In heat treatment, a furnace is far more than just a source of heat. It is a precisely engineered industrial system designed to modify a material's properties by subjecting it to a controlled thermal cycle. Critically, this thermal cycle takes place within a specific, managed atmosphere, making the furnace a complete environmental control chamber.

The essential function of a heat treatment furnace is not merely to heat a material, but to do so with precise temperature control inside a deliberately managed atmosphere. This combination is what enables the intentional modification of a material's internal structure and surface chemistry.

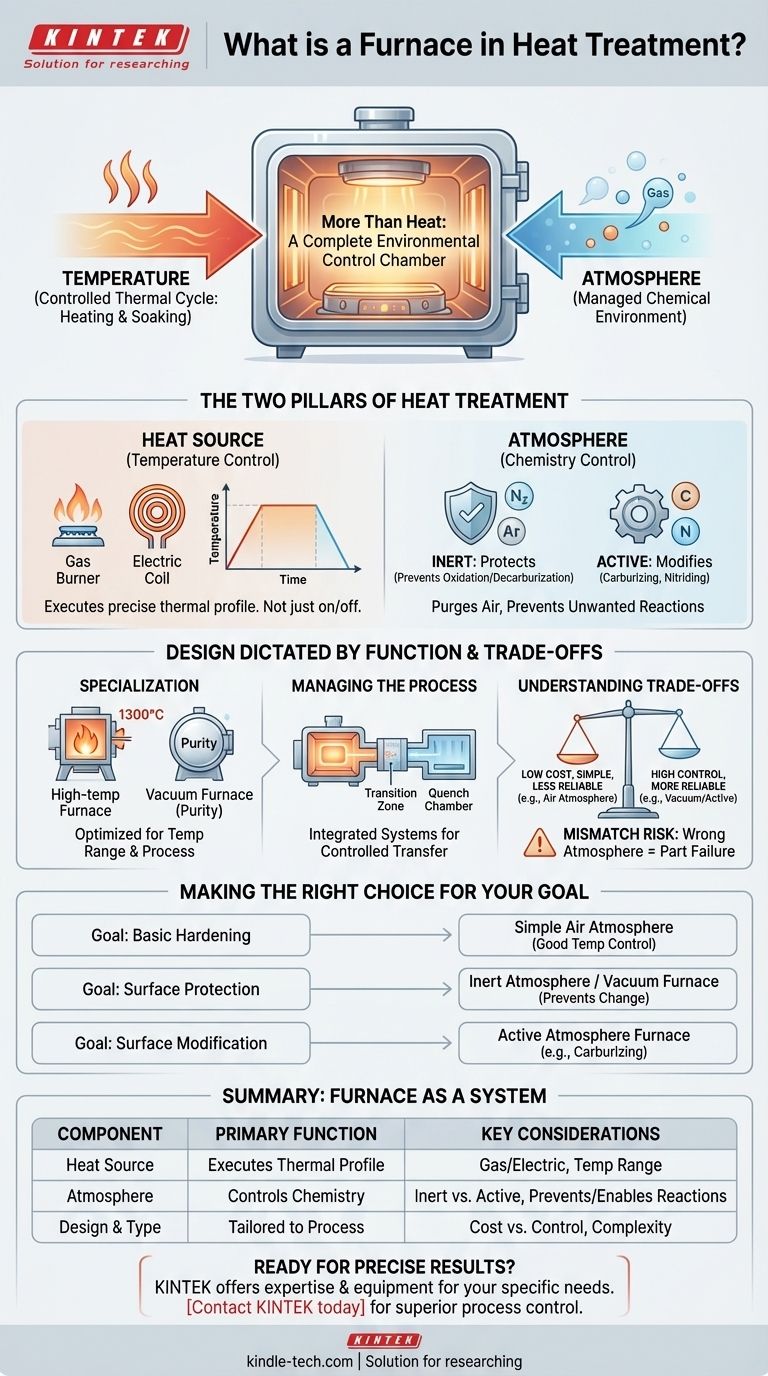

The Two Pillars of Heat Treatment: Temperature and Atmosphere

Understanding a furnace requires looking at its two primary components: the heat source that controls the temperature and the internal atmosphere that controls the chemistry.

The Role of the Heat Source

The heat source, which can be gas-fueled or electrically energized, is responsible for executing a specific thermal profile.

This isn't a simple "on/off" process. It involves a "heating period" where significant energy is used to bring the material and the chamber to the target temperature, followed by a "soaking period" where the heat is carefully regulated to maintain that temperature consistently.

Why the Atmosphere is Critical

The atmosphere inside the sealed furnace chamber is just as important as the temperature. It is an active component in the process.

A furnace's atmosphere is used to purge air (and thus oxygen) to prevent unwanted reactions on the material's surface.

