At its core, a crucible furnace is one of the simplest and most fundamental types of furnaces used in metal casting. It functions by heating a durable, pot-like container—the crucible—from the outside. The material to be melted, known as the charge, is placed inside the crucible, and as the container heats up, the charge melts into a liquid state ready for pouring.

A crucible furnace is a straightforward and versatile tool for melting small batches of various materials. Its key characteristic is indirect heating, where the heat source never touches the metal, making it ideal for applications demanding high purity and flexibility, but less efficient for large-scale industrial production.

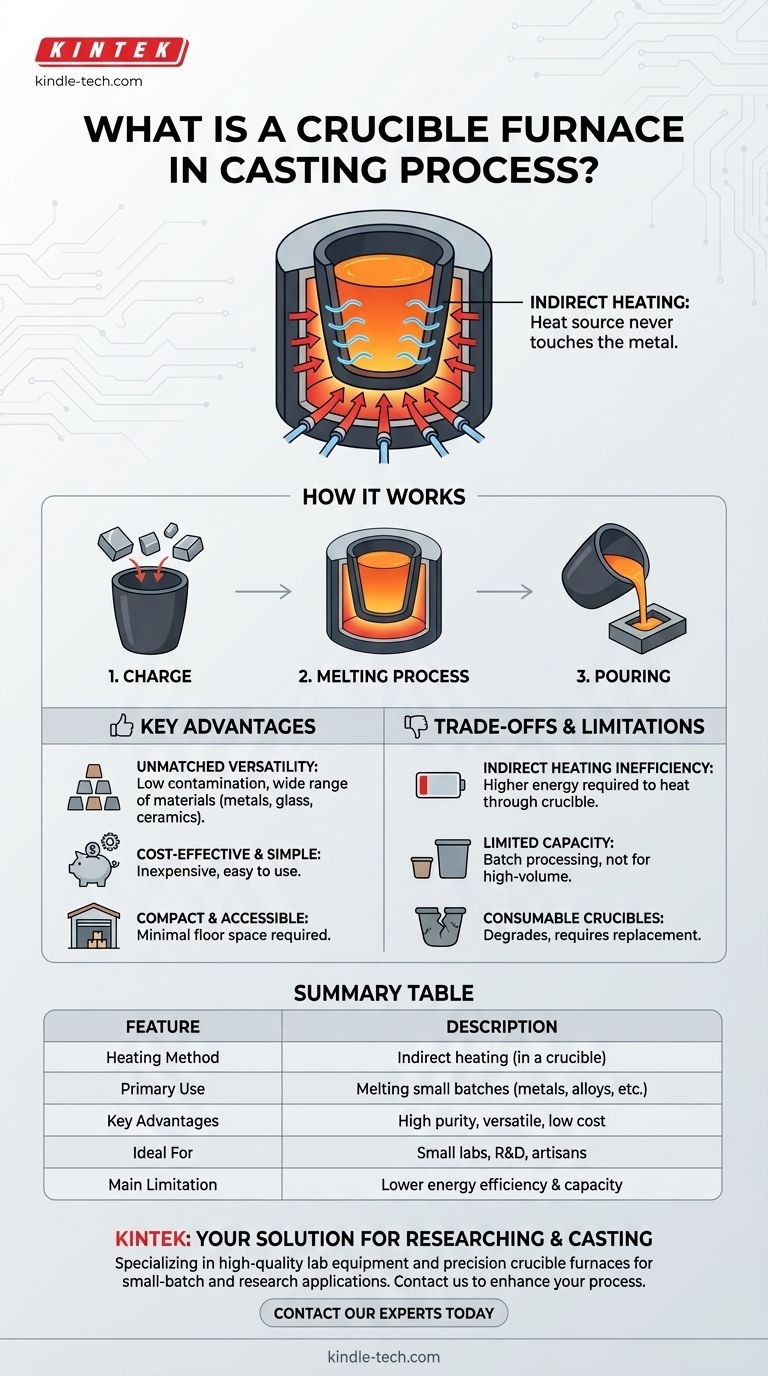

How a Crucible Furnace Works

A crucible furnace's operation is based on a simple principle of heat transfer. Understanding its components and process reveals its strengths and limitations.

