At its core, a laboratory press is a device designed to apply a precise and controlled amount of force to a sample. This force is typically delivered between two parallel plates, known as platens, which can often be heated or cooled. Its fundamental purpose is to prepare materials for analysis, test their physical properties, or form them into new shapes under controlled conditions.

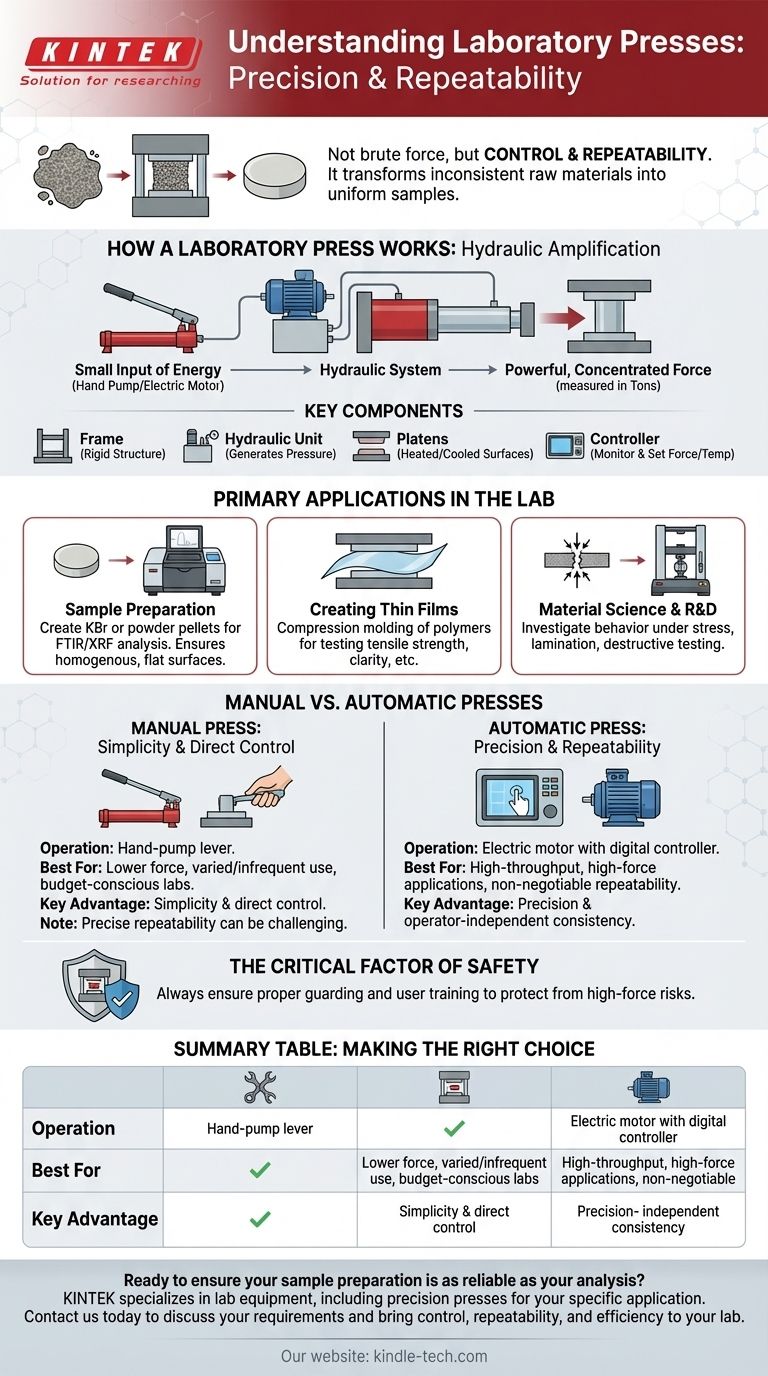

The primary value of a laboratory press is not brute force, but repeatability and control. It transforms inconsistent raw materials into standardized, uniform samples, which is the essential foundation for reliable and accurate scientific analysis.

How a Laboratory Press Works

A laboratory press translates a small input of energy—whether from a hand pump or an electric motor—into a powerful, concentrated force. This is almost always achieved through a hydraulic system.

The Core Principle: Hydraulic Amplification

The press operates on the principle of hydraulic multiplication. A pump moves fluid to build up pressure within a cylinder, which then drives a ram to close the platens and compress the sample.

This system allows for the generation of immense force (measured in tons) with minimal effort, providing the controlled pressure needed for sample preparation and material testing.

Key Components of the System

Every press consists of a few critical parts working in concert.