Depending on the goal, the atmosphere can prevent oxidation (scaling) and decarburization (the loss of carbon from the surface of steel), preserving the material's integrity. Conversely, it can also be used to intentionally introduce chemical species like carbon for carburizing or nitrogen for nitriding, which hardens the surface.

Active vs. Inert Atmospheres

Furnace atmospheres fall into two categories. Inert atmospheres, such as nitrogen or argon, are used to protect the material from chemical changes.

Active atmospheres are designed to react with the material's surface. The choice between them depends entirely on the desired outcome, the material type, and cost considerations.

Furnace Design is Dictated by Function

No single furnace design is perfect for all tasks. The physical construction of a furnace is determined by the specific heat treatment process it must perform.

Temperature Range Specialization

A furnace designed for very high temperatures (e.g., 1300°C) is often inefficient and may lack the fine control needed for low-temperature processes (e.g., 300°C). Equipment is specialized for its intended operational range to ensure accuracy and efficiency.

Process-Specific Designs

Different processes demand fundamentally different furnaces. A vacuum furnace, for example, removes the atmosphere entirely to perform functions like high-purity brazing, sintering, or gas quenching without any surface contamination.

Managing the Entire Process

A furnace is often part of a larger system. For instance, some setups include a "back room" or transition chamber. This allows workpieces to be moved from the heat into a controlled environment before quenching, preventing oxidation that would occur if exposed to open air while hot.

Understanding the Trade-offs

Choosing and operating a heat treatment furnace involves balancing competing factors. Being aware of these trade-offs is crucial for success.

Cost vs. Control

A simple furnace open to the air is the cheapest to operate but offers zero atmospheric control. As you move to inert gases and finally to active or vacuum atmospheres, the level of process control increases dramatically, but so do the equipment and operational costs.

Complexity vs. Reliability

The more complex the atmosphere and thermal cycle, the more variables there are to manage. Advanced processes like carburizing require extremely tight control over gas composition and temperature, increasing the potential for error if not managed meticulously.

Material and Process Mismatch

Using the wrong atmosphere is one of the most common failures in heat treatment. Attempting to heat a sensitive tool steel in an oxygen-rich atmosphere will lead to scaling and decarburization, potentially ruining the part. The furnace environment must be compatible with the material and the desired outcome.

Making the Right Choice for Your Goal

The correct furnace approach is the one that meets the specific metallurgical requirements of your project.

- If your primary focus is basic hardening or tempering of non-sensitive steels: A simple air atmosphere furnace with excellent temperature control may be sufficient.

- If you must prevent any surface change like oxidation or decarburization: An inert atmosphere (like nitrogen or argon) or a vacuum furnace is necessary.

- If your goal is to intentionally change the surface chemistry (e.g., case hardening): You require a furnace capable of handling an active atmosphere for processes like carburizing or nitriding.

Ultimately, viewing the furnace as a complete environmental control system—not just a heater—is the key to achieving predictable and repeatable heat treatment results.

Summary Table:

| Furnace Component | Primary Function | Key Considerations |

|---|---|---|

| Heat Source | Executes a controlled thermal profile (heating & soaking). | Gas or electric; specialized for specific temperature ranges. |

| Atmosphere | Controls the chemical environment inside the chamber. | Inert (protective) or Active (surface-modifying); prevents oxidation or enables carburizing. |

| Design & Type | Tailored to the specific process and material requirements. | Ranges from simple air atmosphere to complex vacuum furnaces; involves trade-offs in cost vs. control. |

Ready to achieve precise and repeatable heat treatment results?

The right furnace is the cornerstone of successful material processing. Whether your goal is basic hardening, surface protection with an inert atmosphere, or advanced case hardening, KINTEK has the expertise and equipment to meet your laboratory's specific needs.

Contact KINTEL today to discuss how our specialized lab furnaces can enhance your process control and deliver superior outcomes for your materials.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why is precise heating rate control critical in sintering B4C-TiB2 ceramics? Master Structural Integrity

- How does a vacuum oven contribute to solid electrolyte membrane formation? Achieve Dense, Defect-Free Materials

- How do high-temperature sintering and melting systems assist V-Si-B alloys? Unlocking Performance for Nuclear Fusion

- What is the primary purpose of any heat treatment operation? To Tailor Material Properties for Performance

- What are the core capabilities of a fast pyrolysis furnace in producing lignin-derived bio-oil? Maximize Your Yield

- What is the critical function of a vacuum annealing furnace in MAX phase coating synthesis? Ensure Phase Purity Today

- What is a quench furnace? A Complete Guide to Controlled Hardening and Tempering

- What is the temperature range of an electric furnace? Achieve Safe, Efficient Home Heating