The Core Components

The furnace consists of two primary parts. The first is the crucible, a container made from a refractory material like ceramic or clay-graphite that can withstand extreme temperatures. The second is the furnace body, which houses the crucible and contains the heating source—either gas-fired burners or electric resistance heating elements.

The Melting Process

The process begins by placing a solid charge of metal or another material into the crucible. Heat is then generated by the burners or electric elements in the furnace chamber. This heat transfers through the air and then through the crucible's wall to the material inside, gradually raising its temperature to its melting point.

Temperature Management

Once the material is molten, the furnace maintains the required temperature until it is ready to be poured into a mold. Modern crucible furnaces often include precise temperature control systems, allowing the operator to manage the process accurately for different materials and alloys.

Key Advantages in Modern Casting

Despite being one of the oldest furnace designs, the crucible furnace remains relevant due to several distinct advantages, particularly for smaller operations.

Unmatched Material Versatility

Because the molten material is always contained within the crucible and never contacts the heating elements, there is a very low risk of contamination. This makes these furnaces excellent for melting a wide range of materials, including various metals, alloys, glass, and ceramics.

Cost-Effectiveness and Simplicity

Crucible furnaces are relatively inexpensive to purchase and operate compared to more complex industrial furnaces. Their straightforward design makes them easy to use, making them a popular choice for small foundries, laboratories, artisans, and hobbyists.

Compact and Accessible Design

These furnaces are typically compact, requiring minimal floor space. This makes them perfectly suited for small-scale workshops or research environments where space is a primary consideration.

Understanding the Trade-offs and Limitations

The same simplicity that makes the crucible furnace advantageous also creates its primary limitations, especially when scaling up production.

Indirect Heating Inefficiency

The primary drawback is the inefficiency of indirect heating. A significant amount of energy is required to heat the furnace chamber and then transfer that heat through the crucible wall. This is less energy-efficient than direct heating methods used in larger, industrial furnaces.

Limited Capacity and Scale

By their very nature, crucibles are designed for batch processing and have a limited volume. This makes them impractical for the high-volume, continuous melting operations required in major industrial foundries.

Reliance on Consumable Crucibles

The crucible itself is a consumable item. While made of durable refractory materials, it degrades over time due to thermal shock and chemical reactions with the molten metal, requiring periodic replacement.

Making the Right Choice for Your Goal

Selecting a crucible furnace depends entirely on the scale and requirements of your casting operation.

- If your primary focus is small-batch casting, research, or artistic work: A crucible furnace offers an excellent balance of cost, versatility, and precise control for a wide variety of materials.

- If your primary focus is high-volume industrial production: The capacity and energy efficiency limitations make a crucible furnace unsuitable; more advanced furnace types are necessary.

Ultimately, recognizing the role of the crucible furnace provides a clear baseline for evaluating all other melting technologies in the casting industry.

Summary Table:

| Feature | Description |

|---|---|

| Heating Method | Indirect heating (material is contained in a crucible) |

| Primary Use | Melting small batches of metals, alloys, glass, or ceramics |

| Key Advantages | High material purity, versatility, cost-effectiveness, simple operation |

| Ideal For | Small foundries, laboratories, artisans, hobbyists, R&D |

| Main Limitation | Lower energy efficiency and capacity vs. large industrial furnaces |

Ready to find the perfect melting solution for your lab or workshop?

KINTEK specializes in high-quality lab equipment, including crucible furnaces designed for precision, versatility, and reliability. Whether you're in research, development, or small-scale production, our solutions help you achieve pure melts and consistent results.

Contact our experts today to discuss your specific needs and how our equipment can enhance your casting process!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results