- The frame provides the rigid structure necessary to withstand the high forces generated.

- The hydraulic unit (manual or powered) generates the pressure.

- The platens are the flat, smooth surfaces that make direct contact with the sample or mold. They are often equipped with heating elements and cooling channels for temperature control.

- The controller or gauge allows the operator to monitor and set the desired force, temperature, and duration of the press cycle.

Primary Applications in the Lab

While the function is simple—apply pressure—the applications are diverse, spanning chemistry, material science, pharmaceuticals, and geology.

Sample Preparation for Analysis

This is the most common use. Many analytical techniques require samples to be in a specific, uniform format to produce accurate results.

A press is essential for creating KBr pellets for FTIR spectroscopy or pressed powder pellets for X-Ray Fluorescence (XRF) analysis. This process ensures the sample is homogenous and has a perfectly flat surface, which is critical for these measurement methods.

Creating Thin Films

For polymer science and materials research, a press with heated platens is used to melt a plastic resin or compound and press it into a thin, uniform film.

This process, known as compression molding, allows researchers to create consistent samples for testing properties like tensile strength, optical clarity, or chemical resistance.

Material Science and R&D

Beyond simple preparation, presses are used to investigate how materials behave under stress and heat.

They are used for lamination (bonding layers together), destructive testing (compressing a material until it fails to measure its strength), and creating composite materials.

Understanding the Trade-offs: Manual vs. Automatic

The most significant decision when selecting a press is choosing between a manual and an automatic model. This choice directly impacts workflow, precision, and cost.

The Manual Press: Simplicity and Direct Control

A manual lab press is operated with a hand pump. The user directly controls the application of force by pumping a lever.

These are excellent for lower-force applications, labs with varied but infrequent needs, or when budget is the primary constraint. However, achieving precise, repeatable pressure cycles can be challenging and operator-dependent.

The Automatic Press: Precision and Repeatability

An automatic lab press uses an electric motor to run the hydraulic pump. The user sets the desired force, temperature, and time on a digital controller, and the press executes the cycle automatically.

This is critical for high-throughput labs, applications requiring high forces, or any process where repeatability is non-negotiable. The result is consistent samples, independent of the operator.

The Critical Factor of Safety

Any machine generating tons of force presents inherent risks. Modern presses include safety shields to protect operators from sample fragmentation under pressure. It is crucial to ensure any press, whether manual or automatic, is equipped with proper guarding and that users are trained on safe operating procedures.

Making the Right Choice for Your Goal

Selecting the right press depends entirely on your specific laboratory application and desired outcome.

- If your primary focus is routine sample prep for spectroscopy (e.g., KBr pellets): A simple, low-tonnage manual press is often the most cost-effective and practical solution.

- If your primary focus is polymer research or high-throughput quality control: An automatic press with programmable heating and cooling cycles is essential for process control and repeatability.

- If your primary focus is material strength testing or high-force molding: A high-tonnage automatic press is required to deliver the necessary force with precision and safety.

Ultimately, choosing the right laboratory press is about ensuring your sample preparation is as reliable and controlled as your final analysis.

Summary Table:

| Feature | Manual Press | Automatic Press |

|---|---|---|

| Operation | Hand-pump lever | Electric motor with digital controller |

| Best For | Lower force, varied/infrequent use, budget-conscious labs | High-throughput, high-force applications, non-negotiable repeatability |

| Key Advantage | Simplicity and direct control | Precision and operator-independent consistency |

Ready to ensure your sample preparation is as reliable as your analysis?

The right laboratory press is the foundation for accurate FTIR, XRF, and material testing. KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision presses designed for your specific application—from routine sample prep to advanced polymer research.

Contact us today to discuss your requirements and discover how our solutions can bring control, repeatability, and efficiency to your lab.

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Double Plate Heating Press Mold for Lab

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What safety items must be used when using a hydraulic press? Essential PPE and Procedures to Prevent Accidents

- What is a BARS press? Discover the Engineering Secrets to Growing Large, Gem-Quality Diamonds

- What machine is used to make pellets? The Complete Guide to Pellet Mills & Production Systems

- What role does a laboratory hydraulic press play in all-solid-state battery electrode evaluation? Key Roles Explained

- How does a laboratory hydraulic press ensure the accuracy of test results? Master Precision Specimen Preparation

- Why is a laboratory hydraulic press required for SHS reaction? Master Powder Compaction for Optimal Synthesis

- How does a manual press work? Unlock Powerful Force Without Electricity

- How are laboratory hydraulic presses applied in thin film testing? Optimize Adhesion and Stress Analysis