Maintenance

The integrated conveying system and complex controls add more potential points of failure. Maintenance can be more involved, and a breakdown in any part of the system can halt the entire production line.

Making the Right Choice for Your Goal

The decision to use a continuous furnace should be driven by your specific production needs and scale.

- If your primary focus is high-volume, standardized production: A continuous furnace offers unparalleled efficiency, consistency, and a lower cost-per-part once operational.

- If your primary focus is process flexibility for small or varied batches: A traditional batch furnace is a far more practical and cost-effective choice for its versatility.

- If your primary focus is scaling up a proven process from R&D: A smaller, pilot-scale continuous furnace can be the perfect bridge to validate a process for full-scale manufacturing.

Ultimately, selecting the right furnace is a strategic decision based on a clear understanding of your production volume, process requirements, and long-term operational goals.

Summary Table:

| Feature | Benefit |

|---|---|

| Continuous Conveyor System | Enables uninterrupted, automated material flow for high-volume production. |

| Multiple Thermal Zones | Provides precise, stage-by-stage temperature control for superior product consistency. |

| High Throughput (50-1000+ kg/day) | Ideal for mass manufacturing, significantly lowering cost-per-part. |

| Controlled Atmosphere Capability | Protects materials from oxidation and enables specific chemical processes. |

| High-Temperature Operation (up to 1700°C) | Suitable for demanding applications like sintering and brazing. |

Ready to scale up your production with a continuous furnace?

KINTEK specializes in high-performance lab equipment and industrial heating solutions. Our experts can help you determine if a continuous furnace is the right choice for your high-volume manufacturing needs, ensuring you achieve maximum efficiency, consistency, and throughput.

Contact our thermal processing specialists today for a personalized consultation and discover how we can optimize your production line.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the range of pyrolysis? Master Temperature Control for Optimal Bio-Product Yields

- What is the difference between pyrolysis combustion and gasification? A Guide to Thermal Conversion Technologies

- What temperature is needed for pyrolysis waste? A Guide to Optimizing Your Waste-to-Value Process

- How is a high-temperature calcination furnace utilized in BZY20 Sol-gel? Achieve Pure Cubic Perovskite Phases

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity